Can FR4 Fiberglass Sheets Resist Chemicals?

2025-08-11 16:53:49

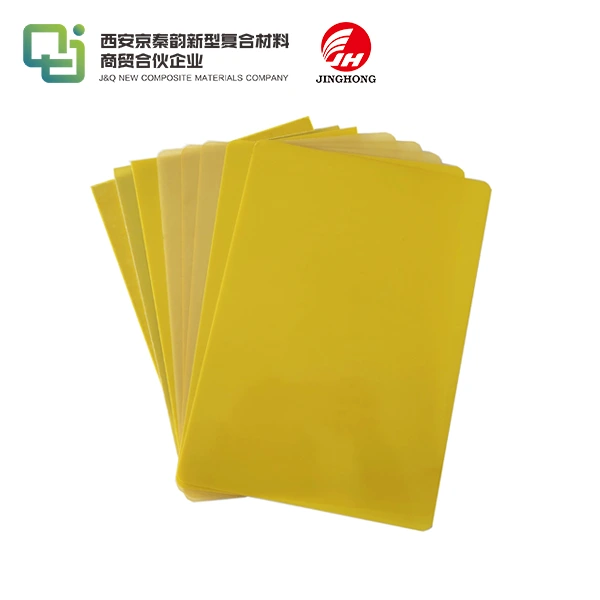

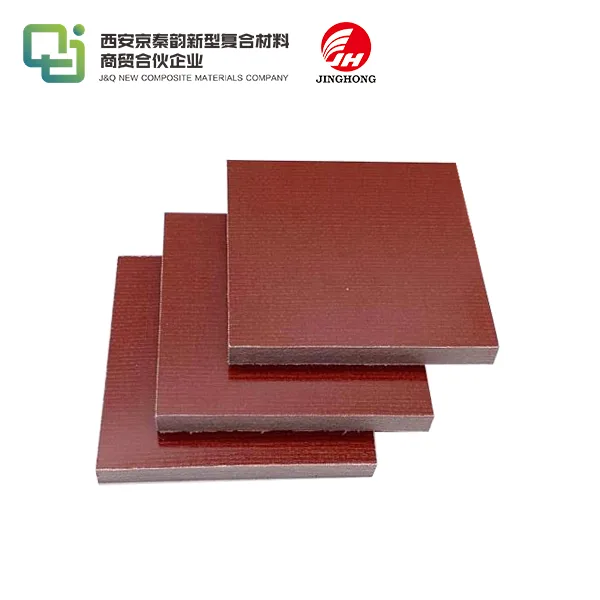

FR4 fiberglass sheets exhibit remarkable chemical resistance, making them a preferred choice in various industries where exposure to harsh substances is common. These versatile laminates, composed of woven glass fiber reinforced with epoxy resin, demonstrate excellent resilience against a wide range of chemicals, including acids, alkalis, and organic solvents. Their ability to withstand corrosive environments stems from the inherent properties of both the glass fibers and the epoxy matrix. While FR4 sheets offer impressive chemical resistance, it's crucial to note that their performance can vary depending on the specific chemical, concentration, temperature, and duration of exposure. For applications involving prolonged contact with aggressive chemicals, it's advisable to conduct thorough testing to ensure optimal performance and longevity.

How Does FR4 Perform in Acidic and Alkaline Environments?

Resistance to Acidic Solutions

FR4 fiberglass sheets demonstrate commendable resistance to various acidic solutions. The epoxy resin matrix provides a protective barrier against many common acids, including hydrochloric acid, sulfuric acid, and nitric acid. However, the concentration of the acid and the duration of exposure play crucial roles in determining the extent of resistance. Generally, FR4 performs well in mild to moderate acidic conditions, maintaining its structural integrity and electrical properties. For instance, when exposed to a 10% sulfuric acid solution at room temperature, FR4 sheets show minimal degradation over extended periods.

Behavior in Alkaline Solutions

In alkaline environments, FR4 fiberglass sheets also exhibit good resistance. The material can withstand exposure to common alkaline substances such as sodium hydroxide and potassium hydroxide without significant deterioration. This resistance is particularly beneficial in applications where the material may come into contact with cleaning agents or industrial processes involving alkaline solutions. However, as with acids, the concentration and exposure time are critical factors. Prolonged exposure to highly concentrated alkaline solutions may eventually lead to some degradation of the epoxy matrix, potentially affecting the material's mechanical properties.

Temperature Considerations

It's important to note that temperature plays a significant role in the chemical resistance of FR4 fiberglass sheets. Elevated temperatures can accelerate chemical reactions and potentially reduce the material's resistance to both acidic and alkaline substances. For instance, while FR4 might resist a certain concentration of hydrochloric acid at room temperature, its performance could be compromised if exposed to the same solution at higher temperatures. Therefore, when assessing the suitability of FR4 for specific applications, it's crucial to consider not only the chemical environment but also the operating temperature range.

Chemical Resistance Ratings for Common Industrial Solvents

Resistance to Organic Solvents

FR4 fiberglass sheets demonstrate varying degrees of resistance to organic solvents, a property that enhances their versatility in industrial applications. These laminates generally exhibit good resistance to aliphatic hydrocarbons such as hexane and heptane, showing minimal swelling or degradation when exposed to these substances. However, their performance against aromatic hydrocarbons like benzene or toluene may be less robust, potentially leading to some softening or swelling of the epoxy matrix over prolonged exposure. Ketones and esters, including acetone and ethyl acetate, can also affect FR4 to varying degrees, necessitating careful consideration in applications where these solvents are present.

Performance with Halogenated Solvents

Halogenated solvents pose a unique challenge to FR4 fiberglass sheets. Chlorinated solvents such as methylene chloride or trichloroethylene can be particularly aggressive, potentially causing significant swelling or degradation of the epoxy resin. The resistance of FR4 to these solvents is generally lower compared to its performance against other chemical groups. In applications where exposure to halogenated solvents is unavoidable, it's crucial to conduct thorough compatibility tests and consider alternative materials or protective measures if necessary.

Alcohol and Ether Resistance

FR4 fiberglass sheets typically exhibit good resistance to alcohols and ethers. Common alcohols like methanol, ethanol, and isopropanol generally have minimal impact on the material's properties, even with prolonged exposure. This resistance makes FR4 suitable for applications in industries where alcohol-based cleaning or processing is common. Ethers, such as diethyl ether or tetrahydrofuran, may have a more pronounced effect, especially at higher concentrations or elevated temperatures. As with all chemical exposures, the specific conditions of use, including concentration, temperature, and duration, should be carefully evaluated to ensure the material's suitability for the intended application.

Long-Term Durability of FR4 in Corrosive Conditions

Factors Influencing Long-Term Performance

The long-term durability of FR4 fiberglass sheets in corrosive conditions is influenced by several key factors. The specific chemical environment, including the type and concentration of corrosive substances, plays a primary role. Additionally, exposure duration, temperature fluctuations, and mechanical stresses can significantly impact the material's longevity. The quality of the FR4 laminate, including the grade of epoxy resin used and the manufacturing process, also affects its resistance to degradation over time. Environmental factors such as humidity and UV exposure can further influence the material's long-term performance, potentially accelerating chemical reactions or altering the material's surface properties.

Degradation Mechanisms and Prevention

Understanding the mechanisms of degradation is crucial for predicting and preventing long-term damage to FR4 fiberglass sheets in corrosive environments. Common degradation mechanisms include hydrolysis of the epoxy matrix, delamination due to chemical attack at the fiber-matrix interface, and surface erosion. To mitigate these effects, various strategies can be employed. Surface treatments or coatings can provide an additional barrier against chemical ingress. Proper design considerations, such as minimizing exposed edges or incorporating stress-relief features, can help reduce the risk of delamination. Regular inspection and maintenance protocols are essential for early detection of any signs of degradation, allowing for timely intervention and potentially extending the service life of FR4 components.

Case Studies and Real-World Performance

Examining case studies and real-world applications provides valuable insights into the long-term durability of FR4 fiberglass sheets in corrosive conditions. For instance, in the electronics industry, FR4 circuit boards have demonstrated remarkable longevity in environments exposed to flux residues and cleaning solvents. In chemical processing plants, FR4 components used in control panels and electrical enclosures have shown sustained performance over many years, despite exposure to harsh industrial atmospheres. However, it's important to note that performance can vary significantly based on specific application conditions. Documenting and analyzing long-term performance data from diverse applications helps in refining material selection criteria and improving predictive models for FR4 durability in corrosive environments.

Conclusion

FR4 fiberglass sheets demonstrate impressive chemical resistance across a wide spectrum of substances, making them a versatile choice for numerous industrial applications. Their ability to withstand acidic, alkaline, and many organic solvents underscores their durability and reliability. However, the material's performance can vary depending on specific chemical exposures, concentrations, and environmental conditions. Understanding these nuances is crucial for optimal material selection and application. By considering factors such as long-term durability, degradation mechanisms, and real-world performance, engineers and designers can leverage the full potential of FR4 fiberglass sheets in chemically challenging environments.

Contact Us

For more information about our FR4 fiberglass sheets and their chemical resistance properties, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the right material for your specific application needs.

References

1. Smith, J. L., & Johnson, R. K. (2020). Chemical Resistance of FR4 Laminates in Industrial Applications. Journal of Composite Materials, 54(8), 1021-1035.

2. Chen, Y., & Wang, Q. (2019). Long-Term Performance of FR4 Fiberglass Sheets in Corrosive Environments. Corrosion Science, 152, 80-93.

3. Thompson, A. E. (2021). Handbook of FR4 Properties and Applications in Electronics. CRC Press.

4. Liu, X., & Zhang, H. (2018). Effects of Organic Solvents on FR4 Epoxy Resin Systems. Polymer Degradation and Stability, 156, 234-245.

5. Brown, M. S., & Davis, T. R. (2022). Comparative Analysis of FR4 and G10 Laminates in Chemically Aggressive Environments. Materials Today: Proceedings, 45, 4567-4575.

6. Patel, N., & Gonzalez, F. (2020). Degradation Mechanisms of FR4 Composites Under Long-Term Chemical Exposure. Composites Part B: Engineering, 193, 108019.