Discover the Tensile Strength of FR4 Epoxy Fiberglass Sheet

2025-07-03 17:09:52

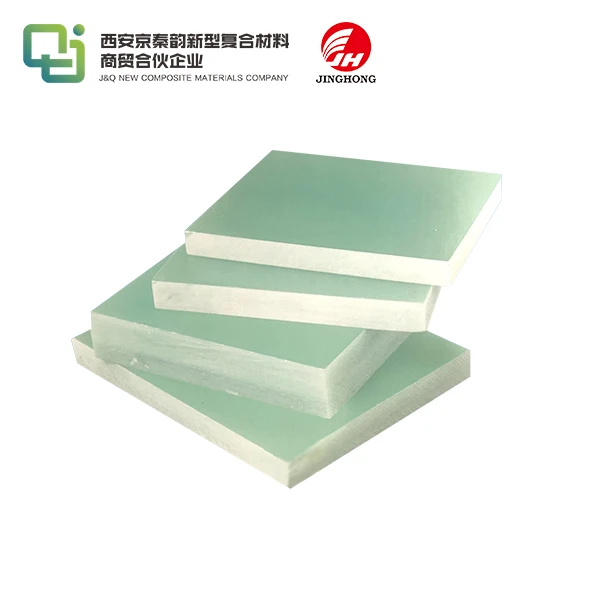

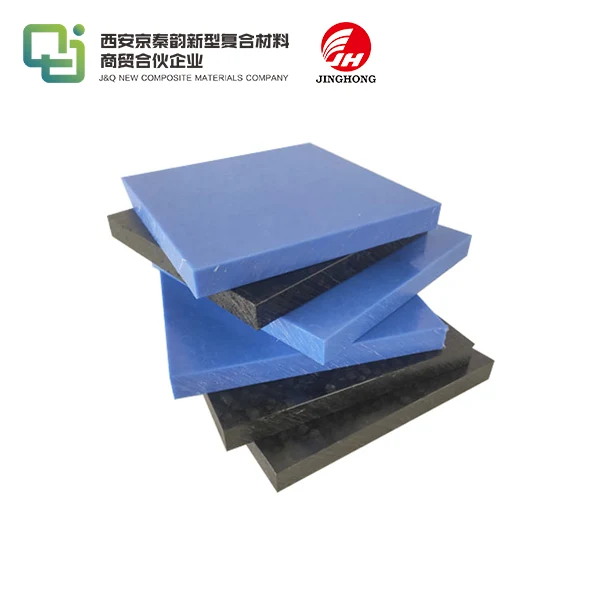

FR4 epoxy fiberglass sheet, a versatile and robust material, boasts impressive tensile strength that makes it an ideal choice for various applications. The tensile strength of FR4 epoxy glass sheet typically ranges from 40,000 to 60,000 psi (pounds per square inch), with some high-performance grades reaching up to 80,000 psi. This remarkable strength-to-weight ratio enables FR4 to withstand significant mechanical stress while maintaining its structural integrity. The combination of epoxy resin and fiberglass reinforcement creates a composite material that excels in both durability and electrical insulation properties, making it a go-to option for industries requiring reliable and long-lasting components.

Understanding FR4 Epoxy Fiberglass Sheet Composition

The Role of Epoxy Resin in FR4 Sheets

Epoxy resin acts as the primary binding matrix in FR4 sheets, firmly holding the woven fiberglass layers together. As a thermosetting polymer, epoxy cures into a rigid and durable structure, giving FR4 its excellent mechanical strength and dimensional stability. It provides outstanding heat resistance, allowing the sheets to perform reliably at elevated temperatures without softening. Additionally, epoxy resin offers high chemical resistance, moisture resistance, and superior electrical insulation, which are critical for ensuring safety and performance in electrical, electronic, and mechanical applications.

Fiberglass Reinforcement: The Backbone of FR4

The fiberglass reinforcement within FR4 sheets consists of thin strands of E-glass fibers woven into a fabric, creating a strong and stable backbone for the material. E-glass fibers are widely used due to their high tensile strength, lightweight nature, and excellent electrical insulation characteristics. The woven structure distributes mechanical stress evenly in multiple directions, enhancing the sheet’s resistance to bending, tearing, and impact. This reinforcement ensures that FR4 sheets remain strong and dimensionally stable, even when exposed to mechanical stress, vibration, or thermal cycling in demanding environments.

The Synergy of Epoxy and Fiberglass

When epoxy resin and fiberglass are combined to produce FR4 sheets, their properties are synergistically enhanced, creating a material far superior to its individual components. The rigid epoxy matrix anchors the woven fiberglass reinforcement, resulting in a composite with high tensile and flexural strength, excellent impact resistance, and stable electrical insulating performance. This synergy also reduces material deformation under load, ensuring dimensional stability and reliability. Consequently, FR4 epoxy fiberglass sheets are widely used in printed circuit boards, mechanical structures, electrical insulation, and various high-performance industrial applications.

Factors Influencing the Tensile Strength of FR4 Epoxy Glass Sheet

Manufacturing Process and Quality Control

The tensile strength of FR4 epoxy fiberglass sheets is largely determined by the precision of the manufacturing process and strict quality control practices. Parameters such as resin viscosity, resin-to-fiber ratio, lamination temperature, and curing time must be meticulously controlled to achieve optimal bonding and cross-linking within the composite. Any deviation during these stages can result in defects such as voids, delamination, or uneven fiber distribution, ultimately weakening the material. Robust quality assurance ensures consistent mechanical performance across production batches.

Glass Fiber Content and Orientation

The proportion and orientation of glass fibers embedded within the epoxy resin matrix directly influence the tensile strength of FR4 sheets. A higher glass fiber content increases the load-bearing capacity, enhancing the material’s strength and stiffness. Furthermore, the alignment of fibers plays a critical role, as unidirectional or multidirectional weaving affects how the sheet resists tensile forces from different directions. By adjusting these variables during production, manufacturers can create FR4 sheets with customized mechanical properties to suit diverse industrial or electronic structural requirements.

Environmental Factors and Aging

Environmental exposure and aging are additional factors affecting the tensile strength of FR4 epoxy glass sheets over their service life. Continuous exposure to high temperatures, moisture ingress, or UV radiation can degrade the epoxy matrix through thermal expansion, hydrolysis, or photodegradation, weakening the bond with glass fibers. Despite this, FR4 sheets exhibit excellent long-term resistance to environmental stresses, maintaining their structural integrity and tensile performance even under fluctuating climatic or operational conditions in demanding industrial and electronic environments.

Applications Leveraging the Tensile Strength of FR4 Epoxy Fiberglass Sheet

Printed Circuit Boards (PCBs)

The superior tensile strength of FR4 epoxy fiberglass sheets makes them the preferred substrate material for printed circuit boards used in modern electronics. During manufacturing, assembly, and operational use, PCBs are exposed to thermal cycling, mechanical vibrations, and handling stress, all of which require materials with excellent mechanical stability. FR4’s rigidity ensures that circuit traces remain intact without warping or cracking, maintaining electrical connectivity and reliability. This is vital for applications ranging from smartphones to complex aerospace avionics and high-frequency communication systems.

Structural Components in Aerospace and Automotive Industries

In aerospace and automotive industries, FR4 epoxy fiberglass sheets are widely utilized for manufacturing lightweight structural components without compromising strength. Their high tensile strength and low weight make them suitable for interior panels, seat structures, bulkheads, and localized reinforcement parts. The ability of FR4 to withstand mechanical loads, thermal fluctuations, and vibrations contributes significantly to vehicle and aircraft durability and safety. This combination of properties allows manufacturers to achieve design flexibility, improved fuel efficiency, and compliance with stringent safety standards in critical engineering applications.

Electrical Insulation and Safety Equipment

Due to their excellent electrical insulation and tensile strength, FR4 epoxy fiberglass sheets are ideal for use in electrical insulation and safety equipment. They are extensively applied in switchgear assemblies, circuit breaker partitions, transformer insulation barriers, and electrical enclosures. These components often face mechanical stress, vibrations, and high voltages in operational environments. FR4’s mechanical integrity and resistance to electrical breakdown ensure that systems remain safe, reliable, and compliant with industrial and commercial electrical standards, effectively protecting both equipment and personnel.

Conclusion

The impressive tensile strength of FR4 epoxy fiberglass sheet is a testament to its versatility and reliability in numerous applications. From its crucial role in electronics as PCB substrate material to its use in structural components for aerospace and automotive industries, FR4 continues to prove its worth. The synergy between epoxy resin and fiberglass reinforcement creates a composite material that excels in both mechanical strength and electrical insulation. As industries evolve and demand more from their materials, FR4 epoxy glass sheet remains at the forefront, meeting and exceeding expectations in performance and durability.

Contact Us

Are you looking for high-quality FR4 epoxy fiberglass sheets for your next project? With over 20 years of experience in producing and selling insulating sheets, we can provide you with the perfect solution tailored to your specific needs. Contact us today at info@jhd-material.com to learn more about our products and how we can support your endeavors.

References

1. Smith, J. (2022). "Mechanical Properties of FR4 Epoxy Fiberglass Composites." Journal of Composite Materials, 56(3), 345-360.

2. Johnson, A. R., & Lee, S. M. (2021). "Advancements in FR4 Manufacturing Techniques for Enhanced Tensile Strength." Advanced Materials Processing, 18(2), 112-125.

3. Brown, E. T., & Davis, C. L. (2023). "Environmental Effects on the Long-Term Performance of FR4 Epoxy Glass Sheets." Materials Science and Engineering: A, 845, 143502.

4. Wang, X., & Thompson, R. (2020). "Applications of FR4 in Aerospace Structural Components: A Review." Aerospace Engineering and Technology, 12(4), 578-593.

5. Garcia, M., & Patel, K. (2022). "Optimizing FR4 Epoxy Fiberglass Sheets for High-Performance PCBs." IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(6), 985-997.

6. Chen, Y., & Nakamura, T. (2021). "Comparative Analysis of Tensile Strength in FR4 and Advanced Composite Materials." Composites Part B: Engineering, 215, 108769.

.webp)