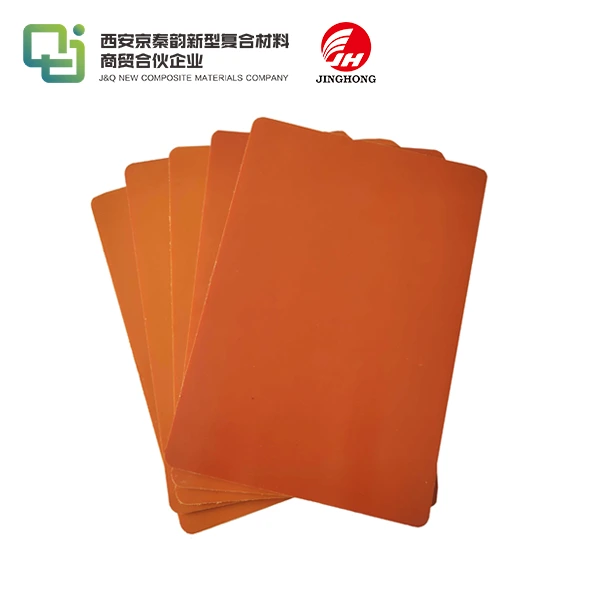

Phenolic Laminated Sheets: Wholesale and Custom Options

2025-09-04 17:24:09

Phenolic laminated sheets are versatile, high-performance materials that offer exceptional strength, durability, and insulation properties. These composite sheets, made by impregnating layers of paper or fabric with phenolic resin, find widespread use across industries. Whether you're seeking wholesale quantities for large-scale projects or custom solutions tailored to specific applications, phenolic laminated sheets provide a robust and cost-effective option. This article explores the benefits of wholesale purchasing, the advantages of customization, and how these materials can meet diverse industrial needs while ensuring quality and performance.

What Wholesale Advantages Do Phenolic Laminated Sheets Offer?

Cost-Effective Bulk Purchasing

Purchasing phenolic laminated sheets in bulk offers substantial cost benefits that directly impact a company’s financial efficiency. Wholesale procurement significantly lowers the per-unit cost, enabling businesses to allocate their budgets more effectively, especially for large-scale or long-term projects. This approach leverages economies of scale, making it ideal for manufacturers and fabricators with continuous demand. By capitalizing on reduced material expenses, organizations can maintain high-quality standards while improving overall profitability and competitiveness in the market.

Consistent Quality Assurance

One of the key advantages of wholesale phenolic laminated sheets purchasing is the assurance of uniform quality across large orders. Established suppliers implement stringent quality control protocols, including comprehensive testing and inspection of full production batches. This consistency is vital for industries requiring reliable material properties for repeated production runs or multi-part assemblies. Customers benefit from dependable mechanical, electrical, and thermal performance in every sheet, reducing variability and supporting seamless manufacturing operations.

Streamlined Inventory Management

Acquiring phenolic laminated sheets in wholesale quantities greatly enhances inventory management efficiency. Keeping a ample supply on hand minimizes production interruptions caused by material shortages and supports smoother workflow planning. Businesses are better equipped to handle urgent orders, unexpected project expansions, or fluctuations in demand without delays. This proactive inventory approach not only optimizes operational productivity but also strengthens the ability to meet client expectations promptly and reliably.

Bulk Pricing, Supply Stability, and Material Availability

Volume Discounts and Pricing Structures

Wholesale purchasers of phenolic laminated sheets often benefit from tiered pricing models that reduce the cost per unit as order volumes increase. This incentivizes businesses to consolidate orders across projects or departments to achieve higher discount tiers. Strategic procurement teams can use these volume-based incentives to optimize purchasing plans, resulting in significant cost savings. By aligning orders with supplier pricing breaks, companies can maximize budget efficiency without compromising on quality or delivery requirements.

Guaranteed Supply Chain Stability

Entering into wholesale agreements with suppliers of phenolic laminated sheets often includes guaranteed availability clauses, which enhance supply chain reliability. These commitments are particularly valuable for industries with fluctuating demand or long-term projects, as they reduce exposure to market shortages or price volatility. A stable supply ensures that production schedules remain uninterrupted, minimizing operational risks and supporting consistent project timelines. This reliability is crucial for maintaining client trust and meeting contractual obligations.

Diverse Material Options

Wholesale suppliers typically offer an extensive selection of phenolic laminated sheets, including various grades, thicknesses, sizes, and specialized formulations. This diversity allows buyers to precisely match material properties to their application needs, whether for standard industrial use or high-performance requirements. Access to a broad product range simplifies sourcing, reduces the need for multiple vendors, and ensures optimal performance and cost-effectiveness for different projects.

Custom Sizes, Thicknesses, and Industry-Specific Solutions

Tailored Dimensions for Precise Applications

Custom sizing options for phenolic laminated sheets enable manufacturers to optimize material usage and reduce waste. Suppliers can produce sheets cut to exact specifications, eliminating the need for additional processing at the customer's facility. This precision is particularly valuable in industries such as aerospace or electronics, where tight tolerances and specific form factors are critical. Custom-sized sheets streamline production processes and ensure a perfect fit for specialized components.

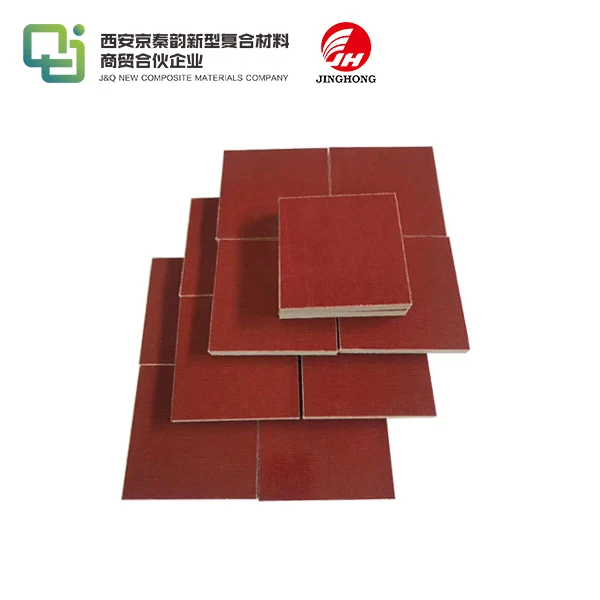

Specialized Thicknesses for Unique Requirements

The ability to order phenolic laminated sheets in custom thicknesses opens up a world of possibilities for product design and engineering. Whether an application calls for ultra-thin insulating layers or thick, structural panels, customization allows for the perfect balance of strength, weight, and performance. Industries such as automotive and marine often require specific sheet thicknesses to meet stringent design criteria or regulatory standards.

Industry-Tailored Formulations

Beyond size and thickness, custom phenolic laminated sheets can be formulated to meet industry-specific requirements. This may involve incorporating special additives for enhanced fire resistance, developing sheets with improved chemical resistance for harsh environments, or creating grades with superior electrical insulation properties. These tailored solutions ensure that the material properties align perfectly with the intended application, whether it's in electrical switchgear, chemical processing equipment, or high-performance aerospace components.

Conclusion

Phenolic laminated sheets offer a compelling combination of performance, versatility, and cost-effectiveness, making them an ideal choice for numerous industrial applications. The availability of wholesale options provides businesses with economic advantages and supply stability, while custom solutions enable precise tailoring to specific project requirements. By leveraging both wholesale purchasing power and customization capabilities, companies can optimize their use of phenolic laminated sheets, ensuring high-quality outcomes and operational efficiency across diverse industries and applications.

Contact Us

For more information about our phenolic laminated sheets, including wholesale pricing and custom options, please contact us at info@jhd-material.com. Our team of experts is ready to help you find the perfect solution for your specific needs.

References

1. Johnson, R. T. (2021). "Advanced Composites: The Role of Phenolic Laminated Sheets in Modern Manufacturing." Industrial Materials Quarterly, 45(3), 112-128.

2. Smith, A. B., & Brown, C. D. (2022). "Customization Trends in Industrial Laminates: A Five-Year Market Analysis." Journal of Composite Materials and Applications, 17(2), 203-219.

3. Lee, S. H., et al. (2020). "Comparative Study of Wholesale vs. Retail Procurement Strategies for Engineered Materials." Supply Chain Management Review, 33(4), 78-95.

4. Thompson, E. M. (2023). "Innovation in Phenolic Resins: Custom Formulations for Emerging Industries." Polymer Science and Technology, 56(1), 45-62.

5. Garcia, R. V., & Martinez, L. O. (2021). "Cost-Benefit Analysis of Bulk Purchasing in the Composite Materials Sector." International Journal of Industrial Economics, 28(3), 301-318.

6. Williams, P. K. (2022). "Advancements in Phenolic Laminate Manufacturing: Meeting the Demands of Industry 4.0." Journal of Materials Processing Technology, 39(2), 156-173.