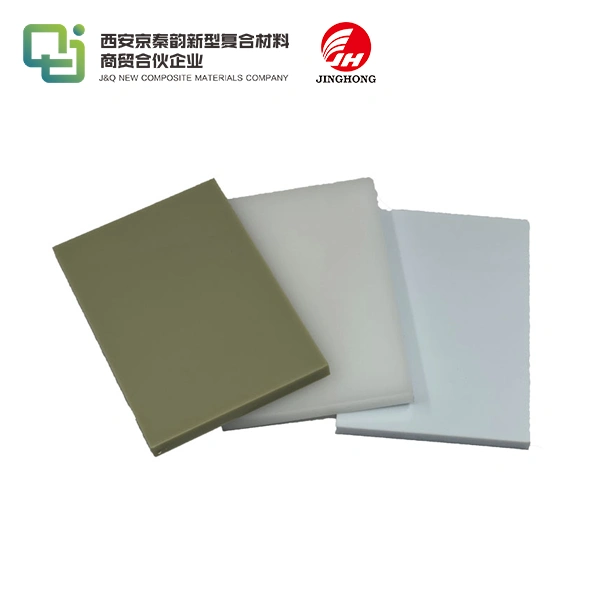

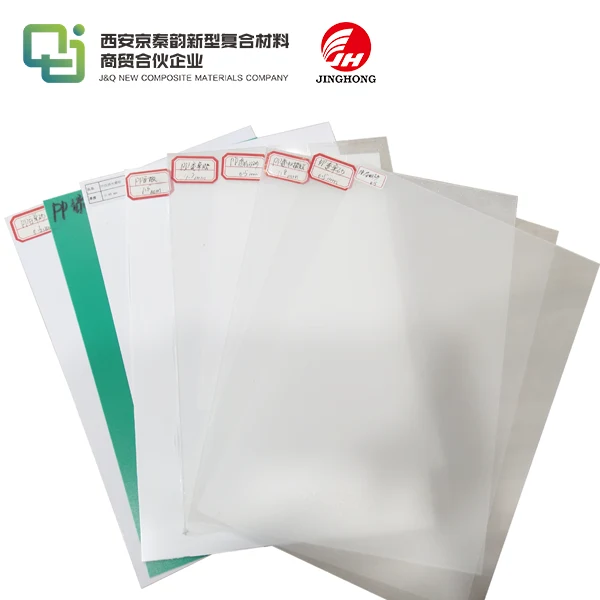

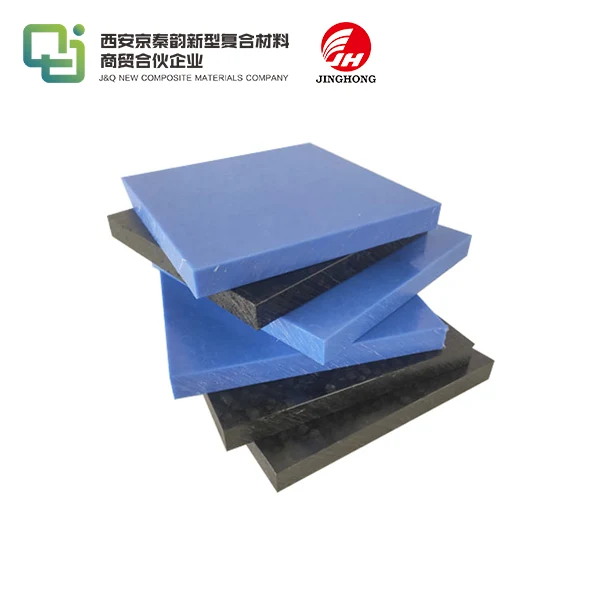

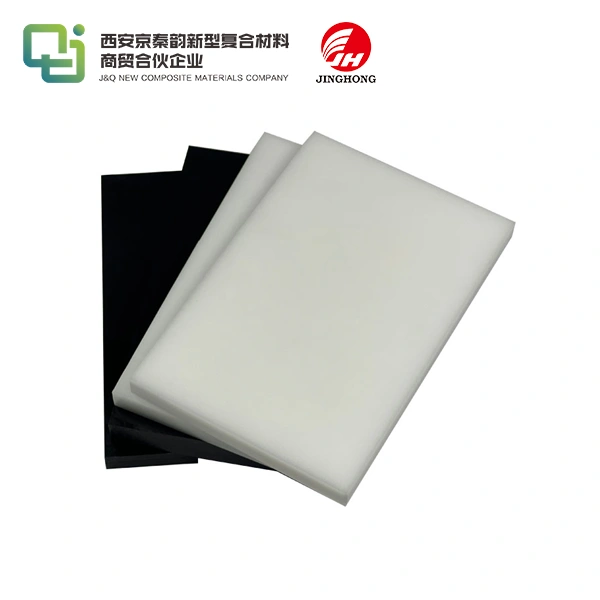

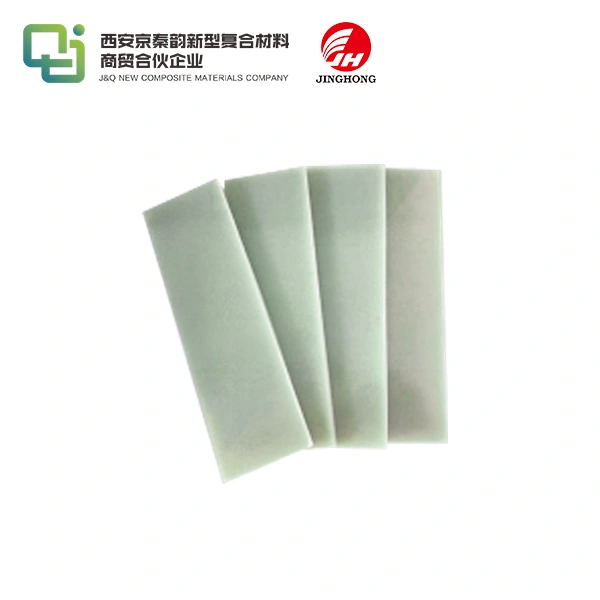

PP Plate Sheet

Material:Polypropylene

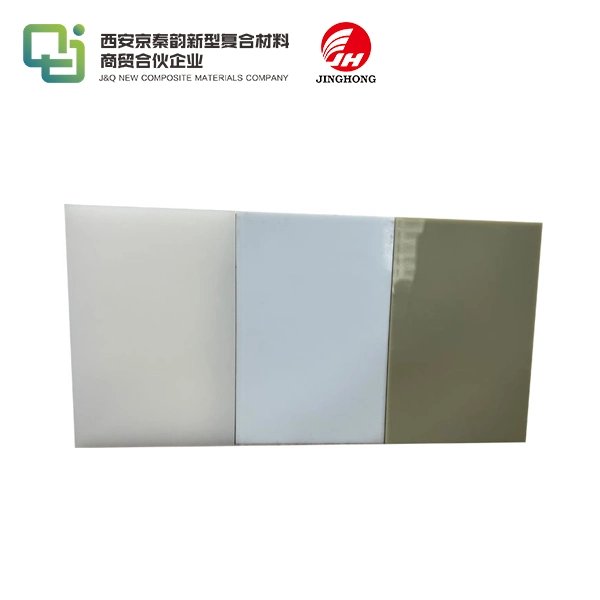

Color:White, Grey,Other colors can be customized

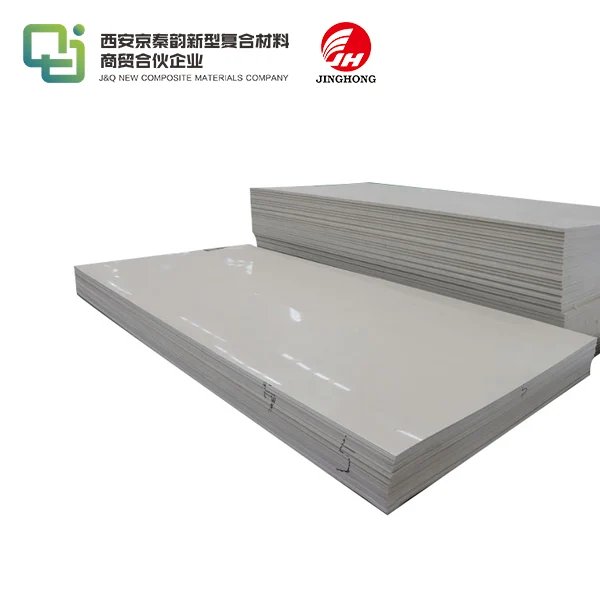

Size: 1000mm * 2000mm, 1220mm*2440mm, 1300mm*2000mm, 1500mm*3000mm, Other sizes can be customized

Packaging: Regular packing, Protect by Pallet

Transportation: Ocean, Land, Air

Payment:T/T

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Production Description

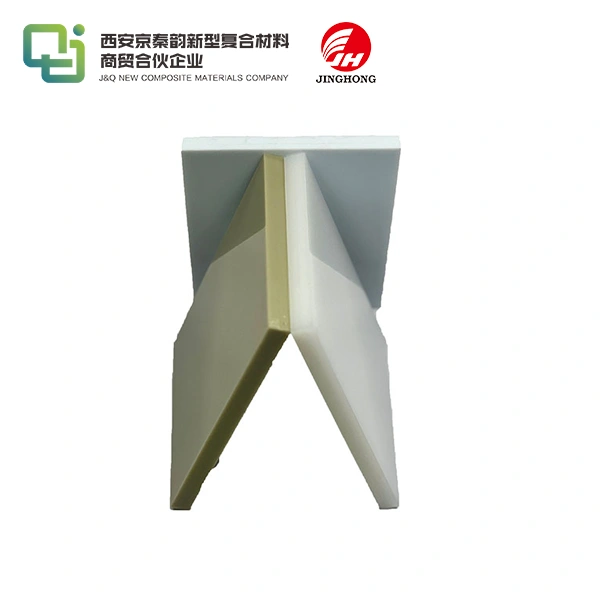

PP plate sheet also known as polypropylene (PP) board (PP pure board, modified PP board, reinforced PP board, PP electrode), is a semi crystalline material. It is harder than PE and has a higher melting point. Since homopolymer type PP is very brittle when the temperature is higher than 0 ℃, many commercial PP materials are irregular copolymers with 1~4% ethylene added or clamped copolymers with higher ethylene content.

PP extruded sheet has the characteristics of light weight, uniform thickness, smooth surface, good heat resistance, high mechanical strength, excellent chemical stability, electrical insulation and non-toxic. PP board is widely used in chemical containers, machinery, electronics, electrical appliances, food packaging, medicine, decoration, water treatment and other fields. The practical temperature of PP board can reach 100 ℃.

Application and Property

pp plastic sheet is Acid and alkali resistant equipment, electroplating equipment, solar photovoltaic equipment, environmental protection equipment, waste water and waste gas emission equipment, washing tower, dust-free room, semiconductor factory and related industrial equipment are also the preferred materials for manufacturing plastic water tanks, among which PP thick plates are widely used for stamping plates, punching bed pads, etc.

1. Advertising board;

2. Recycle boxes, including recycling boxes, vegetable and fruit packing boxes, suitcase, stationery boxes for various industries;

3. Industrial boards, including the outer packaging protection of wires and cables, the outer packaging protection of glass, steel plate, various articles, and the base plate, shelf, partition, bottom plate, etc;

4. The era of protecting building materials in construction with cardboard and plywood is gone forever. With the progress of the times and the improvement of taste, it is necessary to ensure the integrity of the decoration design before completion and use. Proper protection should be given to maintain the economy, safety and convenience of the operation. In addition, it is also necessary to protect the elevator and floor of the building before acceptance.

5. Electronic industry protection. Conductive packaging products are mainly used in the packaging of electronic components such as IC wafers, IC packaging, testing, TFT-LCD, photoelectric, etc. The purpose is to prevent other charged items from contacting them, causing spark damage to parts due to charge friction. In addition, there are conductive, anti-static plastic plates, turnover boxes, etc. PP board can be used in addition to the above products, but also used in washing machine backplane, refrigerator insulation, frozen food, medicine, sugar and wine and other packaging. PE hollow boards can also be produced by hollow board production lines to supply insulation room partitions required by urban construction and rural areas.

3mm polypropylene sheet is extruded from polypropylene. It has good chemical stability, heat resistance and electrical insulation. It can be used at 90-100 ℃. It is resistant to acid and alkali corrosion, non-toxic, and has good physical and mechanical properties. It is mainly used for food packaging, chemical containers and water treatment devices.

Technical Data for PP Sheet

|

No |

Test Items |

Unit |

Test Result |

Test Method |

|

1 |

Density |

g/cm³ |

0.913 |

GB/T 1033.1-2008 |

|

2 |

Tensile Strength |

MPa |

23.9 |

GB/T 1040.2/1B-2006 |

|

3 |

Bending Strength |

MPa |

37.1 |

GB/T 9341- 2008 |

|

4 |

Charpy Notched Impact Strength |

kJ/m² |

7.5 |

GB/T1043.1/1eA-2008 |

|

5 |

Vicat Heat Resistance (1kg,50℃/h) |

℃ |

142 |

GB/T 1633- 2000 |

|

6 |

Corrosion Resistance |

GB/T 12024-1989 |

||

|

6.1 |

40% NaOH Solution |

g/m² |

-0.37 |

|

|

6.2 |

40% HNO3 Solution |

g/m² |

-0.29 |

|

|

6.3 |

30% H2SO₄ Solution |

g/m² |

0.29 |

|

|

6.4 |

35% HCL Solution |

g/m² |

0.51 |

|

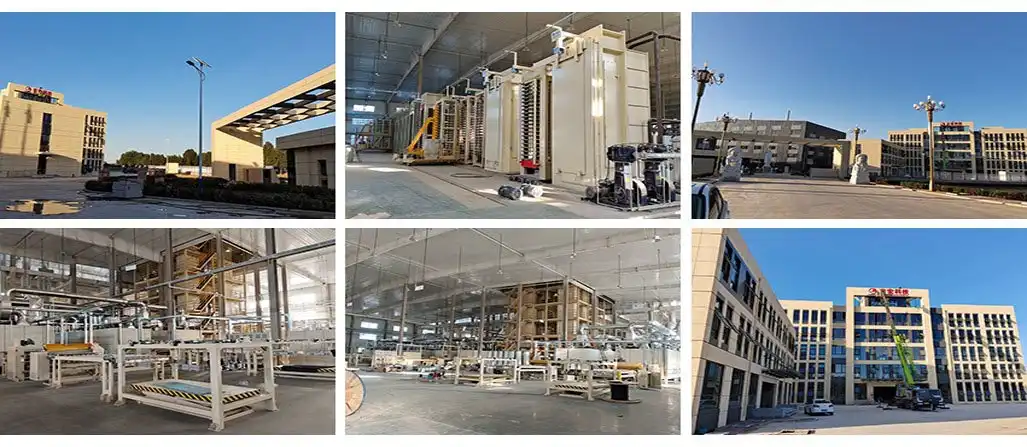

Factory

J&Q New Composite Material Group Co., Ltd is a national manufacturer of insulation materials and Epoxy Resin, Engineered Plastic. We have two factories. They are located in Heibei Province. One is Hongda Insulation Materials Factory was founded in 2000. Covering an area of 30000 square meters. Advanced process equipment, complete testing equipment. All of our equipment is fully automated production workshop. Mainly production is 3420 epoxy sheet grade B, Annual output of more than 13000 tons. it is the largest Grade B sheet manufacturer in China. And get honest and trustworthy unit and Consumer Satisfaction Trust Units and other honors issued by the government. we passed the ISO 9001quality management system certification.

The other is Hebei JingHong Electronic Technology Co., Ltd Covering an area of 66667 square meters. A total investment of 200 million CNY, annual output is 30,000 tons. JingHong is a new material company integrating scientific research, development, production, sales, and service. The main products are FR4 sheet,3240 epoxy sheet grade A, phenolic cotton sheet, Bakelite sheet, copper clad laminate, Epoxy Resin, and Engineered Plastic, which have strong insulation products development and production capacity. JingHong has the most advanced glue machine, thermal compressor, and a vertical upper glue machine specially equipped for FR4 sheets can ensure the best and most stable product quality.

We uphold quality first, integrity. Meanwhile, we have more than 20 years of experience in producing and selling insulating sheets and more than 10 years of export experience. Products are exported to Russia, Southeast Asia, the United States, Europe, and other countries, and the annual export volume accounts for 40% of the total export volume in China. What’s more, we have our own logistics company, so we can provide one-stop service. Look forward to long-team cooperation.

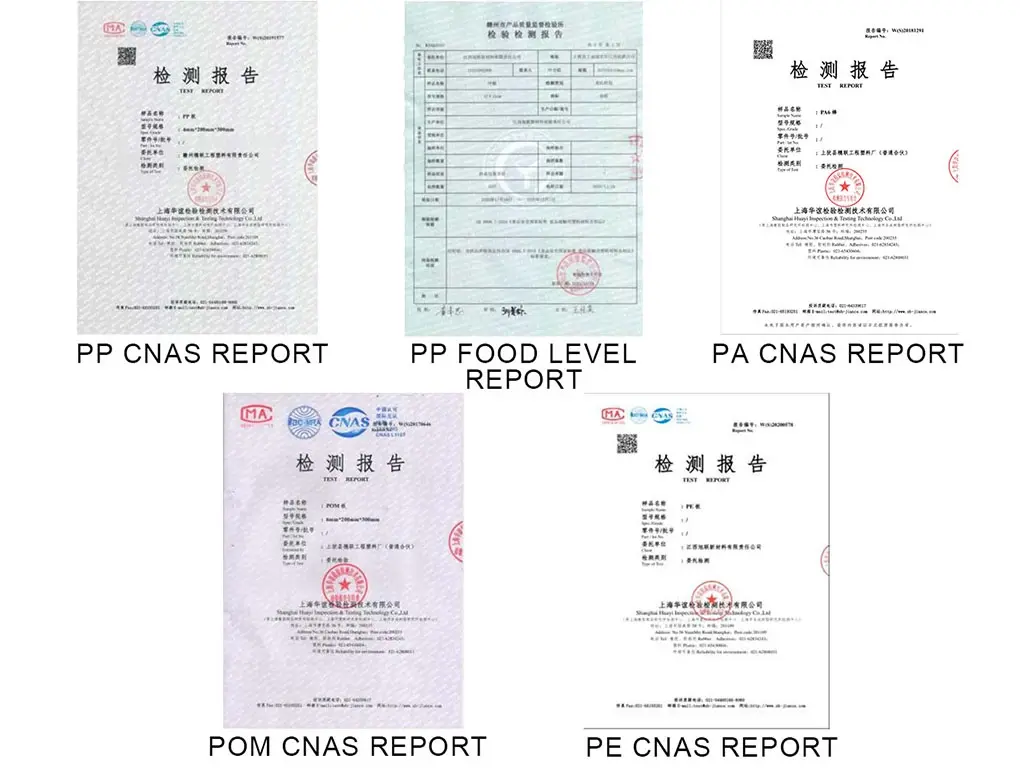

Certification

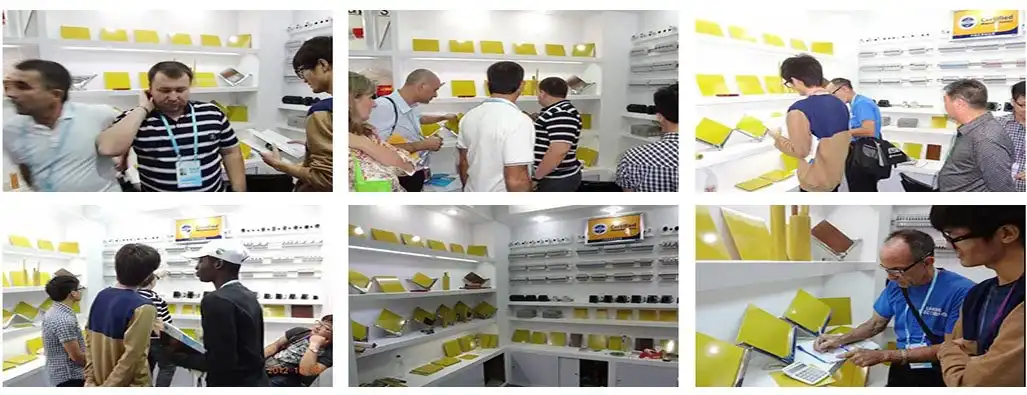

Exhibition

Package and Shipping

FAQ

Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q: Can you give me a discount price?

A: It is depending on the quantity.

Q: Which certification do you have?

A: Our factory has passed the certificate of ISO 9001 quality system certification;

The products have passed ROHS test.

Q: Can I get a free sample?

A: Free samples are available.

Q: How long is the delivery time?

A: Generally it is 10-15 days if the goods are in stock, or it is 5-10 days.

Q: What's the payment?

A:Payment<=1000USD, 100% in advance

Payment>=1000USD 30% TT advance, 70% TT before shipping.

Send Inquiry