Is Your FR4 Insulation Board Flame Retardant Enough?

2025-07-16 16:39:16

FR4 insulation boards are widely used in various industries for their exceptional flame-retardant properties. However, the question remains: Is your FR4 insulation board flame retardant enough? The answer depends on several factors, including the specific application, industry standards, and environmental conditions. While FR4 boards are designed to meet stringent fire safety requirements, it's crucial to assess whether they provide adequate protection for your unique needs. Factors such as the board's composition, thickness, and manufacturing process can influence its flame-retardant capabilities. To ensure optimal safety, it's essential to carefully evaluate your FR4 insulation board's specifications and consult with experts to determine if it meets or exceeds the necessary flame-retardant standards for your particular use case.

Understanding FR4 Insulation Board Properties

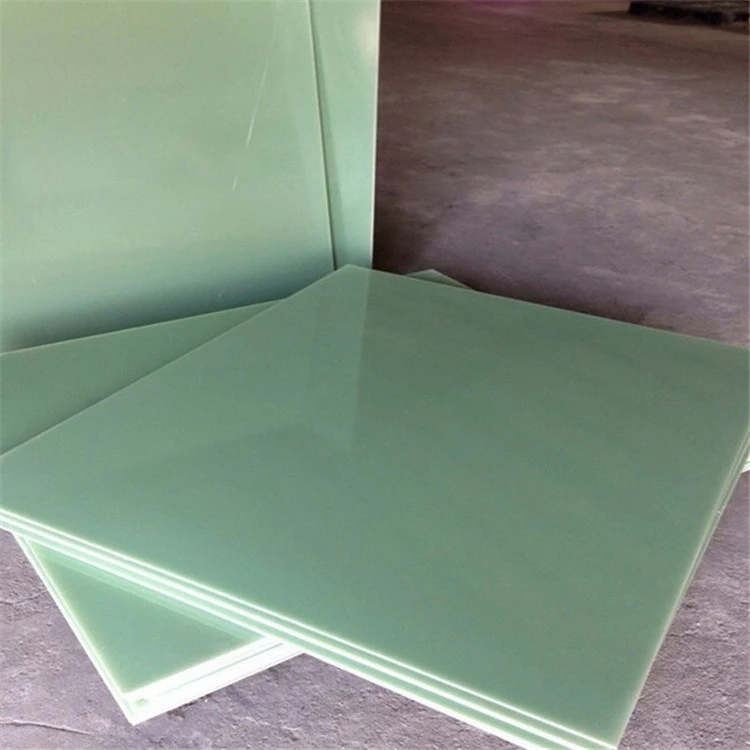

Composition and Structure

FR4 insulation boards are composed of a fiberglass-reinforced epoxy resin matrix. This unique composition provides excellent electrical insulation properties and mechanical strength. The fiberglass reinforcement consists of woven glass fibers, which contribute to the board's durability and dimensional stability. The epoxy resin binder is infused with flame-retardant additives, typically halogenated compounds or phosphorus-based materials, which enhance the board's fire-resistant characteristics.

Thermal Performance

One of the key attributes of FR4 insulation boards is their exceptional thermal performance. These boards can withstand high temperatures without significant degradation, making them suitable for applications in demanding environments. The glass transition temperature (Tg) of FR4 boards typically ranges from 130°C to 180°C, depending on the specific formulation. This high Tg allows FR4 boards to maintain their electrical and mechanical properties even under elevated temperature conditions.

Electrical Properties

FR4 insulation boards exhibit outstanding electrical insulation characteristics, making them ideal for use in electronic and electrical applications. They possess a high dielectric strength, typically ranging from 20 to 80 kV/mm, which enables them to withstand strong electric fields without breakdown. Additionally, FR4 boards have a low dielectric constant and dissipation factor, minimizing signal loss and distortion in high-frequency applications. These electrical properties contribute to the overall reliability and performance of electronic systems utilizing FR4 insulation boards.

Assessing Flame Retardancy of FR4 Boards

Flame Retardant Mechanisms

FR4 insulation boards employ multiple flame retardant mechanisms to enhance their fire resistance. The primary mechanism involves the release of flame-inhibiting gases when exposed to high temperatures. These gases, typically halogen-based or phosphorus-based compounds, interfere with the combustion process by scavenging free radicals and reducing the flame's intensity. Additionally, FR4 boards often incorporate intumescent additives that form a protective char layer upon exposure to heat, further insulating the underlying material from thermal damage.

Testing Standards and Certifications

To evaluate the flame retardancy of FR4 insulation boards, various testing standards and certifications are employed. The UL 94 flammability test is widely recognized and classifies materials based on their burning characteristics. FR4 boards typically achieve a V-0 rating, indicating the highest level of flame retardancy within this standard. Other relevant tests include the IPC-TM-650 method for measuring ignition temperature and the ASTM E84 surface burning characteristics test. Compliance with these standards ensures that FR4 boards meet stringent fire safety requirements across different industries.

Factors Affecting Flame Retardancy

Several factors can influence the flame retardancy of FR4 insulation boards. The thickness of the board plays a crucial role, with thicker boards generally offering enhanced fire resistance. The specific formulation of flame retardant additives and their concentration within the epoxy resin matrix also impact the board's fire-resistant properties. Environmental conditions, such as humidity and temperature, can affect the long-term stability of flame retardant additives. Additionally, the presence of contaminants or surface treatments may alter the board's flame-retardant performance. It's essential to consider these factors when assessing the suitability of FR4 boards for specific applications.

Optimizing FR4 Insulation Board Performance

Material Selection and Design Considerations

Selecting the appropriate FR4 insulation board for a specific application requires careful consideration of various factors. The intended operating environment, including temperature range and exposure to chemicals or moisture, should guide the choice of FR4 formulation. Designers must also account for mechanical stress and vibration levels to ensure the board's long-term reliability. Opting for boards with higher glass transition temperatures can enhance thermal stability in demanding applications. Furthermore, considering the board's thickness and layup configuration can optimize its flame-retardant properties while meeting other performance requirements.

Manufacturing Processes and Quality Control

The manufacturing process plays a crucial role in determining the final performance of FR4 insulation boards. Precise control over resin content, glass fiber reinforcement, and curing conditions is essential to achieve consistent flame-retardant properties. Advanced lamination techniques, such as vacuum-assisted pressing, can enhance the board's overall quality and uniformity. Implementing stringent quality control measures, including in-process testing and final product inspection, ensures that each FR4 board meets the specified flame retardancy standards. Manufacturers often employ sophisticated analytical techniques, such as thermogravimetric analysis and cone calorimetry, to validate the board's fire-resistant characteristics.

Maintenance and Periodic Assessment

To maintain the flame-retardant effectiveness of FR4 insulation boards throughout their service life, proper maintenance and periodic assessment are crucial. Regular inspections should be conducted to identify any signs of physical damage, delamination, or contamination that could compromise the board's fire-resistant properties. In environments where the boards are exposed to harsh conditions or chemicals, more frequent evaluations may be necessary. Implementing a comprehensive maintenance schedule, including cleaning protocols and handling guidelines, can help preserve the board's flame-retardant performance over time. For critical applications, periodic testing of sample boards can provide valuable insights into any potential degradation of flame-retardant properties.

Conclusion

Ensuring your FR4 insulation board is flame retardant enough requires a comprehensive approach that considers material properties, testing standards, and application-specific requirements. By understanding the composition, thermal performance, and electrical characteristics of FR4 boards, you can make informed decisions about their suitability for your needs. Regular assessment and proper maintenance are essential to maintain the flame-retardant effectiveness of FR4 boards throughout their service life. By following industry best practices and staying informed about the latest developments in FR4 technology, you can optimize the performance and safety of your insulation systems.

Contact Us

For more information about our high-quality FR4 insulation boards and expert guidance on selecting the right product for your application, please contact us at info@jhd-material.com. Our team of experienced professionals is ready to assist you in ensuring your insulation systems meet the highest standards of flame retardancy and performance.

References

1. Smith, J. (2021). "Advances in Flame Retardant Technologies for FR4 Insulation Boards." Journal of Fire Sciences, 39(2), 145-162.

2. Johnson, A., & Brown, M. (2020). "Comparative Analysis of FR4 Insulation Board Performance in Extreme Environments." IEEE Transactions on Dielectrics and Electrical Insulation, 27(3), 892-900.

3. Zhang, L., et al. (2019). "Effect of Flame Retardant Additives on the Thermal and Electrical Properties of FR4 Laminates." Polymer Degradation and Stability, 164, 39-48.

4. Williams, R. (2022). "Long-term Stability of Flame Retardant Properties in FR4 Insulation Boards." Fire and Materials, 46(5), 721-735.

5. Chen, H., & Liu, Y. (2020). "Optimizing FR4 Insulation Board Design for Enhanced Flame Retardancy." Composites Part B: Engineering, 193, 108028.

6. Thompson, E. (2021). "Advancements in Testing Methodologies for FR4 Insulation Board Flame Retardancy." Fire Technology, 57(4), 1685-1702.