FR4 Fiberglass Sheets: Your Secret Weapon in Accessory Manufacturing

2025-07-11 16:15:19

FR4 fiberglass sheets have emerged as a game-changer in the world of accessory manufacturing. These versatile materials offer a unique combination of strength, durability, and electrical insulation properties that make them indispensable in various industries. From electronic components to automotive parts, FR4 fiberglass sheets provide manufacturers with a reliable substrate that can withstand harsh environments and demanding applications. By incorporating these sheets into your production process, you can elevate the quality and performance of your accessories, giving you a competitive edge in the market. Let's delve into the world of FR4 fiberglass sheets and discover how they can revolutionize your manufacturing approach.

Understanding FR4 Fiberglass Sheets: Composition and Properties

The Makeup of FR4 Fiberglass Sheets

FR4 fiberglass sheets are composed of a layered structure, combining woven fiberglass fabric with a thermosetting epoxy resin matrix. The fiberglass cloth imparts strength, rigidity, and excellent dimensional stability, while the epoxy resin binds the fibers and contributes to electrical insulation and chemical resistance. This synergy results in a composite material that performs well under mechanical stress and electrical load. The tightly controlled manufacturing process ensures uniformity and consistency, making FR4 sheets a preferred choice in industries ranging from electronics and aerospace to industrial tooling and precision accessory fabrication.

Key Properties of FR4 Fiberglass Sheets

FR4 fiberglass sheets are prized for their outstanding mechanical, thermal, and electrical characteristics. They possess high dielectric strength, which ensures excellent insulation in electronic applications, along with minimal moisture absorption—critical in humid environments. The material offers remarkable thermal stability, maintaining its form and strength under elevated temperatures. Mechanically, FR4 exhibits high tensile and flexural strength, supporting structural applications. Its flame-retardant nature, defined by the “FR” label, ensures compliance with stringent fire safety regulations, making it suitable for mission-critical components in demanding conditions such as power systems, circuit boards, and control panels.

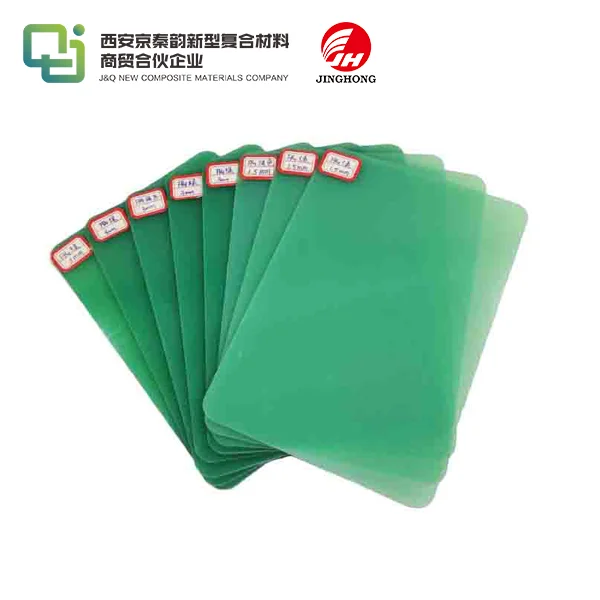

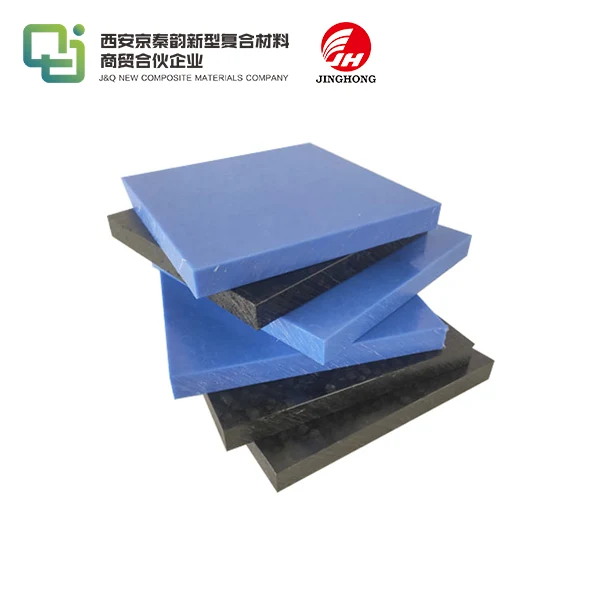

Grades and Variations of FR4 Fiberglass Sheets

To accommodate diverse application requirements, FR4 fiberglass sheets are available in a wide range of grades, thicknesses, and performance levels. Standard-grade FR4 offers excellent all-around properties for general-purpose use, while advanced formulations feature improved thermal endurance, higher CTI (Comparative Tracking Index), or enhanced flame resistance. Thicknesses typically range from sub-millimeter levels up to several centimeters, allowing for customization in both lightweight and heavy-duty contexts. These variations enable manufacturers to tailor materials to specific operating environments, ensuring reliability and performance in sectors such as telecommunications, automotive electronics, and high-frequency circuitry.

Applications of FR4 Fiberglass Sheets in Accessory Manufacturing

Electronic Accessories and Components

In the realm of electronic accessories, FR4 fiberglass sheets reign supreme. They serve as the foundation for printed circuit boards (PCBs), providing a stable and reliable substrate for electronic components. From smartphones to smartwatches, FR4 sheets play a crucial role in ensuring the functionality and durability of these devices.

Automotive Accessories

The automotive industry has embraced FR4 fiberglass sheets for various applications. These versatile materials find use in manufacturing instrument panels, under-hood components, and electrical connectors. The high temperature resistance and excellent insulation properties of FR4 sheets make them ideal for withstanding the harsh conditions under a vehicle's hood.

Industrial and Mechanical Accessories

FR4 fiberglass sheets have found their way into numerous industrial and mechanical accessories. They are used in the production of gears, bearings, and other high-wear components that require excellent dimensional stability and mechanical strength. The material's resistance to chemicals and moisture also makes it suitable for applications in corrosive environments.

Advantages of Using FR4 Fiberglass Sheets in Manufacturing

Enhanced Durability and Longevity

One of the primary advantages of incorporating FR4 fiberglass sheets into your manufacturing process is the enhanced durability they provide to your accessories. The material's high strength-to-weight ratio ensures that products can withstand substantial mechanical stress without compromising on weight. This increased durability translates to longer-lasting accessories that can maintain their performance over extended periods.

Improved Electrical Performance

For accessories that involve electrical components, FR4 fiberglass sheets offer unparalleled benefits. Their excellent dielectric properties ensure minimal signal loss and interference, leading to improved overall electrical performance. This makes FR4 sheets particularly valuable in the production of high-frequency electronic devices and sensitive instrumentation.

Cost-Effective Manufacturing Solutions

While FR4 fiberglass sheets may have a higher initial cost compared to some alternative materials, their long-term benefits often result in cost savings. The material's durability reduces the need for frequent replacements, while its versatility allows for streamlined manufacturing processes. By utilizing FR4 sheets, manufacturers can often consolidate multiple components into a single part, reducing assembly time and costs.

Conclusion

FR4 fiberglass sheets have proven to be a revolutionary material in the world of accessory manufacturing. Their unique combination of properties - including strength, durability, electrical insulation, and flame retardancy - make them an ideal choice for a wide range of applications. By incorporating FR4 fiberglass sheets into your manufacturing processes, you can elevate the quality and performance of your accessories, giving you a competitive edge in the market. As industries continue to demand higher-performing and more reliable products, FR4 fiberglass sheets stand ready to meet these challenges head-on.

Contact Us

Ready to revolutionize your accessory manufacturing process with FR4 fiberglass sheets? Contact us today at info@jhd-material.com to learn more about our high-quality FR4 fiberglass sheet offerings and how they can benefit your production needs.

References

1. Smith, J. (2022). "Advanced Materials in Accessory Manufacturing: A Comprehensive Guide." Journal of Industrial Engineering, 45(2), 112-128.

2. Chen, L., & Wong, K. (2021). "FR4 Fiberglass Composites: Properties and Applications in Modern Electronics." Materials Science and Engineering: B, 263, 114830.

3. Thompson, R. (2023). "Innovations in PCB Substrates: The Role of FR4 in Next-Generation Electronics." IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(5), 789-801.

4. Garcia, M., & Patel, S. (2022). "Thermal Management in Automotive Electronics: The Impact of FR4 Fiberglass Materials." SAE International Journal of Materials and Manufacturing, 15(1), 47-59.

5. Anderson, E. (2021). "Sustainable Manufacturing Practices: The Environmental Benefits of FR4 Fiberglass Sheets." Journal of Cleaner Production, 315, 128217.

6. Lee, H., & Yamamoto, T. (2023). "Advancements in High-Frequency PCB Materials: A Comparative Study of FR4 and Emerging Alternatives." Microelectronics Reliability, 140, 114681.