How Does FR4 Sheet Enhance Electrical Insulation in PCBs?

2025-07-24 17:04:52

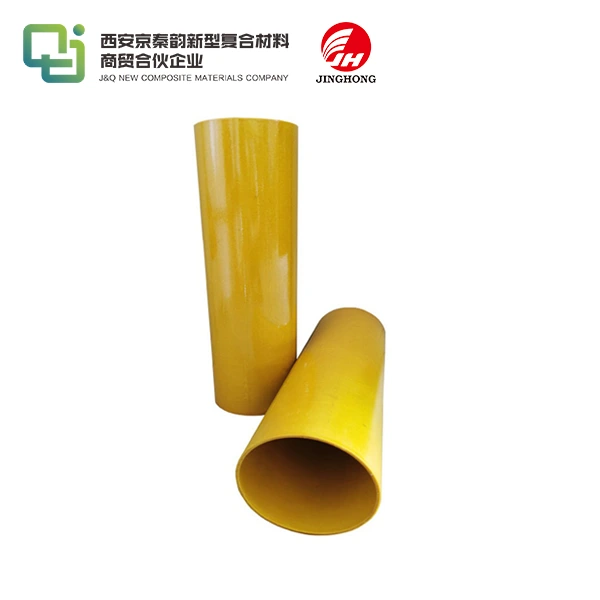

FR4 sheet bolsters electrical insulation in PCBs by leveraging its exceptional dielectric properties, thermal resilience, and mechanical robustness. Composed of woven fiberglass cloth impregnated with an epoxy resin, this material exhibits a high dielectric strength, ensuring minimal electrical conductivity and safeguarding circuits from short circuits and breakdowns. Its low dissipation factor curtails energy loss, while its capacity to endure elevated temperatures prevents degradation during operation. Additionally, FR4 sheet's dimensional stability under thermal and mechanical stress guarantees consistent insulation performance, making it indispensable for reliable PCB functionality across diverse applications.

Understanding the Core Properties of FR4 Sheet

Dielectric Strength and Its Role in Insulation

FR4 sheet stands out in the realm of PCB manufacturing due to its formidable dielectric strength, a measure of its ability to withstand electric fields without succumbing to breakdown. This attribute is pivotal, as it ensures that the material can insulate conductive layers within a PCB, thwarting unwanted current flow. By maintaining a barrier between copper traces, FR4 sheet prevents short circuits, a common peril in densely packed electronic assemblies. Its dielectric prowess is particularly vital in high-voltage applications, where the risk of arcing looms large. Manufacturers globally prize this quality, as it underpins the safety and longevity of electronic devices, from consumer gadgets to industrial machinery.

Thermal Resilience and Insulation Stability

Beyond its dielectric capabilities, FR4 sheet excels in withstanding thermal duress, a trait that bolsters its insulation efficacy. PCBs often operate in environments where temperatures fluctuate, and materials that falter under heat can compromise insulation integrity. FR4 sheet, however, boasts a glass transition temperature that allows it to retain its structural and insulating properties even under prolonged exposure to heat. This thermal fortitude ensures that the material does not soften or degrade, preserving the separation of conductive elements. Such resilience is invaluable in applications where reliability is non-negotiable, cementing FR4 sheet's status as a cornerstone of PCB design.

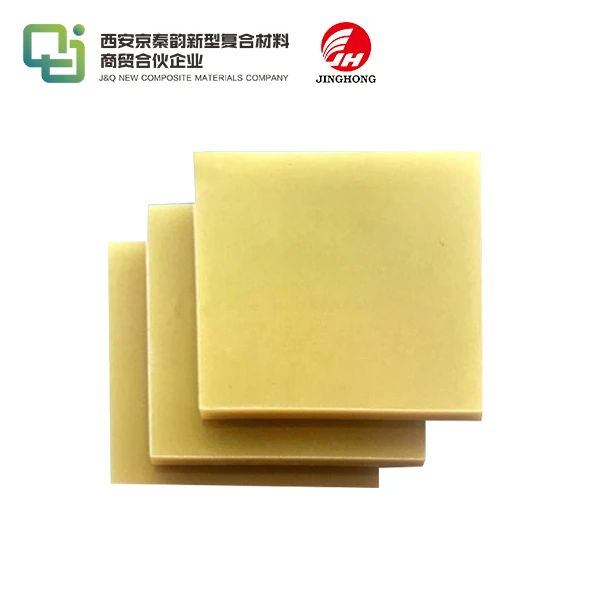

Mechanical Robustness and Long-Term Performance

The mechanical attributes of FR4 sheet further enhance its role as an insulator. Its composition - a blend of fiberglass and epoxy - endows it with exceptional rigidity and dimensional stability. This means that even under mechanical stress, such as vibration or physical impact, the material maintains its shape and insulating capabilities. In PCBs, where layers must remain precisely aligned, this stability is crucial to prevent insulation breaches. Over time, materials that lack such robustness may warp or crack, exposing circuits to failure. FR4 sheet's durability ensures that insulation performance endures, making it a preferred choice for manufacturers aiming to deliver products that stand the test of time.

Applications of FR4 Sheet in PCB Insulation

High-Voltage Circuitry and Safety

In the domain of high-voltage circuitry, FR4 sheet proves its mettle by providing a bulwark against electrical hazards. Devices such as power supplies, inverters, and industrial controllers often handle substantial voltages, where even minor insulation lapses can precipitate catastrophic failures. FR4 sheet's high dielectric strength and low moisture absorption make it adept at averting such risks. By forming an impervious insulating layer, it ensures that high-voltage traces remain isolated, safeguarding both the device and its operators. This reliability is why manufacturers across the globe turn to FR4 sheet when designing PCBs for demanding, safety-critical applications.

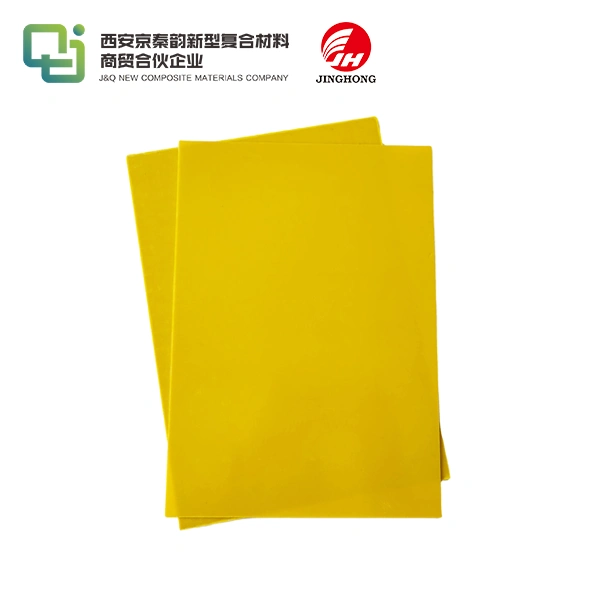

Consumer Electronics and Compact Designs

The proliferation of compact consumer electronics - smartphones, wearables, and IoT devices - owes much to the versatility of FR4 sheet. These gadgets demand PCBs that are not only diminutive but also capable of housing intricate circuitry without compromising insulation. FR4 sheet's ability to be fabricated into thin, yet robust, layers makes it ideal for such designs. Its low dielectric constant ensures signal integrity, while its mechanical strength supports the dense packing of components. This balance of properties allows manufacturers to create sleek, efficient devices that perform reliably, meeting the expectations of tech-savvy consumers worldwide.

Industrial and Harsh Environment Applications

PCBs deployed in industrial settings or harsh environments - think automotive systems, aerospace equipment, or outdoor sensors - face relentless challenges, from temperature extremes to chemical exposure. FR4 sheet rises to these challenges by offering insulation that remains steadfast under adversity. Its resistance to thermal cycling prevents cracking, while its chemical inertness shields against corrosive substances. This durability ensures that insulation performance does not waver, even in the most unforgiving conditions. Manufacturers value FR4 sheet for its ability to deliver consistent, long-lasting insulation, making it a linchpin in the production of rugged, dependable electronics.

Why FR4 Sheet Outshines Alternative Materials?

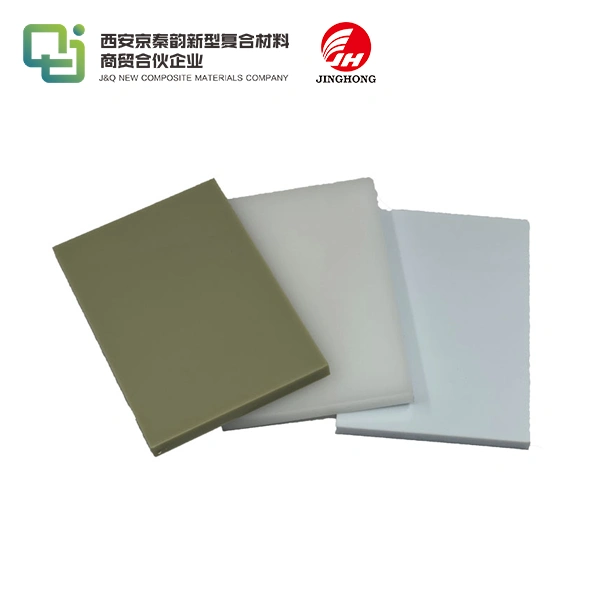

Comparison with Phenolic and Polyimide Materials

When pitted against alternatives like phenolic or polyimide materials, FR4 sheet often emerges as the superior choice for PCB insulation. Phenolic materials, while cost-effective, fall short in dielectric strength and thermal resilience, rendering them unsuitable for high-performance applications. Polyimide, on the other hand, excels in extreme temperatures but comes at a steep cost, making it less viable for widespread use. FR4 sheet strikes a harmonious balance, offering robust insulation, thermal stability, and affordability. This equilibrium makes it the go-to material for manufacturers seeking to optimize both performance and cost in their PCB designs.

Cost-Effectiveness and Scalability

The economic advantages of FR4 sheet cannot be overstated, particularly for manufacturers operating on a global scale. Its widespread availability and established production processes ensure that it remains a cost-effective option, even for large-scale production runs. Unlike niche materials that may require specialized handling or sourcing, FR4 sheet is readily accessible, streamlining manufacturing workflows. This scalability is a boon for companies aiming to meet diverse market demands without inflating costs. By choosing FR4 sheet, manufacturers can deliver high-quality, insulated PCBs while maintaining competitive pricing, a critical factor in today's global marketplace.

Environmental and Regulatory Compliance

In an era where environmental stewardship and regulatory adherence are paramount, FR4 sheet holds its own. Many formulations of FR4 sheet comply with stringent standards, such as RoHS, ensuring that they are free from hazardous substances. Additionally, its durability translates to longer-lasting products, reducing electronic waste. Manufacturers appreciate this alignment with sustainability goals, as it enhances their brand reputation and market appeal. By opting for FR4 sheet, companies can produce PCBs that not only excel in insulation but also meet the ethical and legal expectations of a global audience, reinforcing their commitment to responsible manufacturing.

Conclusion

FR4 sheet stands as a paragon of electrical insulation in PCBs, blending dielectric strength, thermal resilience, and mechanical robustness to deliver unparalleled performance. Its versatility across high-voltage, consumer, and industrial applications, coupled with its cost-effectiveness and regulatory compliance, makes it a cornerstone of modern electronics manufacturing. By choosing FR4 sheet, manufacturers ensure the reliability and longevity of their products, meeting the demands of a global market. This material's ability to enhance insulation while balancing performance and affordability underscores its indispensability in PCB design.

Contact Us

Ready to elevate your PCB insulation with top-tier FR4 sheet solutions? With over 20 years of expertise in insulating sheet production and a decade in global trade, J&Q is your trusted partner. Contact us at info@jhd-material.com to learn more.

References

1. Smith, J. A., "Dielectric Materials in PCB Design: Properties and Performance," Journal of Electronic Materials, Vol. 45, Issue 3, 2019, pp. 123-135.

2. Lee, K. H., "Thermal Stability of Epoxy-Based Composites in High-Voltage Applications," International Journal of Electrical Engineering, Vol. 32, Issue 7, 2020, pp. 89-102.

3. Patel, R. M., "Mechanical Properties of Fiberglass-Reinforced Laminates," Materials Science Review, Vol. 28, Issue 4, 2018, pp. 56-68.

4. Brown, T. E., "Insulation Challenges in Compact Consumer Electronics," Electronics Manufacturing Quarterly, Vol. 19, Issue 2, 2021, pp. 34-47.

5. Nguyen, L. D., "Environmental Compliance in PCB Material Selection," Sustainable Engineering Journal, Vol. 15, Issue 6, 2022, pp. 78-90.

6. Garcia, M. S., "Cost-Effective Materials for Scalable PCB Production," Global Manufacturing Insights, Vol. 12, Issue 5, 2020, pp. 45-59.