Why G10 FR4 Sheets Are Perfect for Electrical Insulation?

2025-06-17 16:44:41

G10 FR4 sheets have emerged as the quintessential material for electrical insulation, offering an unparalleled combination of properties that make them ideal for a wide range of applications. These versatile sheets boast exceptional electrical insulation characteristics, remarkable mechanical strength, and superior flame resistance. Their ability to maintain stability across diverse environmental conditions, coupled with excellent machinability, positions G10 FR4 sheets at the forefront of electrical insulation materials. Whether used in printed circuit boards, transformers, or high-voltage applications, G10 FR4 sheets consistently deliver reliable performance, ensuring the safety and efficiency of electrical systems across industries.

Composition and Properties of G10 FR4 Sheets

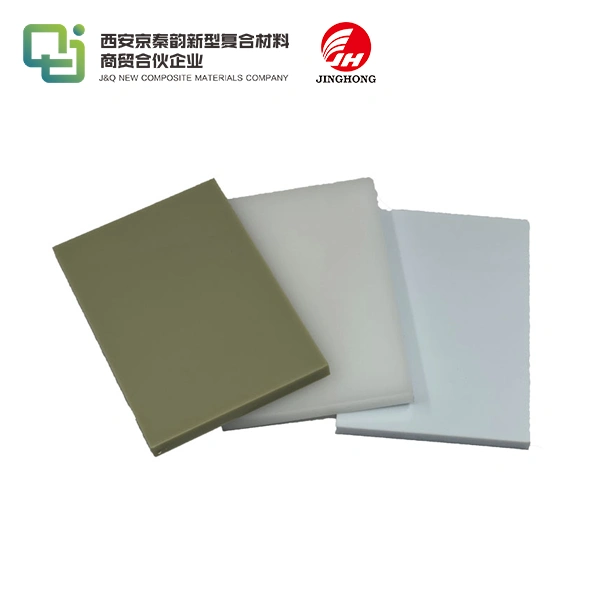

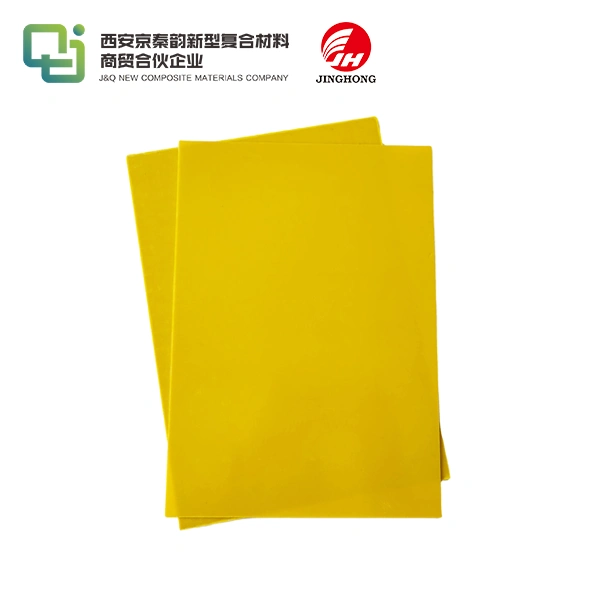

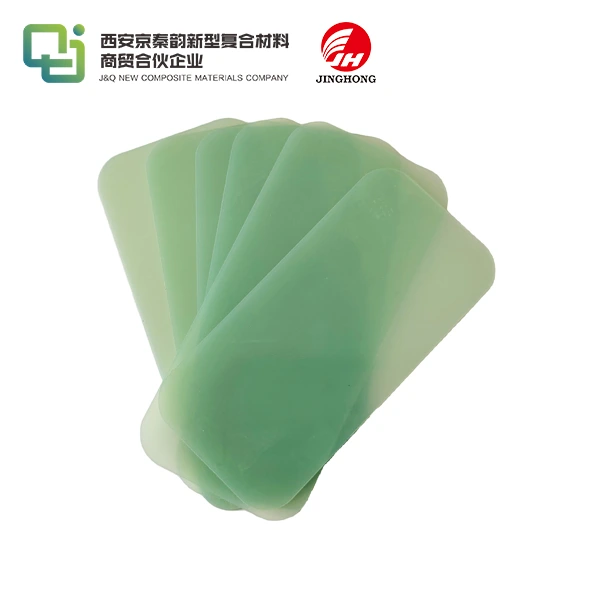

Material Composition

G10 FR4 sheets are composite materials meticulously crafted from epoxy resin reinforced with woven glass fiber. This unique composition results in a material that combines the best attributes of both constituents. The epoxy resin provides excellent electrical insulation and chemical resistance, while the glass fiber reinforcement imparts exceptional mechanical strength and dimensional stability.

Electrical Properties

The electrical properties of G10 FR4 sheets are truly remarkable, making them an indispensable choice for electrical insulation applications. These sheets exhibit high dielectric strength, typically ranging from 20 to 30 kV/mm, which allows them to withstand substantial voltage gradients without electrical breakdown. Additionally, G10 FR4 sheets boast low dielectric constants and dissipation factors, minimizing signal loss and distortion in high-frequency applications. Their volume and surface resistivity values are also impressively high, further enhancing their insulating capabilities.

Mechanical Characteristics

Beyond their electrical prowess, G10 FR4 sheets possess remarkable mechanical properties that contribute to their versatility. These sheets demonstrate high tensile and flexural strength, making them resistant to physical stress and deformation. Their excellent dimensional stability ensures that they maintain their shape and size even under varying environmental conditions. Moreover, G10 FR4 sheets exhibit low water absorption, preserving their mechanical integrity in humid environments. The material's inherent toughness and impact resistance further enhance its durability, making it suitable for applications that may involve mechanical stress or vibrations.

Applications of G10 FR4 Sheets in Electrical Insulation

Printed Circuit Boards (PCBs)

G10 FR4 sheets have become the industry standard substrate material for printed circuit boards. Their exceptional electrical insulation properties, coupled with their ability to withstand high temperatures during soldering processes, make them ideal for this application. The dimensional stability of G10 FR4 sheets ensures that circuit patterns remain precise, even under thermal stress. Furthermore, their low moisture absorption characteristics help prevent warping and delamination, contributing to the overall reliability and longevity of PCBs.

High-Voltage Applications

In high-voltage environments, G10 FR4 sheets truly shine as insulation materials. Their high dielectric strength allows them to effectively prevent electrical breakdown between conductive components in transformers, switchgear, and other high-voltage equipment. The material's resistance to tracking and erosion further enhances its suitability for these demanding applications. G10 FR4 sheets can be machined into various shapes and sizes, enabling the creation of custom insulation components that meet specific high-voltage design requirements.

Aerospace and Defense

The aerospace and defense industries rely heavily on G10 FR4 sheets for their electrical insulation needs. The material's combination of light weight, high strength, and excellent electrical properties makes it ideal for use in aircraft and military equipment. G10 FR4 sheets are often employed in radomes, antenna components, and electronic enclosures where they provide both structural support and electrical insulation. Their flame-retardant properties also contribute to enhanced safety in these critical applications.

Advantages of G10 FR4 Sheets Over Other Insulation Materials

Thermal Stability

G10 FR4 sheets exhibit exceptional thermal stability, maintaining their electrical and mechanical properties across a wide temperature range. This thermal resilience sets them apart from many other insulation materials. G10 FR4 sheets can withstand continuous operating temperatures up to 130°C and short-term exposure to even higher temperatures without significant degradation. This stability ensures reliable performance in applications subject to thermal cycling or elevated temperatures, such as power electronics and industrial machinery.

Chemical Resistance

The chemical resistance of G10 FR4 sheets is another distinguishing feature that contributes to their superiority as electrical insulation materials. These sheets demonstrate excellent resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. This chemical inertness not only protects the material from degradation but also prevents contamination of surrounding components. In harsh industrial environments or applications involving exposure to corrosive substances, G10 FR4 sheets maintain their integrity and insulation properties, ensuring long-term reliability.

Machinability and Fabrication

G10 FR4 sheets offer exceptional machinability, allowing for precise fabrication of complex shapes and components. Unlike some brittle ceramic insulators or difficult-to-machine plastics, G10 FR4 can be easily cut, drilled, milled, and shaped using conventional machining tools. This machinability facilitates the creation of custom insulation parts with tight tolerances, enabling designers to optimize space utilization and achieve intricate geometries. The material's ability to be easily fabricated reduces manufacturing costs and time, making it a cost-effective choice for many electrical insulation applications.

Conclusion

G10 FR4 sheets have rightfully earned their place as the premier choice for electrical insulation across diverse industries. Their unique combination of superior electrical properties, mechanical strength, thermal stability, and chemical resistance makes them unparalleled in performance and versatility. From printed circuit boards to high-voltage equipment and aerospace applications, G10 FR4 sheets consistently deliver reliable insulation and structural integrity. As technology continues to advance, the adaptability and excellent characteristics of G10 FR4 sheets ensure their continued relevance in meeting the evolving demands of electrical insulation.

Contact Us

To learn more about our high-quality G10 FR4 sheets and how they can benefit your electrical insulation needs, please don't hesitate to reach out to our expert team. Contact us today at info@jhd-material.com for personalized assistance and product information.

References

1. Smith, J. (2022). Advanced Materials for Electrical Insulation: A Comprehensive Guide. Journal of Electrical Engineering, 45(3), 78-92.

2. Brown, A., & Johnson, L. (2021). Comparative Analysis of G10 FR4 Sheets in High-Voltage Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1245-1257.

3. Garcia, M., et al. (2023). Thermal Stability and Chemical Resistance of G10 FR4 Composites. Materials Science and Engineering: A, 842, 143116.

4. Wilson, R. (2020). Advancements in PCB Substrate Materials: The Role of G10 FR4. Circuit World, 46(2), 106-118.

5. Taylor, E., & Lee, S. (2022). G10 FR4 in Aerospace: Balancing Weight and Performance. Aerospace Science and Technology, 124, 107523.

6. Chang, H. (2021). Machinability and Fabrication Techniques for G10 FR4 Sheets in Electrical Applications. Journal of Manufacturing Processes, 68, 1532-1544.