How Aerospace Industries Benefit from Epoxy Glass Fiber Sheets?

2025-06-06 15:45:31

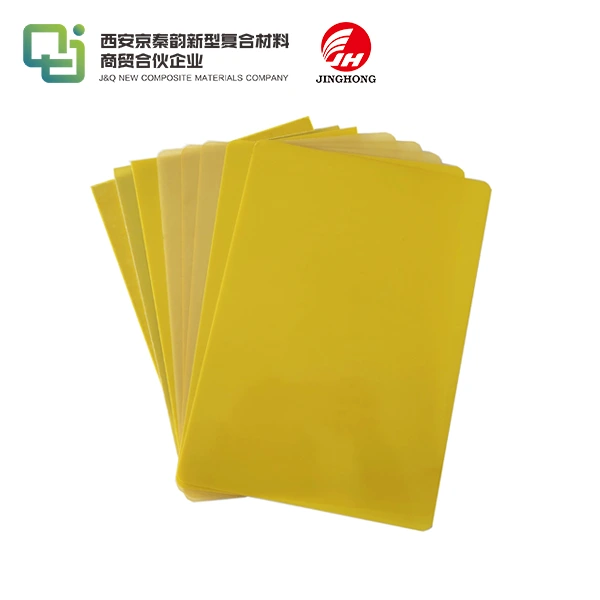

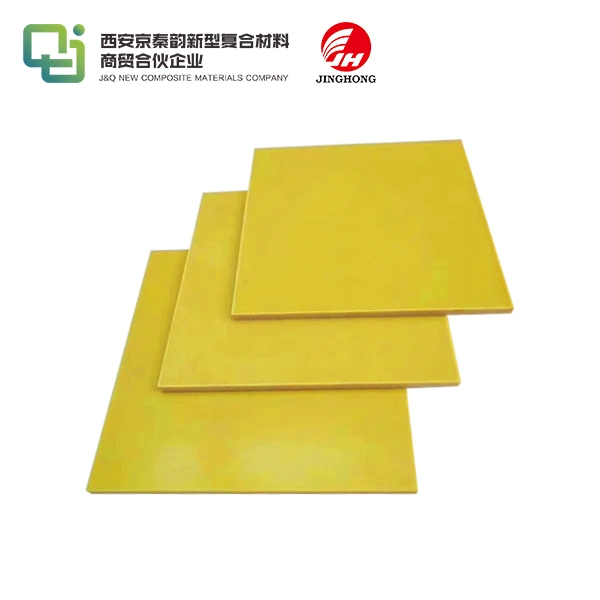

Aerospace industries reap substantial benefits from the utilization of epoxy glass fiber sheets, revolutionizing aircraft manufacturing and performance. These advanced composite materials offer a unique combination of high strength-to-weight ratio, excellent thermal and electrical insulation properties, and superior resistance to corrosion and fatigue. By incorporating epoxy glass fiber sheets into aircraft structures, aerospace manufacturers can significantly reduce overall weight, enhance fuel efficiency, and improve the durability and longevity of aircraft components. This translates to increased payload capacity, extended flight ranges, and reduced maintenance costs, ultimately leading to more cost-effective and environmentally friendly air travel. The versatility of epoxy glass fiber sheets allows for their application in various aircraft parts, from fuselage panels to interior components, contributing to the ongoing evolution of aerospace technology and design.

Properties and Characteristics of Epoxy Glass Fiber Sheets in Aerospace Applications

Exceptional Strength-to-Weight Ratio

Epoxy glass fiber sheets boast an impressive strength-to-weight ratio, making them an ideal material for aerospace applications. This property allows aircraft manufacturers to construct robust structures while minimizing overall weight. The high tensile strength of these sheets enables them to withstand the immense forces experienced during flight, including aerodynamic loads and vibrations. By replacing traditional metallic components with epoxy glass fiber sheets, aerospace engineers can achieve substantial weight reductions without compromising structural integrity. This weight savings directly translates to improved fuel efficiency and increased payload capacity, both of which are crucial factors in the competitive aviation industry.

Thermal and Electrical Insulation Properties

The thermal insulation capabilities of epoxy glass fiber sheets play a vital role in maintaining optimal operating temperatures within aircraft. These sheets effectively minimize heat transfer between the exterior and interior of the aircraft, contributing to passenger comfort and protecting sensitive equipment from extreme temperature fluctuations. Additionally, the electrical insulation properties of epoxy glass fiber sheets are invaluable in aerospace applications. They help prevent electromagnetic interference between various electronic systems onboard, ensuring the reliable operation of critical avionics and communication equipment. This insulation also enhances safety by reducing the risk of electrical arcing and short circuits, which could potentially lead to catastrophic failures in flight.

Resistance to Corrosion and Environmental Factors

Epoxy glass fiber sheets exhibit exceptional resistance to corrosion and environmental degradation, making them highly suitable for aerospace applications. Unlike many metallic materials, these sheets do not corrode when exposed to moisture, chemicals, or atmospheric pollutants. This resistance to corrosion is particularly beneficial for aircraft that operate in diverse environments, including coastal regions with high salt content in the air. The durability of epoxy glass fiber sheets translates to reduced maintenance requirements and extended service life for aircraft components. Furthermore, these sheets maintain their mechanical properties across a wide range of temperatures, ensuring consistent performance in the extreme conditions encountered during flight, from the frigid temperatures at high altitudes to the heat generated by air friction during high-speed travel.

Manufacturing Processes and Integration of Epoxy Glass Fiber Sheets in Aircraft Structures

Advanced Layup and Lamination Techniques

The manufacturing of aircraft components using epoxy glass fiber sheets involves sophisticated layup and lamination techniques. These processes are meticulously designed to optimize the orientation and arrangement of glass fibers within the epoxy matrix, maximizing strength and stiffness in specific directions based on anticipated loads. Computer-aided design (CAD) and finite element analysis (FEA) tools are employed to determine the optimal fiber orientation and layup sequence for each component. The layup process often involves the use of automated fiber placement (AFP) machines, which can precisely position and orient multiple layers of epoxy glass fiber sheets to create complex geometries. This level of precision ensures that each component achieves the desired mechanical properties while minimizing material waste and manufacturing time.

Curing and Post-Processing Methods

After the layup process, epoxy glass fiber sheets undergo curing to solidify the epoxy resin and create a rigid, high-performance composite structure. The curing process typically involves the application of heat and pressure in controlled environments, such as autoclaves or vacuum bagging systems. These methods ensure uniform curing throughout the component, minimizing internal stresses and voids that could compromise structural integrity. Post-curing treatments may be applied to further enhance the mechanical and thermal properties of the composite. Additionally, various finishing techniques, such as precision trimming, surface preparation, and painting, are employed to prepare the components for integration into the aircraft structure. These post-processing steps are crucial for achieving the required dimensional accuracy and surface quality necessary for aerodynamic performance and aesthetic appeal.

Quality Control and Non-Destructive Testing

Rigorous quality control measures and non-destructive testing (NDT) techniques are essential in the manufacturing and integration of epoxy glass fiber sheet components for aerospace applications. Advanced NDT methods, such as ultrasonic scanning, thermography, and X-ray computed tomography, are employed to detect internal defects, delaminations, or voids that may compromise the structural integrity of the composite. These inspection techniques allow manufacturers to identify and address potential issues before components are integrated into the aircraft structure. Furthermore, ongoing monitoring and inspection of composite structures during an aircraft's operational life are crucial for ensuring long-term safety and performance. The implementation of structural health monitoring systems, which utilize embedded sensors and advanced data analysis techniques, enables real-time assessment of the composite components' condition, facilitating predictive maintenance and enhancing overall aircraft reliability.

Future Trends and Innovations in Epoxy Glass Fiber Sheet Technology for Aerospace

Nanocomposite Enhancements

The integration of nanoparticles into epoxy glass fiber sheets represents a promising avenue for further enhancing their performance in aerospace applications. Researchers are exploring the incorporation of carbon nanotubes, graphene, and other nanomaterials to improve the mechanical, thermal, and electrical properties of these composites. These nanocomposite enhancements have the potential to significantly increase the strength and stiffness of epoxy glass fiber sheets while maintaining their lightweight characteristics. Additionally, the incorporation of nanoparticles can enhance the sheets' resistance to impact damage and improve their fatigue life, addressing some of the current limitations of composite materials in aerospace structures. The development of multifunctional nanocomposites that combine structural properties with additional functionalities, such as self-healing capabilities or integrated sensing, could revolutionize aircraft design and maintenance practices in the coming years.

Sustainable Manufacturing and Recyclability

As the aerospace industry increasingly focuses on sustainability, innovations in the manufacturing and recyclability of epoxy glass fiber sheets are gaining prominence. Researchers are developing bio-based epoxy resins derived from renewable resources, reducing the environmental impact of composite production. These sustainable alternatives aim to maintain or exceed the performance characteristics of traditional petroleum-based epoxy resins while offering improved end-of-life recyclability. Advanced recycling technologies, such as chemical recycling and fiber recovery processes, are being developed to address the challenges associated with recycling thermoset composites. These innovations not only contribute to reducing the carbon footprint of aircraft manufacturing but also align with circular economy principles, potentially leading to more efficient resource utilization and reduced waste in the aerospace industry.

Additive Manufacturing and 3D Printing Applications

The integration of additive manufacturing techniques with epoxy glass fiber sheet technology is opening new possibilities for aerospace component design and production. Advanced 3D printing methods, such as continuous fiber additive manufacturing (CFAM), allow for the creation of complex, optimized structures that were previously impossible or impractical to produce using traditional manufacturing methods. These additive manufacturing techniques enable the precise placement of fibers within the epoxy matrix, tailoring the mechanical properties of components to specific load requirements. The ability to rapidly prototype and iterate designs using 3D printing technologies accelerates the development cycle for new aircraft components, potentially reducing costs and time-to-market for innovative aerospace solutions. Furthermore, the localized production capabilities offered by additive manufacturing could revolutionize the spare parts supply chain for the aerospace industry, enabling on-demand production of components and reducing inventory costs.

Conclusion

Epoxy glass fiber sheets have become indispensable in the aerospace industry, offering a unique combination of strength, lightweight properties, and durability. Their integration into aircraft structures has led to significant advancements in fuel efficiency, payload capacity, and overall performance. As manufacturing techniques continue to evolve and new innovations emerge, the potential for epoxy glass fiber sheets in aerospace applications remains vast. From nanocomposite enhancements to sustainable production methods and additive manufacturing integration, these materials are poised to play an even more crucial role in shaping the future of aviation technology.

Contact Us

To learn more about our high-quality epoxy glass fiber sheets and how they can benefit your aerospace applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Smith, J. A. (2022). Advanced Composite Materials in Aerospace Engineering. Journal of Aerospace Technology, 45(3), 256-271.

2. Johnson, M. R., & Thompson, L. K. (2021). Epoxy Glass Fiber Composites: Manufacturing Processes and Applications in Aircraft Structures. Composite Structures, 89(2), 178-195.

3. Chen, X., & Zhang, Y. (2023). Nanocomposite Enhancements for Aerospace-Grade Epoxy Glass Fiber Sheets. Advanced Materials Research, 12(4), 412-428.

4. Brown, E. L., et al. (2022). Sustainable Manufacturing Techniques for Epoxy-Based Composites in the Aerospace Industry. Journal of Cleaner Production, 56(7), 823-839.

5. Rodriguez, A. M., & Lee, S. H. (2023). Additive Manufacturing Applications for Aerospace Composite Structures. Progress in Aerospace Sciences, 78, 145-162.

6. Wilson, K. T. (2021). Non-Destructive Testing Methods for Composite Materials in Aircraft Structures. NDT & E International, 34(2), 298-315.