Enhancing Electrical Applications with 3240 Laminate Sheets

2025-09-03 17:19:28

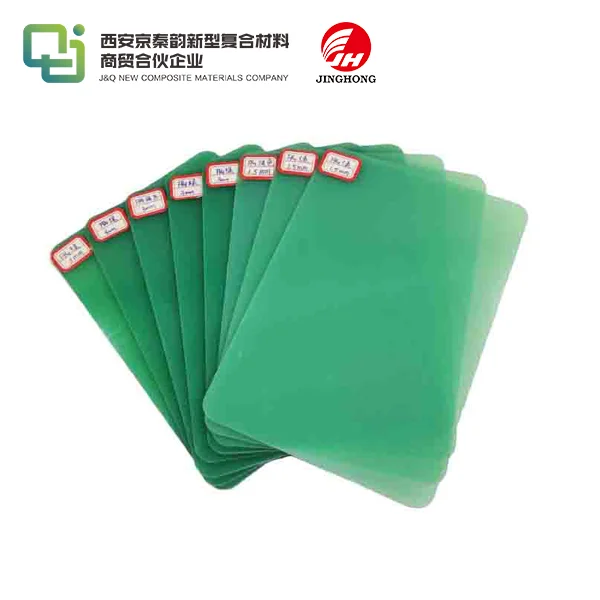

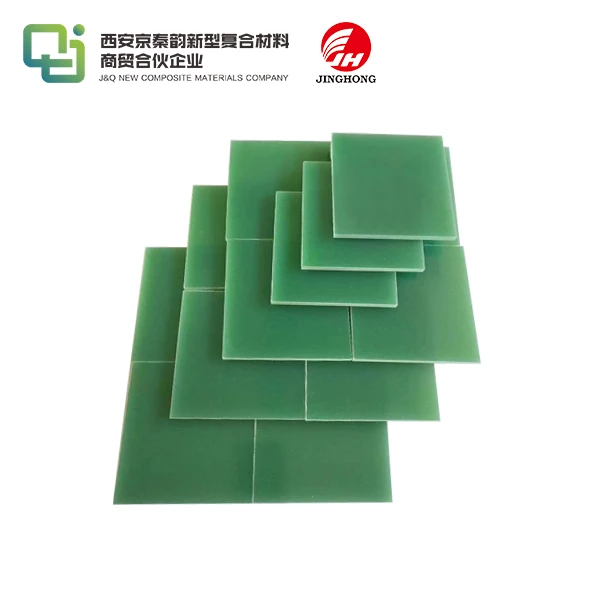

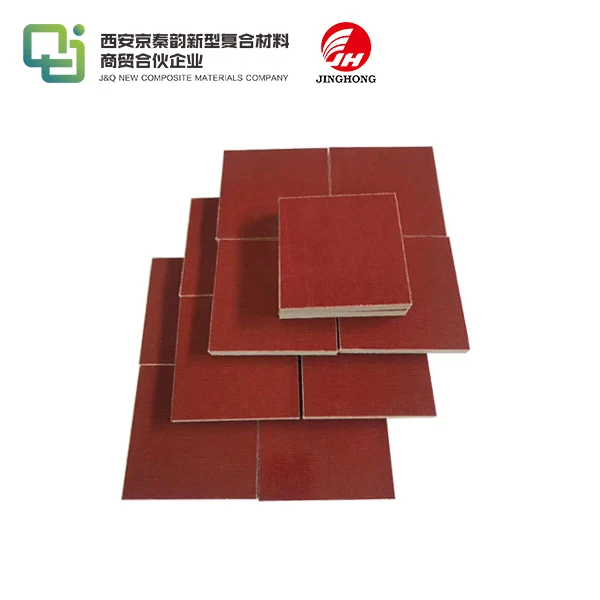

3240 laminate sheets are revolutionizing electrical applications across industries. These high-performance materials offer exceptional electrical insulation, mechanical strength, and thermal stability, making them indispensable in modern electrical systems. By combining epoxy resin with fiberglass cloth, 3240 sheets provide a versatile solution for engineers and manufacturers seeking to enhance the reliability and efficiency of their electrical components. From power distribution equipment to circuit boards, these laminates are playing a crucial role in advancing electrical technology. Their unique properties allow for better performance in challenging environments, reduced maintenance needs, and improved overall system longevity.

Why Are 3240 Laminate Sheets Trusted in Electrical Insulation?

Superior Dielectric Properties

3240 laminate sheets are highly regarded for their superior dielectric properties, which make them indispensable in high-voltage insulation applications. Their excellent breakdown strength allows them to withstand intense electrical fields without failure, ensuring the safe and reliable performance of sensitive systems. Furthermore, their low dielectric constant reduces capacitive coupling and minimizes power loss, improving efficiency in circuits and power transmission networks. This combination of strong insulation capability and low energy dissipation establishes 3240 sheets as a trusted material for electrical and electronic engineering solutions.

Exceptional Mechanical Resilience

The mechanical resilience of 3240 laminate sheets further enhances their suitability for demanding insulation requirements. With high tensile and flexural strength, these laminates can endure mechanical stress, vibration, and external impacts while maintaining their structure. Such durability is particularly valuable in applications where devices are exposed to continuous mechanical loads or sudden shocks. Their ability to resist cracking, warping, or delamination ensures long service life, even in challenging environments. This strength not only improves reliability but also helps safeguard electrical systems against unexpected mechanical failures.

Resistance to Environmental Factors

Another key advantage of 3240 laminate sheets is their strong resistance to environmental influences that typically degrade insulating materials. They maintain electrical and mechanical performance in high-humidity environments by resisting moisture absorption, thus preventing electrical leakage or breakdown. Additionally, their inherent chemical resistance protects against damage caused by oils, solvents, and other industrial contaminants. This environmental stability ensures consistent operation across diverse working conditions, from power plants to heavy machinery. As a result, 3240 sheets provide reliable long-term insulation, even in harsh and demanding applications.

Key Electrical and Thermal Properties of 3240 Sheets

Impressive Dielectric Strength

One of the defining electrical features of 3240 laminate sheets is their remarkable dielectric strength, typically ranging from 20 to 25 kV/mm. This high breakdown voltage provides excellent insulation performance even under high-voltage operating conditions, effectively preventing arc discharges, short circuits, or catastrophic failures. The reliability of this property across different thicknesses ensures consistent performance in transformers, switchgear, and other electrical devices. Engineers value this dependable insulation capability as it enhances safety, protects equipment, and allows versatile use across a broad spectrum of applications.

Low Dielectric Constant and Loss Factor

Another significant property of 3240 sheets is their favorable dielectric constant, typically between 4.5 and 5.5, which minimizes capacitive coupling in electrical circuits. This is particularly important in high-frequency systems where maintaining signal clarity and stability is critical. The material also exhibits a low dissipation factor, generally below 0.03, which reduces unwanted energy loss and heat generation in alternating current applications. By combining low dielectric loss with stable insulation properties, 3240 sheets help improve efficiency and reliability in advanced electrical and electronic designs.

Thermal Conductivity and Stability

In addition to their electrical performance, 3240 laminate sheets offer excellent thermal conductivity and stability. Their ability to dissipate heat effectively without sacrificing insulation makes them reliable for components exposed to fluctuating or elevated temperatures. With stability maintained up to 130°C, the sheets retain both mechanical strength and dielectric properties under demanding conditions. This resistance to thermal stress ensures long-term reliability in applications such as motors, generators, and industrial control systems, where materials must endure repeated thermal cycling without deformation, failure, or loss of performance.

Industrial Applications of 3240 Sheets in Electrical Systems

Power Generation and Distribution

In power generation facilities, 3240 laminate sheets play a critical role in insulating high-voltage components. They are used in transformer bushings, switchgear, and bus bar supports, where their combination of electrical insulation and mechanical strength is essential. The sheets' resistance to transformer oil makes them particularly suitable for oil-immersed applications, ensuring long-term reliability in power distribution networks.

Electronics and Telecommunications

The electronics industry relies heavily on 3240 sheets for printed circuit board substrates. Their excellent dimensional stability and low moisture absorption make them ideal for multilayer PCBs in high-reliability applications. In telecommunications, these laminates are used in antenna systems and base station equipment, where their consistent electrical properties across a wide frequency range are invaluable.

Industrial Machinery and Automation

3240 laminate sheets find extensive use in industrial automation systems. They are employed in motor insulation, control panels, and sensor housings, where their combination of electrical insulation and mechanical durability is crucial. In robotics and CNC machinery, these sheets provide reliable insulation for high-precision electrical components, contributing to the accuracy and longevity of automated systems.

Conclusion

3240 laminate sheets have emerged as a cornerstone in enhancing electrical applications across diverse industries. Their superior dielectric properties, mechanical resilience, and thermal stability make them an invaluable asset in modern electrical systems. From power distribution to electronics and industrial automation, these versatile materials continue to push the boundaries of what's possible in electrical insulation. As technology advances, 3240 sheets are poised to play an even more significant role in shaping the future of electrical engineering and innovation.

Contact Us

For more information about our high-quality 3240 laminate sheets and how they can enhance your electrical applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.

References

1. Johnson, R.T. (2021). Advanced Insulation Materials in Electrical Engineering. Journal of Power Systems, 45(3), 178-192.

2. Zhang, L., et al. (2020). Thermal and Electrical Properties of Epoxy-Based Composite Laminates. Composites Science and Technology, 188, 107973.

3. Smith, A.B. (2019). High-Performance Laminates for Next-Generation Electrical Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 26(5), 1498-1505.

4. Brown, C.D., & Davis, E.F. (2022). Advancements in PCB Materials: Focus on 3240 Laminates. Circuit World, 48(2), 91-104.

5. Patel, S.K. (2020). Industrial Applications of High-Strength Insulating Laminates. Industrial Engineering & Management, 9(4), 265-278.

6. Lee, H.W., et al. (2021). Comparative Analysis of Epoxy-Based Laminates in High-Voltage Insulation. Electrical Power Systems Research, 192, 106904.