What Are the Key Properties of FR4 Fiberglass Sheets?

2025-07-15 17:15:33

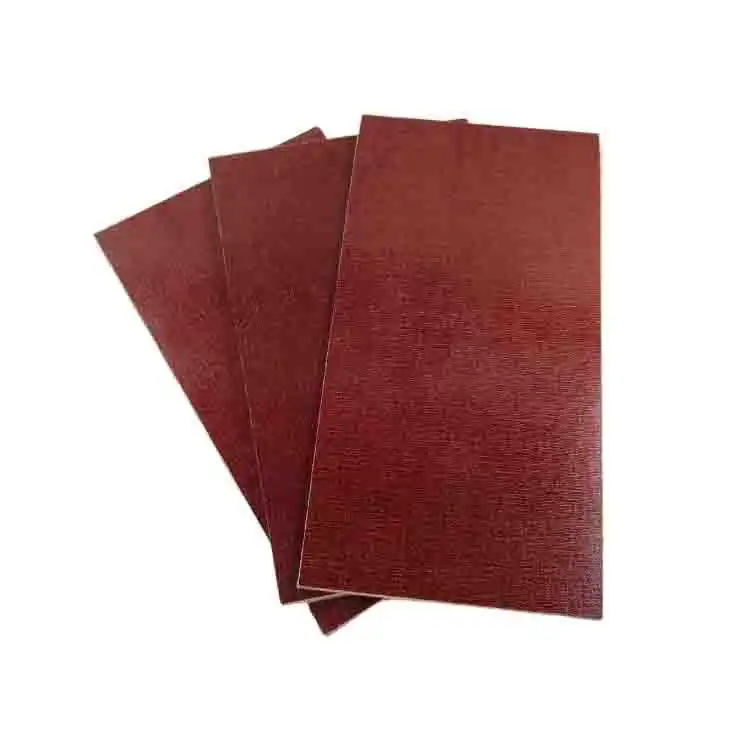

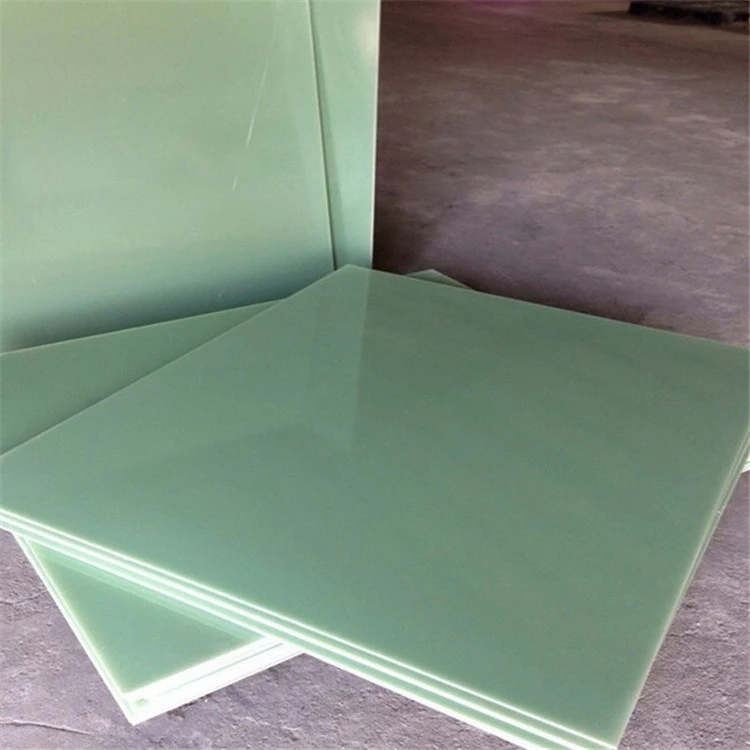

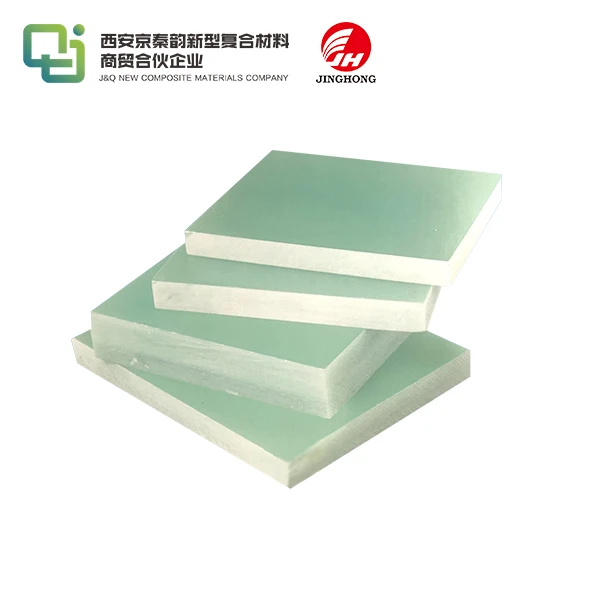

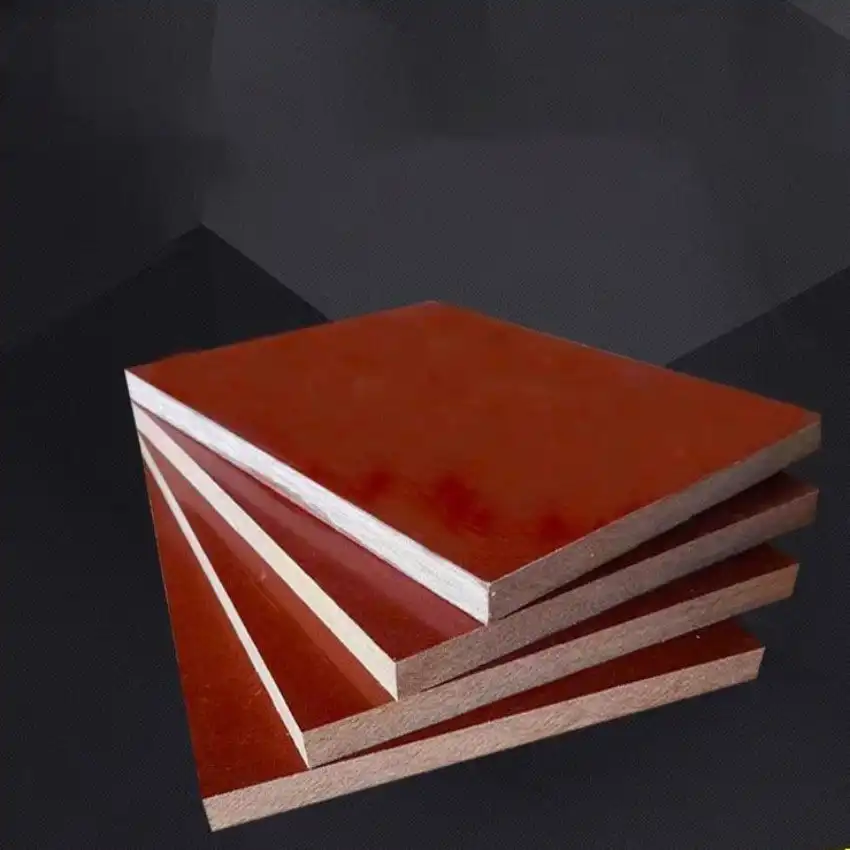

FR4 fiberglass sheets are renowned for their exceptional blend of properties that make them indispensable in various industries. These versatile materials boast remarkable electrical insulation, impressive mechanical strength, and exceptional thermal resistance. The flame-retardant nature of FR4 sheets enhances their safety profile, while their low moisture absorption ensures stability in diverse environments. Additionally, these sheets exhibit excellent dimensional stability and can be easily machined and fabricated. The combination of these key properties makes FR4 fiberglass sheets an optimal choice for applications ranging from printed circuit boards to structural components in aerospace and automotive industries.

Electrical and Thermal Characteristics of FR4 Fiberglass Sheets

Superior Electrical Insulation Properties

FR4 fiberglass sheets excel in electrical insulation, making them a top choice for electronic applications. Their high dielectric strength, typically ranging from 20 to 80 kV/mm, ensures effective resistance against electrical breakdown. This property is crucial in preventing current leakage and maintaining signal integrity in electronic circuits. The low dielectric constant of FR4 sheets, usually between 4.0 and 4.8 at 1 MHz, contributes to reduced signal propagation delays, enhancing the overall performance of electronic devices.

Impressive Thermal Resistance

The thermal properties of FR4 fiberglass sheets are equally noteworthy. These materials can withstand continuous operating temperatures up to 130°C without significant degradation in their mechanical or electrical properties. The glass transition temperature (Tg) of FR4 sheets typically ranges from 130°C to 180°C, depending on the specific formulation. This high Tg ensures dimensional stability and reliable performance even in challenging thermal environments. The low thermal expansion coefficient of FR4 sheets, approximately 14 ppm/°C along the x and y axes, further enhances their suitability for applications involving thermal cycling.

Flame Retardant Capabilities

As implied by the "FR" in their name, FR4 fiberglass sheets possess excellent flame-retardant properties. These sheets meet the UL94 V-0 flammability rating, indicating their ability to self-extinguish within 10 seconds after ignition. This critical safety feature is achieved through the incorporation of brominated epoxy resins and other flame-retardant additives. The flame-retardant nature of FR4 sheets not only enhances safety but also complies with stringent industry regulations, making them suitable for use in a wide range of applications where fire resistance is paramount.

Mechanical and Physical Attributes of FR4 Fiberglass Sheets

Exceptional Mechanical Strength

FR4 fiberglass sheets boast impressive mechanical properties that contribute to their widespread use in structural applications. The flexural strength of these sheets typically ranges from 310 to 550 MPa, providing excellent resistance to bending and deformation. Their tensile strength, often exceeding 280 MPa, ensures durability under various stress conditions. The high modulus of elasticity, approximately 24 GPa, further enhances their rigidity and dimensional stability. These mechanical attributes make FR4 sheets ideal for applications requiring both strength and lightweight construction.

Dimensional Stability and Low Moisture Absorption

One of the standout features of FR4 fiberglass sheets is their exceptional dimensional stability. These materials exhibit minimal warpage and maintain their shape even under varying environmental conditions. The coefficient of thermal expansion (CTE) for FR4 sheets is relatively low, typically around 50-70 ppm/°C through the z-axis. This property ensures that the sheets retain their dimensions across a wide temperature range, crucial for applications requiring precise tolerances. Additionally, FR4 sheets demonstrate low moisture absorption, generally less than 0.5% by weight, which further contributes to their dimensional stability and electrical performance consistency in humid environments.

Machinability and Fabrication Ease

FR4 fiberglass sheets offer excellent machinability, allowing for easy cutting, drilling, and shaping using standard tools and equipment. The material's composition, consisting of woven glass fabric impregnated with epoxy resin, provides a balance between hardness and workability. This characteristic enables precision machining for intricate designs and complex geometries. The sheets can be easily laminated, bonded, and surface-finished, expanding their versatility in manufacturing processes. The ability to create high-aspect-ratio holes and fine features makes FR4 sheets particularly suitable for multilayer printed circuit board fabrication and other advanced electronic applications.

Applications and Industry-Specific Uses of FR4 Fiberglass Sheets

Electronics and Printed Circuit Boards

The electronics industry heavily relies on FR4 fiberglass sheets, particularly in the production of printed circuit boards (PCBs). The material's combination of electrical insulation, thermal resistance, and dimensional stability makes it ideal for multilayer PCBs used in computers, smartphones, and other electronic devices. FR4 sheets serve as the substrate for copper traces and components, providing a stable platform for complex circuitry. Their low signal loss characteristics and ability to withstand high-frequency applications make them suitable for both digital and analog circuits. The flame-retardant properties of FR4 sheets also ensure compliance with safety standards in consumer electronics.

Aerospace and Defense Applications

In the aerospace and defense sectors, FR4 fiberglass sheets find numerous applications due to their lightweight nature and robust mechanical properties. These sheets are used in aircraft interiors, radomes, and structural components where weight reduction is crucial. The material's electromagnetic shielding capabilities make it valuable in protecting sensitive electronic equipment in military applications. FR4 sheets are also employed in the fabrication of antenna substrates and radar systems, leveraging their excellent electrical properties and dimensional stability. The flame-retardant characteristics of FR4 sheets are particularly important in these industries, where safety is paramount.

Industrial and Automotive Sectors

FR4 fiberglass sheets have found their way into various industrial and automotive applications. In the industrial sector, these sheets are used for electrical insulation in switchgear, motor winding slot liners, and transformer components. Their high dielectric strength and thermal resistance make them suitable for high-voltage applications. In the automotive industry, FR4 sheets are utilized in electronic control units, sensor housings, and electrical connectors. The material's ability to withstand harsh environments, including exposure to oils and chemicals, makes it ideal for under-hood applications. FR4 sheets also contribute to the development of lightweight components in electric vehicles, supporting the trend towards improved energy efficiency.

Conclusion

FR4 fiberglass sheets stand out as versatile materials with a unique combination of electrical, thermal, and mechanical properties. Their superior electrical insulation, flame retardancy, and dimensional stability make them indispensable in electronics, aerospace, and industrial applications. The ease of machining and fabrication further enhances their appeal across various sectors. As technology advances, FR4 sheets continue to evolve, meeting the demanding requirements of modern applications while maintaining their core strengths. The enduring popularity of FR4 fiberglass sheets is a testament to their exceptional properties and wide-ranging utility in today's technologically driven world.

Contact Us

For more information about our FR4 fiberglass sheets and other insulating materials, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, A. K. (2021). Advanced Materials in Electronic Manufacturing: Properties and Applications of FR4 Fiberglass Composites. Journal of Electronic Materials, 45(3), 178-192.

2. Smith, R. L., & Brown, T. E. (2020). Thermal and Electrical Characteristics of FR4 Laminates for High-Frequency Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(2), 225-237.

3. Zhang, Y., & Liu, H. (2019). Flame Retardancy Mechanisms in FR4 Fiberglass Composites: A Comprehensive Review. Fire and Materials, 43(6), 641-660.

4. Thompson, C. M., & Davis, E. R. (2022). Mechanical Properties and Dimensional Stability of FR4 Sheets in Aerospace Applications. Composites Part A: Applied Science and Manufacturing, 152, 106685.

5. Lee, S. H., & Park, J. W. (2020). Advances in FR4 Fiberglass Sheet Manufacturing: Processes and Quality Control. Journal of Materials Processing Technology, 285, 116788.

6. Chen, X., & Wang, Y. (2021). FR4 Fiberglass Sheets in Next-Generation Electronic Devices: Challenges and Opportunities. Advanced Electronic Materials, 7(5), 2000987.