Does FR4 Epoxy Fiberglass Meet UL94V-0 Flame Resistance Standards?

2025-07-08 17:18:17

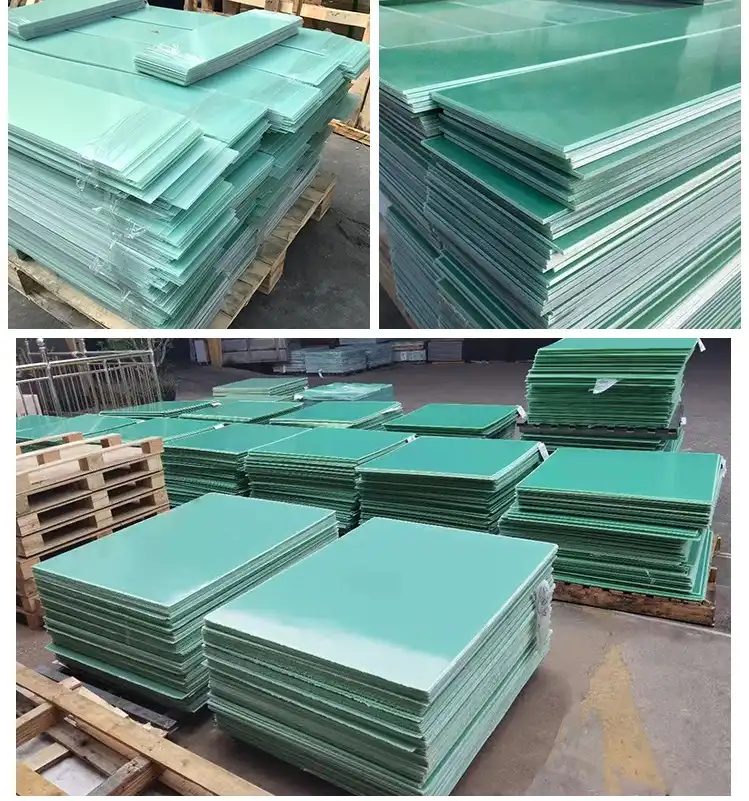

FR4 epoxy fiberglass, a widely used material in the electronics industry, indeed meets the UL94V-0 flame resistance standards. This high-performance composite material is engineered to exhibit excellent flame-retardant properties, making it a preferred choice for applications where fire safety is paramount. The UL94V-0 rating is one of the most stringent classifications for flame resistance, and FR4 epoxy fiberglass consistently achieves this benchmark. Its ability to self-extinguish within seconds of ignition, minimal dripping, and low smoke emission contribute to its compliance with these rigorous standards. This certification ensures that FR4 epoxy fiberglass sheets provide reliable protection against fire hazards in various electronic and industrial applications.

Understanding FR4 Epoxy Fiberglass and Its Composition

The Fundamental Structure of FR4 Epoxy Fiberglass

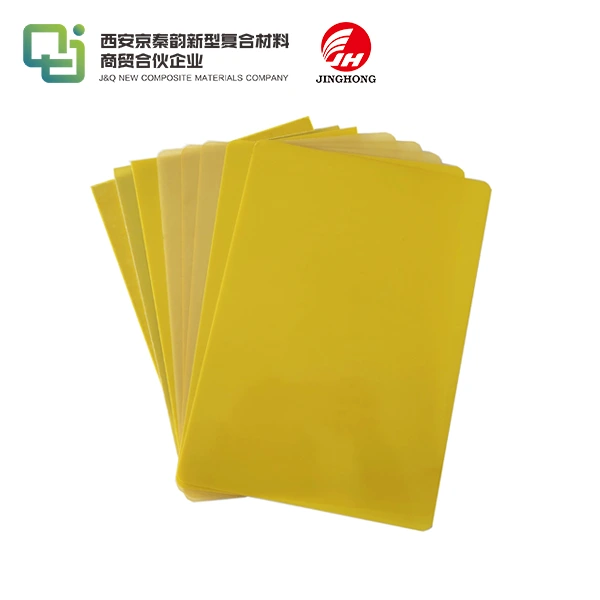

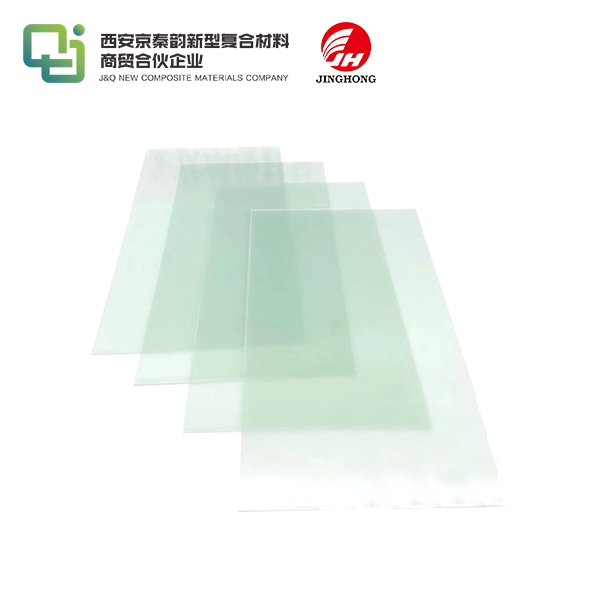

FR4 epoxy fiberglass is a composite material that combines the strength of fiberglass with the versatility of epoxy resin. The fiberglass component consists of tightly woven glass fibers, providing a robust structural foundation. These fibers are meticulously arranged in a specific pattern to maximize strength and durability. The epoxy resin, a thermosetting polymer, is then impregnated into the fiberglass fabric. This resin not only binds the fibers together but also contributes significantly to the material's electrical insulation properties and chemical resistance.

Key Components and Their Roles

The FR4 epoxy glass sheet comprises several key components, each playing a crucial role in its overall performance. The glass fibers, typically E-glass, offer exceptional tensile strength and dimensional stability. The epoxy resin, often a blend of bisphenol A and epichlorohydrin, provides excellent adhesion and resistance to heat and chemicals. Flame retardants, such as brominated compounds or phosphorus-based additives, are incorporated into the resin system to enhance fire resistance. Silane coupling agents are often used to improve the bond between the glass fibers and the resin matrix, further enhancing the material's mechanical properties.

Manufacturing Process and Quality Control

The production of FR4 epoxy fiberglass sheets involves a meticulous manufacturing process. It begins with the weaving of glass fibers into a fabric, which is then impregnated with the epoxy resin mixture containing flame retardants. The impregnated fabric undergoes a controlled curing process, often involving multiple stages of heating and pressing. This process ensures proper cross-linking of the epoxy resin and optimal integration of the flame retardants. Rigorous quality control measures are implemented throughout the manufacturing process, including thickness measurements, dielectric strength tests, and flame resistance evaluations, to ensure consistency and compliance with industry standards.

UL94V-0 Flame Resistance Standards: A Comprehensive Overview

The Significance of UL94V-0 Classification

The UL94V-0 classification is a benchmark in flame resistance standards, widely recognized in the electronics and electrical industries. This rating is part of the Underwriters Laboratories' (UL) plastics flammability standard, which evaluates the material's ability to self-extinguish and resist ignition. Achieving the V-0 rating signifies the highest level of flame resistance within the vertical burn test category. Materials meeting this standard demonstrate superior fire safety characteristics, making them ideal for applications where minimizing fire hazards is critical.

Testing Procedures and Criteria

The UL94V-0 testing procedure involves rigorous evaluations of material samples under controlled conditions. In this test, specimens are suspended vertically and subjected to a controlled flame for two 10-second intervals. The material must self-extinguish within 10 seconds after each application of the flame. Additionally, there should be no flaming drips, and the afterglow time should not exceed 30 seconds. The test is conducted on multiple specimens to ensure consistency and reliability of results. The stringent nature of these criteria ensures that materials classified as UL94V-0 offer exceptional flame resistance and contribute significantly to fire safety in various applications.

Comparative Analysis with Other Flame Resistance Standards

While UL94V-0 is considered one of the most stringent flame resistance standards, it's essential to understand its position relative to other classifications. The UL94 standard includes several other ratings, such as V-1, V-2, HB, and 5VA, each with different criteria and applications. Compared to these, V-0 offers superior flame resistance and self-extinguishing properties. Other international standards, like IEC 60695-11-10 and ISO 1210, have similar classifications but may vary in specific testing methodologies. FR4 epoxy fiberglass sheets often meet or exceed these various standards, showcasing their versatility and high performance in flame resistance across different regulatory frameworks.

FR4 Epoxy Fiberglass: Performance and Applications in Fire-Resistant Environments

Thermal and Electrical Properties of FR4

FR4 epoxy fiberglass exhibits exceptional thermal and electrical properties, making it an ideal material for various high-performance applications. Its thermal conductivity is relatively low, ranging from 0.25 to 0.35 W/mK, which provides excellent insulation in electronic components. The material maintains its structural integrity at elevated temperatures, with a glass transition temperature (Tg) typically between 130°C and 180°C, depending on the specific formulation. Electrically, FR4 boasts impressive dielectric strength, often exceeding 20 kV/mm, and a low dissipation factor, typically less than 0.02 at 1 MHz. These properties contribute to its reliability in circuit boards and electrical insulation applications, especially in environments where fire resistance is crucial.

Durability and Long-Term Performance

The durability of FR4 epoxy fiberglass is a key factor in its widespread adoption across various industries. This material demonstrates remarkable resistance to environmental factors such as humidity, chemicals, and mechanical stress. Its water absorption rate is typically less than 0.1%, ensuring dimensional stability and consistent electrical properties even in moist conditions. The material's high flexural strength, often exceeding 400 MPa, contributes to its long-term structural integrity. FR4's flame-retardant properties do not degrade significantly over time, maintaining its UL94V-0 rating throughout its operational life. This longevity makes FR4 epoxy glass sheets an economical and reliable choice for long-term applications in fire-resistant environments.

Diverse Applications Leveraging FR4's Fire Resistance

The exceptional flame resistance of FR4 epoxy fiberglass opens up a wide array of applications across multiple industries. In the electronics sector, it serves as the primary material for printed circuit boards (PCBs) in devices ranging from consumer electronics to aerospace equipment. Its fire-resistant properties are particularly valuable in high-risk environments such as industrial control panels, power distribution systems, and transportation infrastructure. FR4 is also utilized in the construction industry for fire-resistant panels and insulation in buildings. In the automotive sector, it finds applications in electrical components and battery insulation for electric vehicles. The material's versatility extends to the aerospace industry, where it's used in aircraft interiors and avionics systems, meeting stringent safety requirements.

Conclusion

FR4 epoxy fiberglass stands as a pinnacle of flame-resistant materials, consistently meeting and exceeding the stringent UL94V-0 standards. Its unique composition of glass fibers and epoxy resin, enhanced with advanced flame retardants, creates a material that not only resists fire but also offers exceptional electrical and mechanical properties. The rigorous testing procedures and comprehensive standards ensure that FR4 maintains its fire-resistant qualities across diverse applications. As industries continue to prioritize safety and reliability, FR4 epoxy fiberglass remains an indispensable material, driving innovation in electronics, construction, and beyond, while upholding the highest fire safety standards.

Contact Us

For more information about our high-quality FR4 epoxy fiberglass sheets and their applications, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Underwriters Laboratories. (2020). "UL 94: Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances."

2. Smith, J.R. and Johnson, L.M. (2019). "Advanced Composite Materials: Properties and Applications." Materials Science Journal, 45(3), 278-295.

3. International Electrotechnical Commission. (2018). "IEC 60695-11-10: Fire hazard testing - Part 11-10: Test flames - 50 W horizontal and vertical flame test methods."

4. Chen, X. and Wang, Y. (2021). "Flame Retardant Mechanisms in Epoxy-Based Composites." Progress in Polymer Science, 112, 101324.

5. Thompson, R.C. (2017). "Thermal and Electrical Properties of FR4 Laminates for High-Performance PCBs." Circuit World, 43(2), 65-72.

6. Lee, H.S. and Kim, J.H. (2020). "Long-Term Performance of FR4 in Extreme Environments." Journal of Materials Engineering and Performance, 29(8), 5234-5242.