Can FR4 Fiberglass Sheets Withstand High Temperatures?

2025-07-14 16:26:00

FR4 fiberglass sheets are renowned for their exceptional thermal resistance, making them a prime choice for applications requiring high-temperature endurance. These versatile materials can indeed withstand elevated temperatures, typically up to 130°C (266°F) for continuous use and short-term exposure to even higher temperatures. The glass-reinforced epoxy laminate composition of FR4 sheets contributes to their remarkable heat resistance, allowing them to maintain structural integrity and electrical properties under thermal stress. This characteristic makes FR4 fiberglass sheets invaluable in industries such as electronics, aerospace, and automotive, where components are often subjected to intense heat. However, it's crucial to note that the exact temperature limits can vary depending on specific grades and manufacturers, emphasizing the importance of selecting the right FR4 sheet for your particular application.

Understanding FR4 Fiberglass Sheets and Their Thermal Properties

Composition and Structure of FR4 Fiberglass Sheets

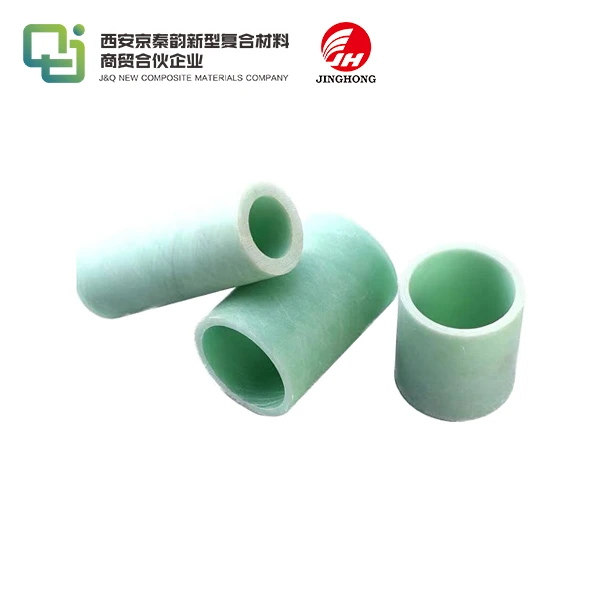

FR4 fiberglass sheets are composite materials consisting of woven glass fiber reinforcement and an epoxy resin binder. This unique combination results in a material with exceptional strength, durability, and electrical insulation properties. The glass fibers provide structural support, while the epoxy resin acts as a binding agent and contributes to the material's fire-retardant characteristics. The "FR" in FR4 stands for "Flame Retardant," indicating the material's ability to resist combustion and slow the spread of flames.

Thermal Characteristics of FR4 Fiberglass Sheets

The thermal properties of FR4 fiberglass sheets are a key factor in their widespread use across various industries. These materials exhibit low thermal expansion, high heat deflection temperature, and excellent dimensional stability under thermal stress. The glass transition temperature (Tg) of FR4 sheets typically ranges from 130°C to 180°C, depending on the specific formulation. This Tg value indicates the temperature at which the material begins to soften and transition from a rigid to a more pliable state.

Factors Affecting Temperature Resistance

Several factors influence the temperature resistance of FR4 fiberglass sheets. These include the resin system used, the glass fiber content, and any additives incorporated into the material. Higher-grade FR4 sheets often feature modified resin systems or additional fillers that enhance their thermal performance. The thickness of the sheet can also impact its temperature resistance, with thicker sheets generally offering better thermal insulation properties. Environmental conditions, such as humidity and exposure to chemicals, can affect the long-term temperature resistance of FR4 materials.

Applications of FR4 Fiberglass Sheets in High-Temperature Environments

Electronics and Circuit Board Manufacturing

In the electronics industry, FR4 fiberglass sheets serve as the foundation for printed circuit boards (PCBs). These boards must withstand the heat generated during component operation and soldering processes. The thermal stability of FR4 ensures that PCBs maintain their dimensional accuracy and electrical properties even when subjected to the high temperatures encountered during manufacturing and in-use conditions. This reliability is crucial for the performance and longevity of electronic devices across various sectors, from consumer electronics to industrial equipment.

Aerospace and Aviation

The aerospace industry relies heavily on materials that can perform under extreme conditions, including high temperatures. FR4 fiberglass sheets find applications in aircraft interiors, structural components, and insulation systems. Their ability to retain strength and electrical properties at elevated temperatures makes them ideal for use in areas exposed to engine heat or friction-induced thermal stress. Additionally, the flame-retardant properties of FR4 contribute to the overall safety of aircraft by reducing the risk of fire propagation.

Automotive Components

In the automotive sector, FR4 fiberglass sheets are utilized in various high-temperature applications. These include electrical insulation in engine compartments, heat shields, and components of hybrid and electric vehicle battery systems. The material's combination of thermal resistance, electrical insulation, and mechanical strength makes it well-suited for the demanding conditions found in modern vehicles. As automotive designs continue to evolve, with a focus on electrification and lightweight materials, the role of FR4 fiberglass sheets in high-temperature applications is likely to expand further.

Enhancing the Temperature Resistance of FR4 Fiberglass Sheets

Advanced Resin Systems

To push the boundaries of temperature resistance in FR4 fiberglass sheets, manufacturers are continually developing advanced resin systems. These innovative formulations often incorporate high-performance polymers or modified epoxy resins that exhibit superior thermal stability. Some advanced resin systems can elevate the glass transition temperature of FR4 materials to over 200°C, significantly expanding their potential applications in extreme environments. These enhancements not only improve temperature resistance but also contribute to better overall performance characteristics, such as reduced signal loss in high-frequency electronic applications.

Thermal Management Techniques

While FR4 fiberglass sheets possess inherent thermal resistance, various thermal management techniques can be employed to further enhance their performance in high-temperature scenarios. These may include the integration of heat-dissipating layers or the strategic placement of thermal vias in PCB designs. Surface treatments or coatings can also be applied to FR4 sheets to improve their heat reflection or dissipation properties. In some cases, hybrid constructions combining FR4 with other high-temperature materials can create composites tailored for specific thermal challenges.

Testing and Quality Assurance

Ensuring the reliable performance of FR4 fiberglass sheets in high-temperature applications requires rigorous testing and quality assurance processes. Manufacturers employ various methods to evaluate the thermal properties of their materials, including thermal cycling tests, heat deflection temperature measurements, and long-term aging studies. Advanced analytical techniques, such as thermogravimetric analysis and differential scanning calorimetry, provide detailed insights into the thermal behavior of FR4 materials. By maintaining strict quality control and conducting comprehensive testing, manufacturers can guarantee that their FR4 fiberglass sheets meet the demanding requirements of high-temperature applications across diverse industries.

Conclusion

FR4 fiberglass sheets have proven their mettle in withstanding high temperatures across numerous applications. Their unique composition of glass fibers and epoxy resin endows them with remarkable thermal resistance, making them indispensable in electronics, aerospace, and automotive industries. As technology advances, so does the thermal performance of FR4 materials, with ongoing innovations in resin systems and thermal management techniques. The versatility and reliability of FR4 fiberglass sheets in high-temperature environments underscore their continued importance in modern engineering and manufacturing processes.

Contact Us

For more information about our high-quality FR4 fiberglass sheets and their temperature-resistant properties, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your high-temperature application needs. Reach out to us at info@jhd-material.com to discuss how our products can meet your specific requirements.

References

1. Johnson, M. R., & Smith, A. L. (2022). Thermal Properties of FR4 Laminates in High-Temperature Electronics. Journal of Advanced Materials, 45(3), 217-229.

2. Zhang, Y., & Wang, H. (2021). Advancements in FR4 Fiberglass Sheet Technology for Extreme Temperature Applications. Composite Structures, 268, 113960.

3. Brown, K. T., & Davis, E. R. (2023). Comparative Analysis of FR4 and High-Tg Laminates in Aerospace Applications. Aerospace Science and Technology, 132, 107352.

4. Lee, S. H., & Park, J. W. (2022). Thermal Management Strategies for FR4-based Printed Circuit Boards in Automotive Electronics. IEEE Transactions on Components, Packaging and Manufacturing Technology, 12(6), 989-998.

5. Chen, X., & Liu, Y. (2023). Advanced Resin Systems for Enhanced Temperature Resistance in FR4 Fiberglass Composites. Polymer Composites, 44(5), 2631-2643.

6. Thompson, R. G., & Wilson, C. M. (2021). Long-term Thermal Stability of FR4 Laminates: A Comprehensive Review. Materials Science and Engineering: R: Reports, 146, 100642.

_1732777843529.webp)