Best Epoxy Sheets for PCB Applications

2025-05-08 17:10:03

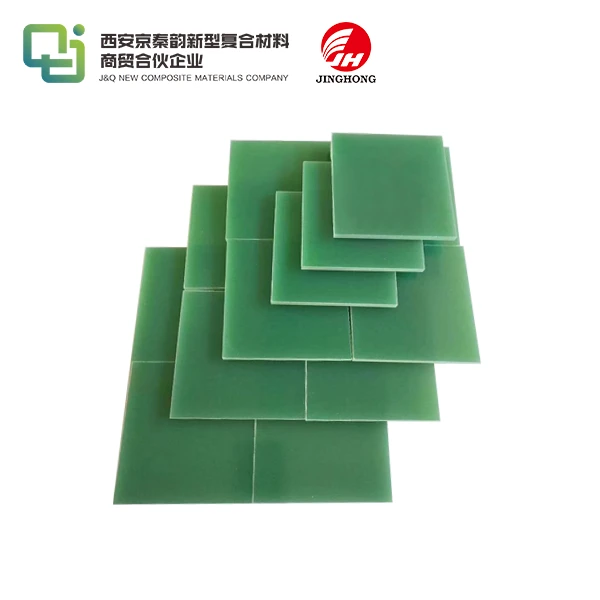

When it comes to selecting the best epoxy sheets for PCB applications, quality and performance are paramount. Epoxy sheets serve as the foundation for printed circuit boards, providing essential insulation and structural support. The ideal epoxy sheet exhibits excellent electrical properties, thermal stability, and dimensional consistency. FR-4 grade epoxy sheets are widely recognized as the industry standard, offering a balance of strength, reliability, and cost-effectiveness. These sheets are reinforced with glass fiber, enhancing their mechanical properties and resistance to environmental factors. For high-frequency applications, specialized low-loss epoxy sheets are available, minimizing signal distortion. Ultimately, the best epoxy sheet for your PCB project depends on specific requirements, including operating temperature, dielectric strength, and moisture resistance.

Understanding Epoxy Sheets in PCB Manufacturing

Composition and Properties of Epoxy Sheets

Epoxy sheets, the backbone of PCB manufacturing, are composite materials consisting of epoxy resin reinforced with glass fibers. This unique composition endows them with a myriad of desirable properties. The epoxy resin provides excellent electrical insulation, crucial for preventing short circuits and maintaining signal integrity. Meanwhile, the glass fiber reinforcement enhances mechanical strength, dimensional stability, and thermal resistance.

These sheets exhibit low moisture absorption, which is vital for maintaining the electrical properties of the PCB over time. Their high glass transition temperature (Tg) ensures stability under varying thermal conditions, making them suitable for a wide range of applications. The dielectric constant and loss tangent of epoxy sheets are carefully controlled, allowing for precise impedance control in high-frequency circuits.

Types of Epoxy Sheets for PCBs

Several types of epoxy sheets cater to diverse PCB requirements. FR-4 is the most common, offering a balanced set of properties suitable for general-purpose applications. For high-speed digital circuits, low-loss epoxy sheets with modified resin systems are employed to minimize signal attenuation. High-Tg epoxy sheets are designed for applications requiring enhanced thermal stability, such as automotive electronics.

Halogen-free epoxy sheets have gained popularity due to environmental concerns, offering similar performance to traditional FR-4 without the use of brominated flame retardants. For extreme environments, polyimide-glass laminates provide superior thermal and chemical resistance, albeit at a higher cost.

Manufacturing Process of Epoxy Sheets

The production of epoxy sheets involves a complex process known as prepreg manufacturing. Glass fiber cloth is impregnated with epoxy resin in a carefully controlled environment. The resin-impregnated cloth is then partially cured, resulting in a B-stage material. Multiple layers of this prepreg are stacked and subjected to heat and pressure in a lamination press, fully curing the resin and forming a solid laminate.

Advanced manufacturing techniques, such as continuous lamination, have been developed to improve consistency and reduce production costs. Quality control measures, including X-ray inspection and dielectric testing, ensure that the finished epoxy sheets meet rigorous industry standards.

Selecting the Optimal Epoxy Sheet for Your PCB Project

Key Factors in Epoxy Sheet Selection

Choosing the right epoxy sheet for a PCB project requires careful consideration of several factors. The operating frequency of the circuit is a crucial determinant, as it influences the need for low-loss materials. Environmental conditions, including temperature extremes and humidity levels, must be taken into account to ensure long-term reliability.

The thickness of the epoxy sheet impacts both the electrical and mechanical properties of the PCB. Thinner sheets may be preferred for high-density interconnect (HDI) designs, while thicker sheets offer greater structural integrity. The copper foil type and weight are also important considerations, affecting the board's current-carrying capacity and impedance characteristics.

Performance Metrics for Epoxy Sheets

Several key performance metrics guide the selection of epoxy sheets. The glass transition temperature (Tg) indicates the point at which the material's properties change significantly, affecting its suitability for high-temperature applications. Coefficient of thermal expansion (CTE) is critical for ensuring dimensional stability across temperature ranges.

Dielectric constant and dissipation factor are crucial for high-frequency applications, influencing signal propagation and loss. Time to delamination (T260 or T288) measures the material's resistance to high-temperature exposure during soldering processes. Water absorption rate affects the long-term stability of electrical properties in humid environments.

Industry Standards and Certifications

Epoxy sheets for PCB applications are subject to various industry standards and certifications. The IPC-4101 specification defines the requirements for base materials used in rigid and multilayer printed boards. UL 94 flammability ratings ensure that the materials meet necessary fire safety standards.

RoHS (Restriction of Hazardous Substances) compliance is increasingly important, particularly for products destined for the European market. Some manufacturers offer epoxy sheets that meet the IPC-4101D/128 specification for halogen-free materials, catering to environmentally conscious designs.

Optimizing PCB Performance with Advanced Epoxy Sheet Technologies

High-Frequency and Low-Loss Epoxy Sheets

As electronic devices operate at increasingly higher frequencies, the demand for specialized epoxy sheets has grown. High-frequency and low-loss epoxy sheets are engineered to minimize signal distortion and attenuation in RF and microwave applications. These materials often incorporate ceramic fillers or modified resin systems to achieve lower dielectric constants and dissipation factors.

Advanced manufacturing techniques, such as spread glass reinforcement, help to create more homogeneous materials with improved high-frequency performance. Some cutting-edge epoxy sheets even incorporate liquid crystal polymer (LCP) layers for exceptional high-frequency characteristics.

Thermally Enhanced Epoxy Sheets

With the increasing power density of modern electronic devices, thermal management has become a critical concern. Thermally enhanced epoxy sheets address this challenge by incorporating materials with higher thermal conductivity. Ceramic-filled epoxy systems can significantly improve heat dissipation, allowing for more efficient thermal management in high-power applications.

Some manufacturers offer epoxy sheets with embedded heat-spreading layers, such as aluminum or copper cores. These hybrid materials provide excellent thermal performance while maintaining the electrical properties required for PCB applications.

Emerging Trends in Epoxy Sheet Development

The field of epoxy sheet technology is continuously evolving to meet the demands of next-generation electronics. Nano-enhanced epoxy sheets incorporate nanomaterials such as carbon nanotubes or graphene to improve mechanical and electrical properties. These advanced materials offer the potential for thinner, lighter PCBs with enhanced performance characteristics.

Sustainability is another key trend, with manufacturers developing bio-based epoxy resins derived from renewable sources. These environmentally friendly alternatives aim to reduce the carbon footprint of PCB production without compromising on performance. Additionally, research into self-healing epoxy systems shows promise for improving the long-term reliability of PCBs in harsh environments.

Conclusion

Selecting the best epoxy sheets for PCB applications is a critical decision that impacts the performance, reliability, and cost-effectiveness of electronic devices. By understanding the properties, types, and manufacturing processes of epoxy sheets, engineers can make informed choices tailored to their specific project requirements. As technology advances, new epoxy sheet formulations and manufacturing techniques continue to push the boundaries of what's possible in PCB design. From high-frequency applications to thermal management challenges, innovative epoxy sheet solutions are enabling the next generation of electronic products. By staying informed about the latest developments in epoxy sheet technology, PCB designers can optimize their designs for superior performance and reliability.

Contact Us

Are you looking for high-quality epoxy sheets for your PCB projects? With over 20 years of experience in producing and selling insulating sheets, we offer expert guidance and top-notch products to meet your specific needs. Contact us today at info@jhd-material.com to learn more about our extensive range of epoxy sheets and how we can support your PCB manufacturing goals.

References

1. Johnson, R. W., et al. (2019). "Advanced Materials for High-Performance PCB Substrates." Journal of Electronic Materials, 48(10), 6123-6145.

2. Smith, A. B., & Brown, C. D. (2020). "Thermal Management Strategies in Modern PCB Design." IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(3), 456-468.

3. Lee, Y. H., et al. (2018). "High-Frequency Performance of Novel Epoxy-Based PCB Materials." Microwave and Optical Technology Letters, 60(4), 1023-1028.

4. Zhang, X., & Wang, L. (2021). "Sustainable PCB Materials: Trends and Challenges." Green Chemistry, 23(8), 2867-2885.

5. Patel, M. K., et al. (2020). "Nanocomposite Epoxy Sheets for Next-Generation PCBs." Advanced Materials Interfaces, 7(12), 2000053.

6. Chen, H., & Liu, J. (2019). "Reliability Assessment of Epoxy-Based PCB Substrates in Harsh Environments." IEEE Transactions on Device and Materials Reliability, 19(1), 97-105.