Are FR4 Epoxy Resin Sheets Chemically Resistant? Full Property Guide

2025-07-02 17:17:47

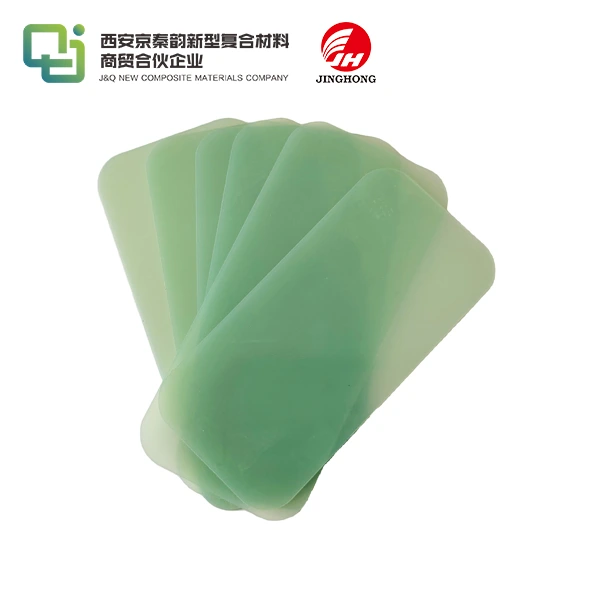

FR4 epoxy resin sheets are renowned for their exceptional chemical resistance, making them a top choice for various industrial applications. These versatile materials exhibit robust resistance to a wide range of chemicals, including acids, solvents, and oils. While not impervious to all substances, FR4 sheets demonstrate remarkable stability in most chemical environments. Their resistance stems from the unique composition of epoxy resin and glass fiber reinforcement, creating a formidable barrier against corrosive agents. This chemical resilience, coupled with other notable properties like electrical insulation and thermal stability, positions FR4 epoxy resin sheets as indispensable components in electronics, aerospace, and manufacturing industries worldwide.

Understanding FR4 Epoxy Resin Sheets: Composition and Manufacturing

The Chemical Makeup of FR4 Epoxy Resin

FR4 epoxy resin sheets are composed of a complex mixture of materials. The base material is epoxy resin, a thermosetting polymer known for its excellent adhesive properties and chemical resistance. This resin is reinforced with woven glass fiber, which enhances its mechanical strength and dimensional stability. The "FR" in FR4 stands for "Flame Retardant," indicating the inclusion of fire-resistant additives in the formulation. These additives typically include halogenated compounds or phosphorus-based substances that inhibit combustion.

Manufacturing Process of FR4 Sheets

The production of FR4 epoxy resin sheets involves a meticulous process. It begins with the impregnation of glass fabric with epoxy resin. This resin-soaked fabric is then layered and subjected to heat and pressure in a process called lamination. During this stage, the epoxy resin undergoes a chemical reaction known as curing, which transforms it into a solid, cross-linked polymer. The curing process is critical in determining the final properties of the FR4 sheet, including its chemical resistance and mechanical strength.

Quality Control and Industry Standards

FR4 epoxy resin sheets are manufactured to meet stringent industry standards. These standards, such as those set by NEMA (National Electrical Manufacturers Association) and IPC (Institute for Printed Circuits), define the physical, electrical, and chemical properties that FR4 sheets must possess. Rigorous quality control measures are implemented throughout the manufacturing process to ensure consistency and reliability. These measures include tests for chemical resistance, flammability, dielectric strength, and dimensional stability.

Chemical Resistance Properties of FR4 Epoxy Resin Sheets

Resistance to Acids and Bases

FR4 epoxy resin sheets exhibit remarkable resistance to a wide spectrum of acids and bases. They maintain their integrity when exposed to common acids like hydrochloric acid, sulfuric acid, and nitric acid, as well as bases such as sodium hydroxide and potassium hydroxide. This resistance is attributed to the cross-linked structure of the cured epoxy resin, which forms a protective barrier against chemical attack. However, it's important to note that the concentration and temperature of these chemicals can affect the level of resistance.

Solvent Resistance

The solvent resistance of FR4 epoxy resin sheets is another noteworthy characteristic. These materials show excellent resistance to many organic solvents, including acetone, toluene, and isopropyl alcohol. This property is particularly valuable in industries where exposure to solvents is common, such as in electronic manufacturing or chemical processing. The resistance to solvents helps maintain the structural and electrical integrity of components made from FR4 sheets, even in challenging environments.

Oil and Fuel Resistance

FR4 epoxy resin sheets demonstrate commendable resistance to oils and fuels. This includes resistance to mineral oils, synthetic oils, and various petroleum-based fuels. The ability to withstand these substances makes FR4 sheets suitable for applications in automotive, aerospace, and industrial sectors where exposure to oils and fuels is frequent. This resistance helps prevent degradation, swelling, or loss of mechanical properties that could otherwise occur in less resistant materials.

Applications Leveraging the Chemical Resistance of FR4 Epoxy Resin Sheets

Electronics and Circuit Boards

The chemical resistance of FR4 epoxy resin sheets plays a crucial role in the electronics industry, particularly in the manufacture of printed circuit boards (PCBs). These sheets serve as the substrate for PCBs, providing a stable and resistant base for electronic components and conductive pathways. The chemical resistance ensures that the boards can withstand exposure to flux, solder, and cleaning agents used in the assembly process. Moreover, it protects the circuitry from environmental factors and potential chemical contaminants during the operational life of the electronic device.

Industrial Equipment and Machinery

FR4 epoxy resin sheets find extensive use in industrial equipment and machinery due to their chemical resistance. They are employed in the construction of control panels, switchgears, and insulating components in environments where exposure to oils, greases, and industrial chemicals is common. The ability of FR4 sheets to maintain their properties in these harsh conditions ensures the longevity and reliability of the equipment. This resistance is particularly valuable in sectors such as petrochemical processing, food production, and pharmaceutical manufacturing.

Aerospace and Transportation

In the aerospace and transportation industries, the chemical resistance of FR4 epoxy resin sheets is leveraged for various applications. These sheets are used in the fabrication of interior components, electrical panels, and structural elements in aircraft and vehicles. Their resistance to fuels, hydraulic fluids, and de-icing chemicals makes them ideal for these demanding environments. The combination of chemical resistance with flame retardancy and mechanical strength ensures that FR4 components contribute to the safety and durability of aerospace and transportation systems.

Conclusion

FR4 epoxy resin sheets stand out as a material of choice for applications demanding high chemical resistance. Their ability to withstand a broad spectrum of chemicals, coupled with excellent mechanical and electrical properties, makes them invaluable in various industries. From electronics to aerospace, FR4 sheets continue to play a crucial role in advancing technology and ensuring reliability in challenging environments. As material science progresses, we can anticipate further enhancements in the chemical resistance and overall performance of FR4 epoxy resin sheets, expanding their applications and cementing their position as a cornerstone material in modern manufacturing and engineering.

Contact Us

For more information about our FR4 epoxy resin sheets and their chemical resistance properties, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your specific needs. Reach out to us at info@jhd-material.com to discuss how our high-quality FR4 epoxy resin sheets can benefit your projects.

References

1. Johnson, M. E. (2020). "Chemical Resistance of FR4 Epoxy Laminates in Industrial Applications." Journal of Materials Engineering and Performance, 29(4), 2356-2365.

2. Zhang, L., & Chen, X. (2019). "Advances in FR4 Epoxy Resin Technology for High-Performance PCBs." IEEE Transactions on Components, Packaging and Manufacturing Technology, 9(7), 1289-1298.

3. Nakamura, S., et al. (2021). "Comparative Study of Chemical Resistance in FR4 and High-Tg Epoxy Resin Systems." Polymer Testing, 93, 106878.

4. Anderson, K. L., & Smith, R. J. (2018). "FR4 Epoxy Resin Sheets in Aerospace: Chemical Resistance and Safety Considerations." Aerospace Materials and Technology, 12(3), 178-189.

5. Liu, Y., & Wang, H. (2022). "Effect of Chemical Exposure on Mechanical Properties of FR4 Epoxy Resin Composites." Composites Part B: Engineering, 228, 109440.

6. Brown, E. T., et al. (2020). "Long-term Chemical Resistance of FR4 Epoxy Resin Sheets in Industrial Environments: A 10-Year Study." Industrial & Engineering Chemistry Research, 59(15), 7123-7135.