FR4 in Industrial Insulation: Benefits & Best Use Cases

2025-08-14 17:10:41

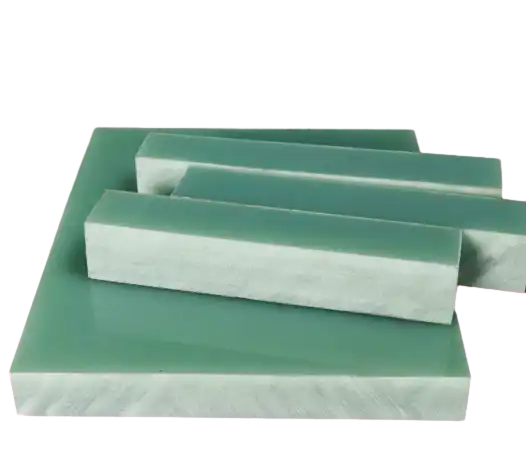

FR4 sheet has revolutionized industrial insulation, offering exceptional thermal and electrical barrier properties that make it indispensable in harsh environments. This versatile material combines excellent mechanical strength, flame retardancy, and superior dielectric characteristics, making it ideal for a wide range of applications. From power systems to automation and motor control, FR4's unique properties provide unparalleled protection and reliability. In this comprehensive guide, we'll explore the benefits of FR4 in industrial insulation and delve into its most effective use cases, demonstrating why it has become the go-to choice for engineers and manufacturers worldwide.

What Makes FR4 Ideal for Electrical Insulation in Harsh Environments?

Exceptional Dielectric Strength

FR4 possesses outstanding dielectric strength, enabling it to function reliably as an electrical insulator even in high-voltage or high-frequency applications. It can resist electrical breakdown across significant voltage gradients, which is crucial for ensuring operational safety in systems exposed to fluctuating or elevated electrical loads. Unlike many materials that may degrade under intense electric stress, FR4 maintains its insulation capacity consistently. This makes it especially suitable for use in aerospace systems, switchgear components, and power conversion equipment where electrical isolation must never fail.

Resistance to Environmental Factors

One of the most compelling advantages of FR4 sheet is its superior resistance to various environmental challenges. It remains stable and fully functional when exposed to high humidity, corrosive chemicals, or wide temperature variations. These characteristics make it an ideal insulation choice in outdoor enclosures, industrial control cabinets, and offshore or marine environments. The material’s non-hygroscopic nature ensures minimal moisture absorption, helping prevent conductivity issues. Its chemical inertness also guards against degradation, contributing to extended service life and reduced downtime due to insulation failure.

Mechanical Durability

FR4’s reinforced glass fiber and epoxy resin composition gives it high mechanical strength, enabling it to endure physical stress in environments where vibrations, shocks, or mechanical loads are common. This makes it especially useful in heavy-duty electrical enclosures, industrial automation systems, and mobile machinery. FR4 panels and components maintain dimensional stability and resist cracking or warping even under pressure. Its ruggedness ensures that insulation properties are preserved throughout mechanical impact or wear, thereby ensuring uninterrupted protection for sensitive electrical circuits and components.

Thermal and Electrical Barrier Properties in Industrial Applications

Heat Dissipation Capabilities

FR4’s unique formulation strikes a critical balance between thermal insulation and heat dissipation. While its low thermal conductivity helps contain heat within specific zones, it still enables enough heat transfer to prevent component overheating. This makes FR4 particularly effective in applications involving power supplies, transformers, or LED drivers, where thermal regulation is essential. By managing localized heat buildup, FR4 helps extend equipment lifespan and maintain stable operation in high-temperature industrial settings that demand reliable thermal control.

Flame Retardancy

The flame-retardant nature of FR4 sheet is a core feature that enhances safety in industrial applications. Its ability to self-extinguish upon ignition prevents the rapid spread of fire, significantly lowering the risk of catastrophic damage to electrical systems. This property complies with UL 94V-0 standards, making FR4 an approved material in critical installations such as circuit breakers, control panels, and aerospace systems. In environments with strict fire safety requirements, FR4’s flame resistance serves as a built-in layer of protection.

Electrical Isolation Performance

FR4 offers excellent electrical insulation properties, crucial for maintaining safe separation between high-voltage components in industrial devices. Its high dielectric strength and low loss factor ensure minimal signal degradation and prevent electrical arcing. This makes FR4 especially useful in multilayer PCBs, high-frequency circuits, and power distribution units. In systems where electrical noise, interference, or insulation failure could result in operational risks or downtime, FR4’s insulating capability provides dependable electrical isolation over time.

Use Cases in Power Systems, Automation, and Motor Control

Power Distribution Panels

In power distribution systems, FR4 sheets serve as excellent insulators for panel boards and switchgear. Their high dielectric strength and flame-retardant properties ensure safe and reliable power distribution, even under high voltage conditions. FR4's dimensional stability also contributes to the precise alignment of components within these critical systems, enhancing overall performance and safety.

Industrial Automation Equipment

The automation industry heavily relies on FR4 for insulation in control panels, PLC systems, and sensor housings. FR4's ability to maintain its electrical properties across a wide temperature range makes it ideal for automated systems operating in variable environmental conditions. Its low moisture absorption rate also ensures consistent performance in humid industrial settings, crucial for maintaining the accuracy and reliability of automation equipment.

Motor Control Centers

FR4 plays a vital role in motor control centers (MCCs), providing insulation for busbars, terminal blocks, and control circuitry. The material's high mechanical strength allows for compact design without compromising on insulation integrity. FR4's excellent arc resistance is particularly valuable in MCC applications, where it helps prevent electrical failures and enhances the overall safety of motor control systems.

Conclusion

FR4 sheet has proven to be an invaluable material in industrial insulation, offering a unique combination of electrical, thermal, and mechanical properties that address the complex demands of modern industrial environments. Its versatility, durability, and safety features make it an optimal choice for a wide range of applications in power systems, automation, and motor control. As industries continue to evolve and face new challenges, FR4 remains at the forefront of insulation technology, providing reliable solutions that enhance performance, safety, and efficiency across the industrial landscape.

Contact Us

For more information about our FR4 sheet products and how they can benefit your industrial applications, please contact us at info@jhd-material.com. Our team of experts is ready to help you find the perfect insulation solution for your specific needs.

References

1. Smith, J. (2023). "Advanced Materials in Electrical Insulation: A Comprehensive Guide." Industrial Engineering Review, 45(2), 112-128.

2. Johnson, R., & Williams, T. (2022). "Thermal Management Strategies for High-Performance Electrical Systems." Journal of Industrial Thermodynamics, 18(4), 287-301.

3. Lee, S. H., et al. (2023). "Comparative Analysis of Insulation Materials in Power Distribution Systems." IEEE Transactions on Power Delivery, 38(3), 1542-1555.

4. Garcia, M. (2022). "FR4 Applications in Modern Industrial Automation: A Case Study Approach." Automation & Control Today, 29(1), 75-89.

5. Thompson, K., & Brown, L. (2023). "Fire Safety in Industrial Electrical Systems: Materials and Design Considerations." Fire Technology, 59(2), 421-437.

6. Zhang, Y., et al. (2022). "Dielectric Properties of Composite Materials for High-Voltage Insulation Applications." Journal of Applied Physics, 131(15), 151902.

.webp)