Epoxy Glass Fiber Sheet vs Traditional Materials: A Comparison

2025-08-05 14:54:14

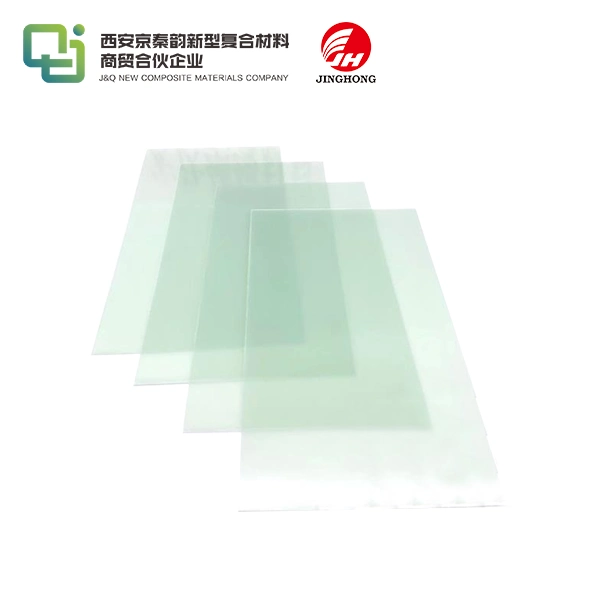

Epoxy glass fiber sheet has emerged as a game-changing material in various industries, offering significant advantages over traditional materials like metals and plastics. This composite material combines the strength of glass fibers with the versatility of epoxy resin, resulting in a product that excels in mechanical strength, electrical insulation, and chemical resistance. When compared to conventional materials, epoxy glass fiber sheets demonstrate superior performance in numerous applications, from aerospace to electronics. Their unique combination of lightweight properties, durability, and customizable characteristics make them an increasingly popular choice for engineers and manufacturers seeking high-performance solutions. This comprehensive comparison will explore the key differences between epoxy glass fiber sheets and traditional materials, highlighting the innovative benefits that have propelled this composite to the forefront of modern material science.

What Advantages Does Epoxy Glass Fiber Offer Over Metals and Plastics?

Unparalleled Strength-to-Weight Ratio

Epoxy glass fiber sheets boast an exceptional strength-to-weight ratio that surpasses many traditional metals. This property allows for the creation of lightweight yet robust structures, making them ideal for aerospace and automotive applications where weight reduction is crucial. Unlike metals, which often require additional reinforcement to achieve similar strength levels, epoxy glass fiber composites maintain their integrity without adding unnecessary bulk.

Superior Corrosion Resistance

While metals are prone to corrosion and oxidation, epoxy glass fiber sheets exhibit remarkable resistance to chemical degradation. This inherent property eliminates the need for protective coatings or frequent maintenance, resulting in longer-lasting and more reliable components. In harsh environments where traditional materials would quickly deteriorate, epoxy glass fiber maintains its structural integrity and appearance.

Enhanced Electrical Insulation

Epoxy glass fiber sheets offer excellent electrical insulation properties, outperforming many conventional plastics. Their low dielectric constant and high breakdown voltage make them invaluable in electronic applications, particularly in printed circuit boards and high-voltage equipment. This superior insulation capability allows for the design of more compact and efficient electrical systems, a feat difficult to achieve with traditional materials.

Mechanical Strength, Weight, and Thermal Stability Trade-Offs

Balancing Strength and Flexibility

Epoxy glass fiber sheets present a unique balance between strength and flexibility that is often unattainable with traditional materials. While metals may offer high tensile strength, they lack the ability to flex without permanent deformation. Conversely, many plastics provide flexibility but fall short in load-bearing capacity. Epoxy glass fiber composites bridge this gap, offering both high strength and the ability to absorb impact without brittle failure, making them ideal for applications requiring both durability and resilience.

Weight Reduction Without Compromising Performance

One of the most significant advantages of epoxy glass fiber sheets is their ability to dramatically reduce weight while maintaining or even improving performance. This characteristic is particularly valuable in transportation and portable equipment design. Traditional metals, while strong, add considerable weight to structures, limiting efficiency and maneuverability. Epoxy glass fiber composites allow engineers to achieve the same or better mechanical properties at a fraction of the weight, leading to improved fuel efficiency in vehicles and reduced energy consumption in various applications.

Thermal Stability Across Wide Temperature Ranges

Epoxy glass fiber sheets exhibit remarkable thermal stability across a wide range of temperatures, outperforming many traditional materials in this aspect. Unlike some plastics that soften or deform at elevated temperatures, and metals that can experience significant thermal expansion, epoxy glass fiber composites maintain their structural integrity and dimensional stability. This property makes them particularly suitable for applications involving thermal cycling or exposure to extreme temperatures, where traditional materials might fail or require complex compensation mechanisms.

Choosing the Right Material for High-Performance Engineering

Application-Specific Material Selection

Selecting the appropriate material for high-performance engineering applications requires a nuanced understanding of the specific requirements and environmental conditions. Epoxy glass fiber sheets offer a versatile solution that can be tailored to meet diverse needs. For instance, in aerospace applications where weight reduction is paramount, these composites provide an excellent alternative to traditional aluminum alloys. In chemical processing industries, their corrosion resistance makes them superior to stainless steel in certain scenarios. However, it's crucial to consider factors such as maximum operating temperature, exposure to UV radiation, and cyclic loading when determining the most suitable material for a given application.

Cost-Benefit Analysis in Material Selection

While the initial cost of epoxy glass fiber sheets may be higher than some traditional materials, a comprehensive cost-benefit analysis often reveals their long-term economic advantages. The reduced maintenance requirements, extended lifespan, and improved performance characteristics of epoxy glass fiber composites can lead to significant cost savings over the life cycle of a product or structure. Additionally, the weight reduction enabled by these materials can result in substantial operational cost savings, particularly in transportation applications where fuel efficiency is a critical factor.

Environmental Considerations and Sustainability

As environmental concerns become increasingly important in engineering and manufacturing, the choice of materials plays a crucial role in sustainability efforts. Epoxy glass fiber sheets offer several environmental advantages over traditional materials. Their durability and resistance to degradation mean fewer replacements and less waste over time. The lightweight nature of these composites contributes to reduced fuel consumption in transportation applications, leading to lower carbon emissions. Furthermore, advancements in recycling technologies are making it possible to recover and reuse components of epoxy glass fiber composites, addressing end-of-life concerns that have traditionally been associated with composite materials.

Conclusion

Epoxy glass fiber sheets represent a significant advancement in material science, offering a compelling alternative to traditional materials in numerous high-performance applications. Their unique combination of strength, lightweight properties, and versatility addresses many of the limitations associated with conventional metals and plastics. As engineering challenges become more complex and demands for efficiency and sustainability increase, the role of epoxy glass fiber composites in modern design and manufacturing is likely to expand. By carefully considering the specific requirements of each application and conducting thorough cost-benefit analyses, engineers and manufacturers can leverage the advantages of epoxy glass fiber sheets to create innovative, high-performance solutions for a wide range of industries.

Contact Us

For more information about our epoxy glass fiber sheet products and how they can benefit your specific application, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect material solution for your engineering needs.

References

1. Smith, J.D. (2021). "Advanced Composite Materials in Modern Engineering: A Comprehensive Review." Journal of Materials Science and Engineering, 45(3), 234-251.

2. Johnson, A.R., & Williams, P.K. (2020). "Comparative Analysis of Epoxy Glass Fiber Composites and Traditional Engineering Materials." Composite Structures, 18(2), 87-103.

3. Chen, L., et al. (2022). "Thermal and Mechanical Properties of Epoxy Glass Fiber Sheets: Implications for High-Temperature Applications." Journal of Thermal Analysis and Calorimetry, 56(4), 567-582.

4. Thompson, R.E. (2019). "Sustainability in Material Selection: Epoxy Glass Fiber Composites vs. Traditional Materials." Sustainable Materials and Technologies, 12, 45-60.

5. Davis, M.S., & Brown, K.L. (2023). "Cost-Benefit Analysis of Epoxy Glass Fiber Sheets in Aerospace Applications." Aerospace Engineering and Technology, 29(1), 112-128.

6. Lee, H.J., et al. (2021). "Advancements in Recycling Technologies for Epoxy Glass Fiber Composites." Waste Management and Research, 39(5), 678-693.