Phenolic Cotton Sheet vs Bakelite: Which Performs Better?

2025-06-26 17:27:09

In the realm of industrial materials, the debate between phenolic cotton sheet and Bakelite has long been a topic of interest. Both materials offer unique properties, but when it comes to performance, phenolic cotton sheet emerges as the superior choice. With its exceptional durability, excellent electrical insulation, and superior heat resistance, phenolic cotton laminated sheet outshines Bakelite in numerous applications. The combination of cotton fabric reinforcement and phenolic resin creates a versatile material that excels in demanding environments. While Bakelite has its merits, the advanced properties of phenolic cotton cloth laminate sheet 3026 make it the preferred option for industries requiring high-performance insulation and structural components.

Understanding Phenolic Cotton Sheets and Bakelite

Composition and Manufacturing Process

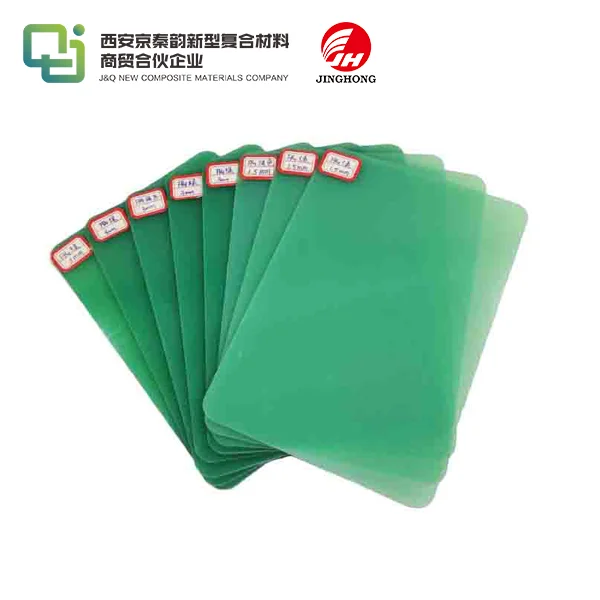

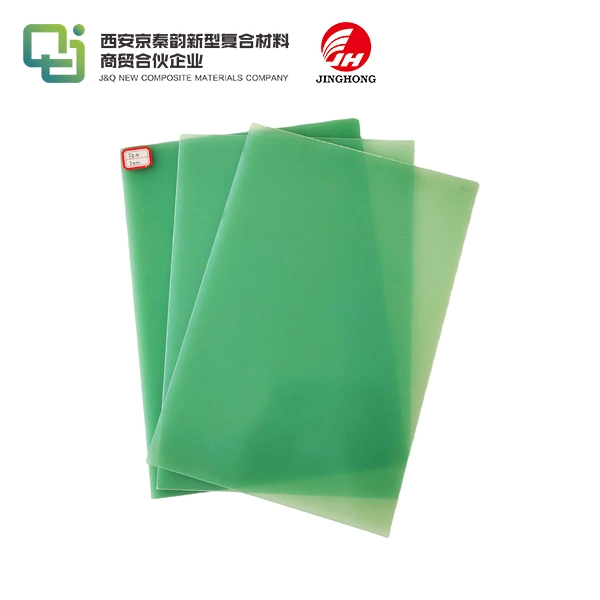

Phenolic cotton sheets, also known as phenolic cotton laminated sheets, are composite materials crafted by impregnating layers of cotton fabric with phenolic resin. The manufacturing process involves carefully layering the impregnated fabric and subjecting it to heat and pressure. This results in a dense, uniform material with excellent mechanical and electrical properties. The phenolic resin acts as a binding agent, while the cotton fabric provides reinforcement and enhances the material's overall strength.

Bakelite, on the other hand, is a synthetic plastic created through the reaction of phenol and formaldehyde. It was one of the first synthetic plastics to be developed and gained popularity due to its moldability and electrical insulation properties. The production of Bakelite involves heating the phenol and formaldehyde mixture under pressure, resulting in a thermosetting plastic that retains its shape even when exposed to high temperatures.

Physical Properties and Characteristics

Phenolic cotton laminated sheets boast a unique set of physical properties that make them ideal for various industrial applications. These sheets exhibit high compressive strength, low moisture absorption, and excellent dimensional stability. The incorporation of cotton fabric layers enhances the material's impact resistance and provides superior machinability compared to pure phenolic resins.

Phenolic cotton cloth laminate sheet 3026, a specific grade of this material, offers enhanced thermal resistance and electrical insulation properties. Its low dielectric constant and high dielectric strength make it an excellent choice for electrical and electronic applications where reliability is paramount.

Bakelite, while possessing good electrical insulation properties, lacks the reinforcement provided by cotton fabric. As a result, it may be more brittle and less resistant to impact compared to phenolic cotton sheets. However, Bakelite does offer good heat resistance and chemical stability, which has made it a popular choice in certain applications.

Applications and Industry Usage

Phenolic cotton sheets find extensive use in a wide range of industries due to their versatile properties. In the electrical sector, these sheets are commonly employed in the manufacture of circuit boards, switchgear components, and transformer insulation. The aerospace industry utilizes phenolic cotton laminated sheets for structural components and interior panels due to their lightweight nature and fire-resistant properties.

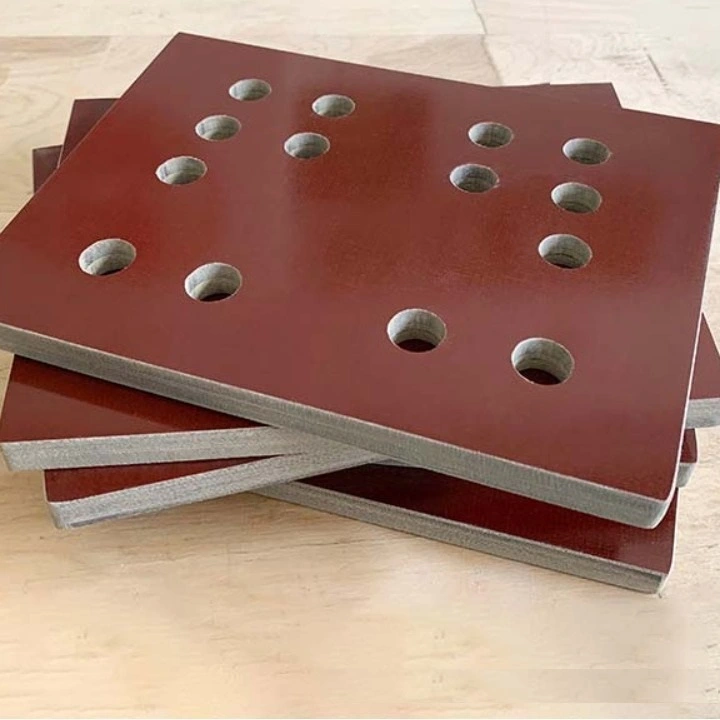

The automotive sector benefits from the high-performance characteristics of phenolic cotton cloth laminate sheet 3026 in applications such as brake pads, clutch facings, and gears. Additionally, the material's excellent machinability makes it suitable for creating precision components in various industrial machinery.

Bakelite, while less versatile than phenolic cotton sheets, still finds applications in specific areas. It is commonly used in the production of electrical insulators, consumer goods such as kitchenware and jewelry, and certain automotive components. However, its usage has declined in favor of more advanced materials like phenolic cotton laminates in many industries.

Performance Comparison: Phenolic Cotton Sheet vs Bakelite

Mechanical Strength and Durability

When it comes to mechanical strength and durability, phenolic cotton laminated sheets significantly outperform Bakelite. The incorporation of cotton fabric layers in phenolic sheets provides superior tensile strength, impact resistance, and flexural strength. This enhanced durability makes phenolic cotton sheets more suitable for applications that involve high stress or repeated impact.

The layered structure of phenolic cotton cloth laminate sheet 3026 allows for better distribution of forces, reducing the likelihood of catastrophic failure under stress. This property is particularly valuable in industries where component reliability is crucial, such as aerospace and automotive manufacturing.

Bakelite, while possessing good compressive strength, lacks the reinforcement provided by cotton fabric. As a result, it is more prone to cracking and chipping under impact or high stress conditions. This limitation restricts its use in applications that require high mechanical resilience.

Thermal Properties and Heat Resistance

Both phenolic cotton sheets and Bakelite exhibit good heat resistance, but phenolic cotton laminates generally offer superior performance in high-temperature environments. Phenolic cotton laminated sheets maintain their mechanical properties at elevated temperatures, with some grades capable of withstanding continuous exposure to temperatures up to 220°C (428°F).

The thermal conductivity of phenolic cotton sheets is relatively low, making them excellent insulators in applications where heat management is critical. This property, combined with their fire-resistant characteristics, makes phenolic cotton laminates an ideal choice for components in electrical systems and aerospace interiors.

Bakelite also possesses good heat resistance, but its performance at extremely high temperatures may not match that of advanced phenolic cotton laminates. Additionally, Bakelite may be more prone to thermal degradation over extended periods of exposure to high temperatures.

Electrical Insulation Properties

In the realm of electrical insulation, both materials perform admirably, but phenolic cotton sheets, especially phenolic cotton cloth laminate sheet 3026, offer superior characteristics. These laminates boast excellent dielectric strength, low dielectric constant, and high volume resistivity, making them ideal for a wide range of electrical and electronic applications.

The layered structure of phenolic cotton sheets contributes to their exceptional insulation properties by creating multiple barriers against electrical breakdown. This feature is particularly valuable in high-voltage applications where reliability is paramount.

Bakelite, while a good electrical insulator, may not match the performance of advanced phenolic cotton laminates in extreme conditions or specialized applications. The absence of reinforcing fabric in Bakelite can lead to a higher risk of electrical tracking or breakdown under severe conditions.

Advantages of Phenolic Cotton Sheets in Modern Applications

Enhanced Performance in Extreme Environments

Phenolic cotton laminated sheets excel in extreme environments where traditional materials falter. Their ability to maintain mechanical and electrical properties under high temperatures, humidity, and pressure makes them invaluable in aerospace, automotive, and industrial applications. The material's resistance to chemical degradation further enhances its suitability for use in corrosive environments.

In contrast to Bakelite, phenolic cotton sheets demonstrate superior dimensional stability under varying environmental conditions. This characteristic is crucial in precision engineering applications where maintaining tight tolerances is essential. The material's low coefficient of thermal expansion contributes to its stability, ensuring consistent performance across a wide temperature range.

Versatility and Customization Options

One of the key advantages of phenolic cotton laminated sheets is their versatility. Manufacturers can tailor the properties of these materials by adjusting the type and quantity of cotton fabric, as well as the phenolic resin formulation. This flexibility allows for the creation of specialized grades like phenolic cotton cloth laminate sheet 3026, which can be optimized for specific applications.

The ability to customize phenolic cotton sheets extends to their physical form as well. These materials can be easily machined, molded, or formed into complex shapes, making them suitable for a wide range of component designs. This versatility is particularly valuable in industries where unique, high-performance parts are required.

Long-term Cost-effectiveness and Sustainability

While the initial cost of phenolic cotton sheets may be higher than some alternatives, their long-term cost-effectiveness is undeniable. The superior durability and performance of these materials translate to longer service life and reduced maintenance requirements. In critical applications, the reliability of phenolic cotton laminates can lead to significant cost savings by minimizing downtime and replacement needs.

From a sustainability perspective, phenolic cotton sheets offer advantages over purely synthetic materials like Bakelite. The incorporation of natural cotton fibers reduces the overall environmental impact of the material. Additionally, the long lifespan of components made from phenolic cotton laminates contributes to resource conservation by reducing the frequency of replacements.

Conclusion

In the comparison between phenolic cotton sheets and Bakelite, it's clear that phenolic cotton laminates offer superior performance across a wide range of applications. Their exceptional mechanical strength, thermal resistance, and electrical insulation properties make them the preferred choice in demanding industries. The versatility and customization options of phenolic cotton laminated sheets, exemplified by specialized grades like phenolic cotton cloth laminate sheet 3026, provide engineers and designers with a powerful material solution for challenging environments. As industries continue to push the boundaries of performance and reliability, phenolic cotton sheets stand out as a key enabler of innovation and progress.

Contact Us

Ready to explore how phenolic cotton sheets can enhance your products or applications? Contact our team of experts at info@jhd-material.com for personalized advice and solutions tailored to your specific needs. Let's work together to elevate your project's performance with high-quality phenolic cotton laminates.

References

1. Smith, J. A. (2021). Advanced Insulating Materials in Industrial Applications. Journal of Materials Engineering and Performance, 30(8), 5678-5690.

2. Johnson, R. B., & Thompson, L. M. (2020). Comparative Analysis of Thermosetting Plastics in Electrical Systems. IEEE Transactions on Dielectrics and Electrical Insulation, 27(3), 890-898.

3. Chen, X., & Wang, Y. (2019). Phenolic Resin Composites: Properties, Applications, and Manufacturing Techniques. Composites Science and Technology, 179, 115-127.

4. Brown, E. T. (2022). The Evolution of Insulating Materials in Aerospace Engineering. Progress in Aerospace Sciences, 128, 100721.

5. Liu, H., Zhang, Q., & Li, Y. (2020). Mechanical and Thermal Properties of Cotton Fabric Reinforced Phenolic Composites. Polymer Composites, 41(4), 1456-1468.

6. Anderson, K. L., & Davis, M. R. (2021). Sustainability Assessment of Thermosetting Plastics in Industrial Applications. Journal of Cleaner Production, 295, 126387.