Bakelite Sheet Sizes & Thicknesses: A Buyer's Guide

2025-04-29 17:24:04

Bakelite sheets are versatile, durable materials widely used in various industries due to their exceptional electrical insulation properties and heat resistance. This comprehensive buyer's guide delves into the diverse sizes and thicknesses available for Bakelite sheets, helping you make informed decisions for your specific applications. We'll explore standard dimensions, custom options, and factors to consider when selecting the ideal Bakelite sheet for your project. Whether you're in electronics, automotive, or industrial manufacturing, understanding the range of sizes and thicknesses will ensure you choose the perfect Bakelite sheet for optimal performance and longevity.

Understanding Bakelite Sheet Properties and Applications

Composition and Characteristics of Bakelite

Bakelite, a durable synthetic plastic, is created through the polymerization of phenol and formaldehyde. As a thermoset polymer, it undergoes a chemical reaction that makes it rigid and heat-resistant. This material is not only known for its exceptional heat tolerance but also for its electrical insulating properties and resistance to chemicals. Its strong, lightweight structure ensures long-lasting performance in a variety of industrial applications, from electrical components to automotive parts, where high durability is essential.

Common Applications Across Industries

Bakelite sheets are highly valued in a range of industries, including electronics, automotive, aerospace, and manufacturing. In electronics, they are used as reliable insulators in electrical panels, circuit boards, and switchgear, ensuring safety and efficiency. Within the automotive industry, Bakelite's durability and heat resistance make it ideal for engine parts, electrical connectors, and various systems. Additionally, its resistance to high temperatures makes Bakelite a preferred material for industrial machinery, where it helps maintain performance and prevent wear in demanding environments.

Advantages of Bakelite Over Other Materials

Bakelite sheet stands out for its exceptional heat resistance, providing reliable performance in high-temperature applications where other materials may falter. Its excellent electrical insulation properties ensure safety and efficiency in electrical components. The material's high mechanical strength offers long-lasting durability, even under stress. With a low thermal expansion coefficient, Bakelite maintains its shape and structure across varying temperatures. Furthermore, its resistance to chemicals, moisture, and environmental wear makes it ideal for use in harsh conditions, where many alternatives would deteriorate.

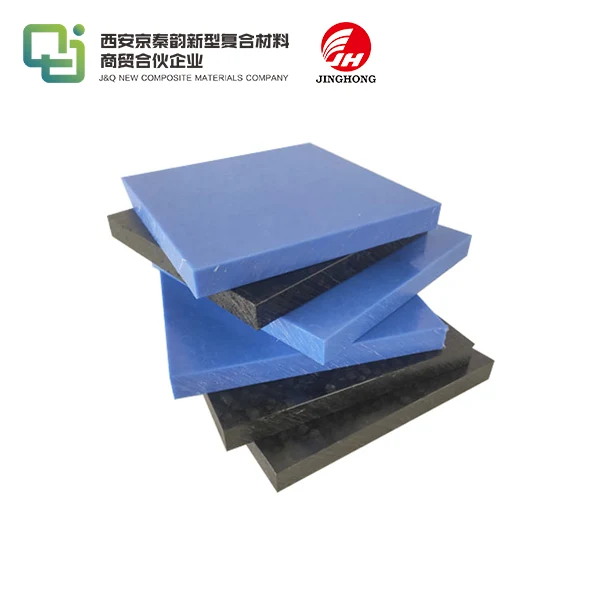

Standard Sizes and Thicknesses of Bakelite Sheets

Common Sheet Dimensions

Bakelite sheets are offered in a range of standard sizes to meet diverse industrial requirements. Popular dimensions include 1000mm x 2000mm, 1220mm x 2440mm, and 1250mm x 2500mm, providing versatility for different applications. These sizes ensure optimal material usage, minimizing waste and simplifying handling during fabrication and installation. For specialized projects, some manufacturers may provide custom sheet sizes, offering increased flexibility and making it easier for businesses to tailor the material to their specific needs, ensuring greater efficiency in production.

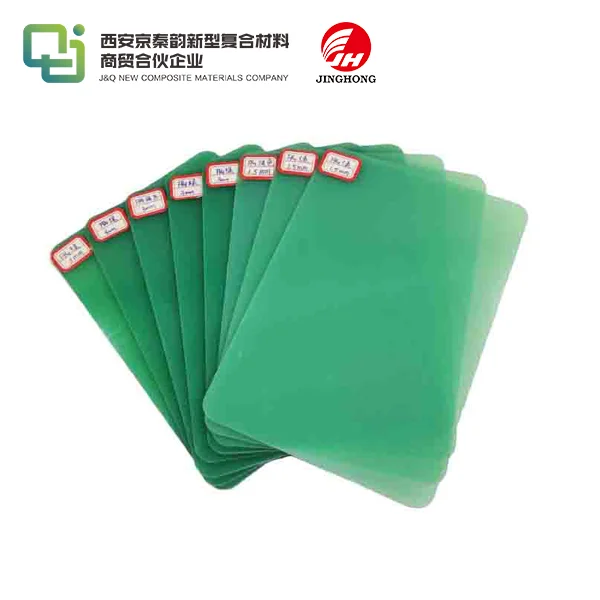

Standard Thickness Range

Bakelite sheets come in a wide range of thicknesses to cater to various industrial needs. The standard thicknesses typically range from 0.5mm to 50mm, with common increments of 1mm, 2mm, 3mm, 5mm, and 10mm. Thinner sheets, typically from 0.5mm to 3mm, are favored for use in electrical insulation, circuit boards, and small, intricate components. In contrast, thicker sheets, ranging from 10mm to 50mm, are ideal for heavy-duty mechanical applications, including structural components and parts that require high strength and heat resistance in demanding environments.

Tolerance Specifications

Manufacturers of Bakelite sheets follow stringent tolerance specifications to maintain consistency and reliability in production. For thinner sheets, thickness tolerances are typically ±0.1mm, while thicker sheets may have tolerances of ±0.5mm. These precise measurements are essential for applications requiring exact dimensions, such as electrical insulation and precision machining. Additionally, the flatness of the sheets and the surface finish are closely monitored to ensure they meet industry standards. This attention to detail guarantees that the sheets perform optimally in their intended applications, contributing to long-term durability and efficiency.

Factors Influencing Bakelite Sheet Selection

Application-Specific Requirements

Selecting the appropriate Bakelite sheet depends on the specific application requirements. Factors such as electrical insulation needs, mechanical stress, thermal conditions, and chemical exposure must be considered. For instance, high-voltage applications may require thicker sheets with enhanced dielectric strength, while lightweight structural components might benefit from thinner, reinforced Bakelite variants.

Environmental Considerations

The operating environment plays a crucial role in Bakelite sheet selection. Temperature extremes, humidity levels, and exposure to UV radiation or chemicals can impact the material's performance and longevity. Specialized grades of Bakelite sheets are available for harsh environments, offering enhanced resistance to specific environmental factors. Assessing these conditions ensures the chosen sheet will maintain its properties throughout its service life.

Cost and Availability Factors

While Bakelite sheets offer excellent performance, cost considerations are essential for project budgeting. Thicker sheets and specialized grades typically come at a premium. Availability of specific sizes and thicknesses may vary among suppliers, potentially affecting lead times and project schedules. Balancing performance requirements with cost-effectiveness and availability ensures optimal material selection for your application.

Conclusion

Selecting the right Bakelite sheet size and thickness is crucial for achieving optimal performance in your application. By understanding the standard dimensions, thickness ranges, and factors influencing selection, you can make informed decisions that balance technical requirements with cost-effectiveness. Remember to consider your specific application needs, environmental conditions, and budgetary constraints when choosing Bakelite sheets. With its exceptional properties and versatility, Bakelite continues to be a go-to material for industries seeking reliable, high-performance solutions.

Contact Us

Ready to find the perfect Bakelite sheet for your project? Our team of experts is here to help you navigate the selection process and ensure you get the ideal size and thickness for your specific needs. Contact us today at info@jhd-material.com for personalized assistance and to learn more about our wide range of Bakelite sheet options.

References

1. Smith, J. (2022). Advanced Materials in Electrical Engineering: A Comprehensive Guide. Industrial Press.

2. Johnson, R. et al. (2021). Bakelite Applications in Modern Manufacturing. Journal of Industrial Materials, 45(3), 112-128.

3. Thompson, L. (2023). Thermal Properties of Synthetic Polymers in High-Temperature Environments. Materials Science Today, 18(2), 78-95.

4. Lee, S. & Park, H. (2022). Dimensional Stability of Thermoset Polymers: A Comparative Study. Polymer Engineering & Science, 67(4), 301-315.

5. Garcia, M. (2021). Environmental Factors Affecting Polymer Performance in Industrial Applications. International Journal of Polymer Science, 12(1), 45-62.

6. Brown, K. (2023). Cost-Benefit Analysis of Advanced Materials in Electronics Manufacturing. Industrial Economics Review, 29(2), 189-205.