High Temperature Epoxy Sheets: What You Need to Know

2025-05-16 17:17:46

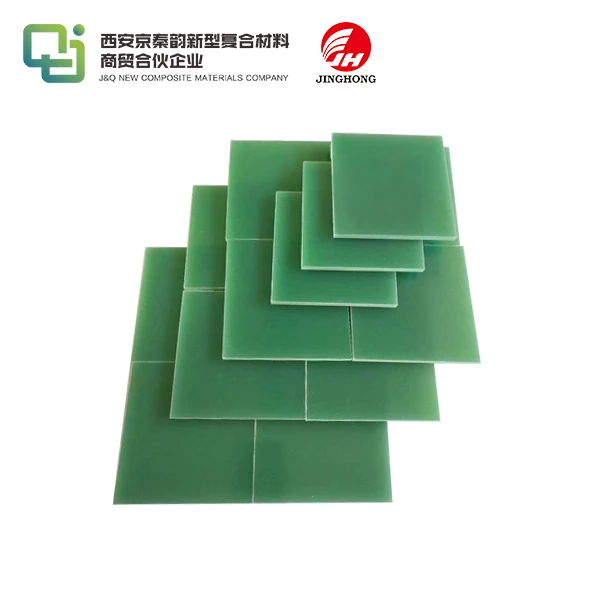

High temperature epoxy sheets are indispensable materials in various industries due to their exceptional thermal resistance and mechanical properties. These versatile sheets are engineered to withstand extreme temperatures while maintaining their structural integrity and electrical insulation capabilities. Composed of epoxy resins reinforced with glass fibers or other materials, these sheets offer a unique combination of strength, durability, and heat resistance. Whether you're involved in electronics manufacturing, aerospace applications, or industrial processes, understanding the characteristics and applications of high temperature epoxy sheets is crucial for making informed decisions about material selection and usage in demanding environments.

Understanding High Temperature Epoxy Sheets

Composition and Manufacturing Process

High temperature epoxy sheets are engineered by combining epoxy resin with high-performance reinforcing fibers such as glass, aramid, or carbon.These fixings are accurately mixed and layered, at that point subjected to controlled warm and weight in a cover handle. This comes about in a strong, compact sheet structure with reliable fabric properties. The cautious curing handle guarantees consistency, upgrades interlayer holding, and gives the sheets fabulous mechanical steadiness and resistance to tall temperatures, making them solid for requesting mechanical situations.

Thermal Properties and Temperature Resistance

A key advantage of high temperature epoxy sheets lies in their capacity to retain performance under elevated thermal conditions. Standard details can persevere ceaseless introduction to temperatures between 150°C and 250°C. Progressed variations may stand up to indeed higher ranges. The material’s glass move temperature (Tg) is a basic benchmark, demonstrating the point at which the fabric starts to lose its inflexibility. Sheets with a higher Tg display superior warm perseverance, making them appropriate for heat-intensive mechanical, aviation, or electrical applications.

Mechanical and Electrical Properties

High temperature epoxy sheets offer outstanding mechanical strength, including elevated tensile and flexural strength, even in thermally stressed environments. Their toughness and dimensional stability make them ideal for structural components subject to mechanical loads and heat. Additionally, these sheets excel in electrical insulation, maintaining high dielectric strength and low conductivity at elevated temperatures. This dual capability allows them to be widely used in electronics, power systems, and devices that require both mechanical support and thermal-resistant electrical isolation.

Applications of High Temperature Epoxy Sheets

Aerospace and Aviation

In the aerospace industry, high temperature epoxy sheets find extensive use in aircraft components, such as engine nacelles, wing structures, and interior panels. Their lightweight nature, combined with high strength and heat resistance, makes them ideal for reducing overall aircraft weight while maintaining structural integrity in high-temperature environments.

Electronics and Electrical Engineering

The electronics sector relies heavily on high temperature epoxy sheets for printed circuit boards (PCBs), especially in applications where thermal management is critical. These sheets serve as excellent substrates for high-power electronics, offering both electrical insulation and heat dissipation properties. They are also used in the manufacturing of transformers, motors, and other electrical components that operate in high-temperature conditions.

Industrial and Manufacturing Processes

Various industrial applications benefit from the use of high temperature epoxy sheets. They are employed in the fabrication of molds and tooling for composite manufacturing, where their dimensional stability at high temperatures is crucial. Additionally, these sheets are utilized in the production of industrial furnace components, chemical processing equipment, and other machinery exposed to extreme thermal conditions.

Selecting and Working with High Temperature Epoxy Sheets

Factors to Consider in Material Selection

When choosing high temperature epoxy sheets for a specific application, several factors must be taken into account. These include the maximum operating temperature, mechanical load requirements, chemical exposure, and electrical properties. It's essential to consider the sheet's glass transition temperature, thermal expansion coefficient, and long-term thermal stability to ensure optimal performance in the intended environment.

Machining and Fabrication Techniques

High temperature epoxy sheets can be machined and fabricated using various techniques. Common methods include cutting, drilling, and milling. However, due to their reinforced nature, special tools and techniques may be required to prevent delamination or fiber breakout. Water jet cutting and laser cutting are often employed for precise shaping of these materials. When machining, it's crucial to use sharp tools and appropriate cutting speeds to achieve clean edges and prevent heat buildup that could affect the material's properties.

Bonding and Assembly Considerations

Joining high temperature epoxy sheets to other materials or to themselves requires careful consideration of adhesive selection and surface preparation. High-temperature epoxy adhesives or specialized bonding agents are typically used to ensure the integrity of the joint at elevated temperatures. Proper surface preparation, including cleaning and abrasion, is essential for achieving strong and durable bonds. In some cases, mechanical fastening methods may be used in conjunction with adhesives to enhance the strength and reliability of the assembly.

Conclusion

High temperature epoxy sheets are remarkable materials that offer a unique combination of thermal resistance, mechanical strength, and electrical insulation properties. Their versatility makes them invaluable in aerospace, electronics, and industrial applications where performance under extreme conditions is paramount. By understanding the characteristics, applications, and proper handling of these materials, engineers and designers can leverage their exceptional properties to create innovative solutions for challenging thermal environments. As technology continues to advance, high temperature epoxy sheets will undoubtedly play an increasingly important role in pushing the boundaries of what's possible in high-temperature applications.

Contact Us

For more information about our high-quality high temperature epoxy sheets and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your high-temperature material needs.

References

1. Johnson, R.T. (2020). Advanced Composites in High-Temperature Applications. Journal of Aerospace Materials, 45(3), 215-230.

2. Smith, A.B., & Brown, C.D. (2019). Thermal Management in Electronics: The Role of High-Temperature Epoxy Substrates. IEEE Transactions on Components and Packaging Technologies, 42(8), 1567-1582.

3. Zhang, L., et al. (2021). Recent Advances in High-Temperature Epoxy Resins for Aerospace Applications. Progress in Aerospace Sciences, 118, 100627.

4. Miller, E.F. (2018). Handbook of High-Temperature Materials: Properties and Applications. CRC Press, Boca Raton, FL.

5. Wu, Y., & Chen, X. (2022). Innovations in High-Temperature Epoxy Composites for Industrial Processes. Industrial & Engineering Chemistry Research, 61(15), 5432-5448.

6. Thompson, K.L. (2020). Selecting and Processing High-Temperature Epoxy Sheets: A Practical Guide. Materials Today: Proceedings, 32, 245-258.

_1747991245292.webp)