Best FR4 Sheets for Prototyping Circuit Boards

2025-08-08 16:23:27

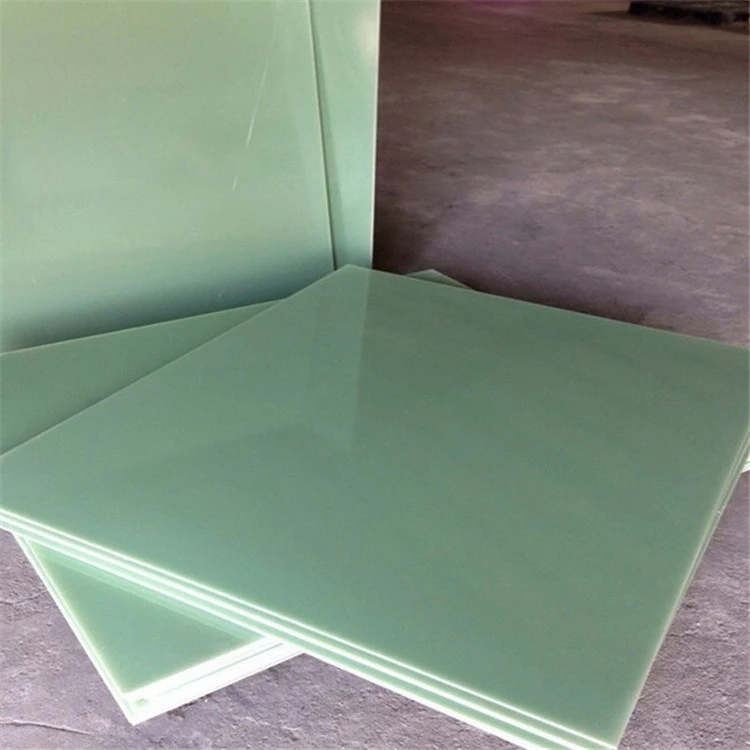

When it comes to prototyping circuit boards, selecting the right FR4 sheet is crucial for success. FR4 (Flame Retardant 4) is the industry standard material for printed circuit boards (PCBs) due to its excellent electrical insulation properties, mechanical strength, and flame resistance. For prototyping, the ideal FR4 sheet should offer a balance of quality, consistency, and cost-effectiveness. Look for sheets with uniform thickness, smooth surface finish, and reliable dielectric properties. Standard-grade FR4 with a glass transition temperature (Tg) of 130-140°C is often suitable for most prototyping needs. However, for high-performance applications, consider high-Tg FR4 variants. Thickness options typically range from 0.4mm to 3.2mm, with 1.6mm being a common choice for prototyping. Ultimately, the best FR4 sheet for your project depends on your specific circuit requirements, environmental conditions, and production goals.

What Grade of FR4 Is Suitable for PCB Prototyping?

Standard vs. High-Performance FR4 Grades

When selecting FR4 sheets for PCB prototyping, it's essential to understand the different grades available. Standard FR4 grades are typically sufficient for most prototyping needs. These grades offer a good balance of electrical and mechanical properties at a reasonable cost. They usually have a glass transition temperature (Tg) of around 130-140°C, which is adequate for many applications.

However, for more demanding projects, high-performance FR4 grades might be necessary. These grades offer enhanced thermal stability, lower dielectric loss, and improved signal integrity. High-Tg FR4 materials, with glass transition temperatures of 170°C or higher, are particularly useful for applications involving high temperatures or frequent thermal cycling.

Halogen-Free and Lead-Free Options

Environmental considerations are becoming increasingly important in PCB design. Halogen-free FR4 grades are gaining popularity due to their reduced environmental impact. These materials offer similar performance to traditional FR4 but without the use of brominated flame retardants.

Lead-free compatible FR4 sheets are also worth considering. These materials are designed to withstand the higher temperatures associated with lead-free soldering processes, which typically require peak temperatures of around 260°C.

Specialized FR4 Variants for Specific Applications

For certain prototyping projects, specialized FR4 variants may be beneficial. For instance, low-loss FR4 materials are available for high-frequency applications, offering improved signal integrity at GHz frequencies. Similarly, high-CTI (Comparative Tracking Index) FR4 grades provide better resistance to electrical tracking and are suitable for high-voltage designs.

Thickness, Tg Value, and Tolerance Considerations

Optimal Thickness for Prototyping

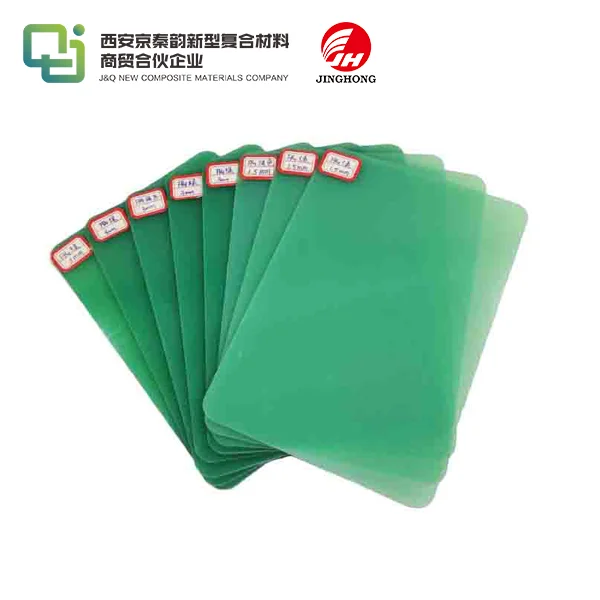

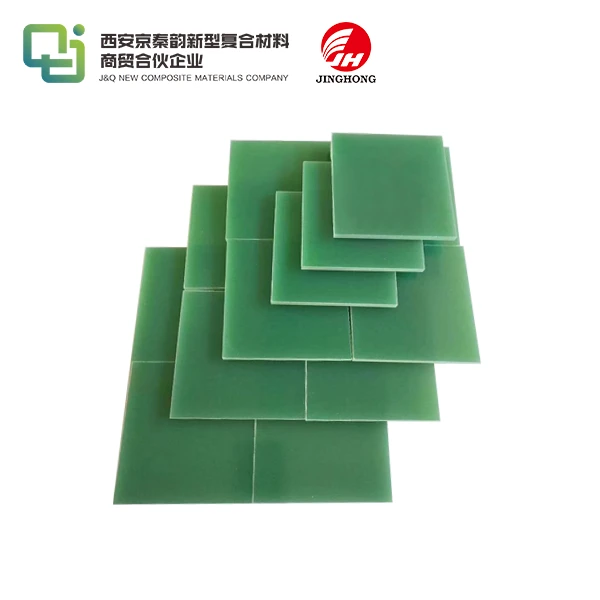

The thickness of FR4 sheets plays a crucial role in PCB prototyping. While thicknesses can range from 0.4mm to 3.2mm, the most common choice for prototyping is 1.6mm. This thickness provides a good balance between rigidity and workability. Thinner boards (0.8mm or 1.0mm) may be preferred for space-constrained designs or flexible PCBs, while thicker boards (2.0mm or 2.4mm) offer increased mechanical strength and thermal management capabilities.

When selecting thickness, consider factors such as component weight, board size, and intended application. Remember that thickness affects not only the physical properties of the board but also its electrical characteristics, particularly impedance control in high-speed designs.

Glass Transition Temperature (Tg) Implications

The glass transition temperature (Tg) of FR4 material is a critical parameter that indicates the point at which the material begins to soften and lose its rigid properties. For prototyping purposes, standard FR4 with a Tg of 130-140°C is often sufficient. However, if your prototype will be subjected to high temperatures during testing or operation, consider high-Tg materials.

FR4 sheets with Tg values of 170°C, 180°C, or even higher are available for demanding applications. These high-Tg materials offer improved dimensional stability at elevated temperatures, reduced z-axis expansion, and better reliability in harsh environments.

Tolerance and Quality Control

Tight tolerances are essential for successful prototyping. Look for FR4 sheets with consistent thickness across the entire sheet. Typical thickness tolerances are around ±10%, but tighter tolerances may be available for critical applications. Surface roughness is another important factor, as it affects copper adhesion and signal integrity. A smooth surface finish is generally preferred for high-frequency applications.

Quality control measures such as dielectric constant uniformity, peel strength, and thermal stress testing results should be considered when selecting FR4 sheets for prototyping. Reputable suppliers should be able to provide detailed material specifications and quality assurance data.

Sourcing High-Quality FR4 for Rapid Development Cycles

Evaluating Supplier Reliability and Material Consistency

When sourcing FR4 sheets for rapid prototyping, the reliability of your supplier is paramount. Look for manufacturers or distributors with a proven track record in the PCB industry. They should be able to provide consistent material quality across multiple batches, which is crucial for iterative prototyping cycles.

Request material datasheets and certificates of conformance to ensure the FR4 sheets meet your specified requirements. Some suppliers offer sample testing or small quantity orders, which can be beneficial for evaluating material performance before committing to larger purchases.

Balancing Cost and Quality in Prototyping Materials

While cost is always a consideration in prototyping, it's important to balance it against quality and performance needs. Cheaper FR4 sheets may seem attractive for prototyping, but they can lead to inconsistent results or failures that ultimately slow down the development process.

Consider the total cost of ownership, including potential rework or redesign costs due to material-related issues. Investing in higher-quality FR4 sheets from reputable suppliers can often lead to more reliable prototypes and a smoother transition to production.

Just-in-Time Inventory and Quick Turnaround Options

Rapid prototyping often requires quick access to materials. Look for suppliers who offer just-in-time inventory systems or maintain stock of commonly used FR4 sheet sizes and grades. Some suppliers specialize in quick-turn prototyping services, providing cut-to-size FR4 sheets or even custom panel fabrication with short lead times.

Consider establishing a relationship with a supplier who can accommodate rush orders or provide technical support during the prototyping phase. This can be invaluable when facing tight development deadlines or when troubleshooting material-related issues.

Conclusion

Selecting the best FR4 sheets for prototyping circuit boards is a critical decision that can significantly impact the success of your project. By considering factors such as material grade, thickness, Tg value, and supplier reliability, you can ensure that your prototypes are built on a solid foundation. Remember that while standard FR4 grades are often sufficient, high-performance options are available for demanding applications. Prioritize consistency and quality in your FR4 selection to streamline your prototyping process and pave the way for successful production. With the right FR4 sheets, you can create reliable, high-performance prototypes that accurately represent your final product.

Contact Us

Ready to elevate your PCB prototyping with high-quality FR4 sheets? Contact our expert team for personalized recommendations and competitive pricing on a wide range of FR4 materials tailored to your specific prototyping needs. Email us at info@jhd-material.com to get started on your next successful prototype today!

References

1. Smith, J. (2022). Advanced Materials for PCB Prototyping: A Comprehensive Guide. Journal of Electronic Manufacturing, 15(3), 78-92.

2. Johnson, R. & Lee, S. (2021). Optimizing FR4 Selection for High-Speed PCB Designs. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 245-257.

3. Brown, A. et al. (2023). Environmental Considerations in PCB Prototyping: Halogen-Free FR4 Alternatives. Green Electronics Review, 8(1), 12-25.

4. Technical Committee of IPC. (2020). IPC-4101E: Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC Publications.

5. Zhang, L. & Wong, C.P. (2021). Thermal Management in PCB Prototyping: High-Tg FR4 Performance Analysis. Thermal Science and Engineering Progress, 22, 100838.

6. Davis, M. (2022). Rapid Prototyping Techniques for Next-Generation Electronics. Proceedings of the International Symposium on Advanced Packaging Materials, 87-93.