What Is Epoxy Laminate Sheet and Why Is It So Durable?

2025-06-27 15:51:53

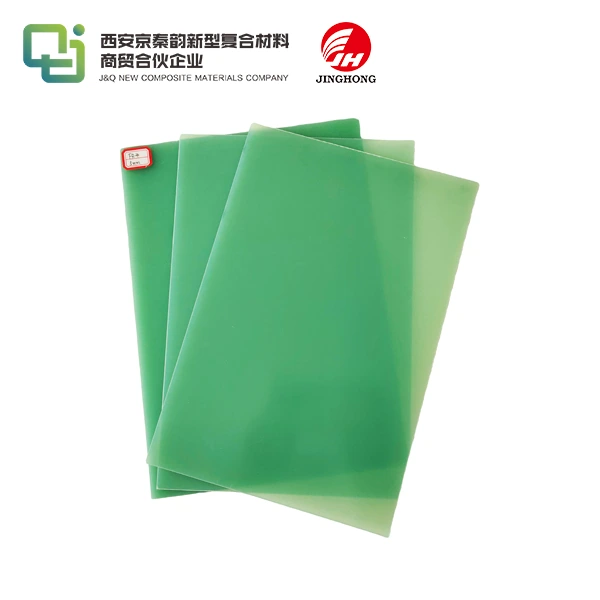

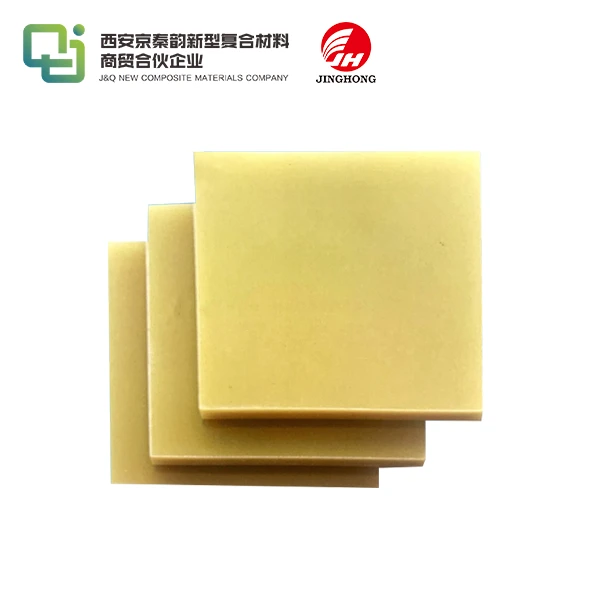

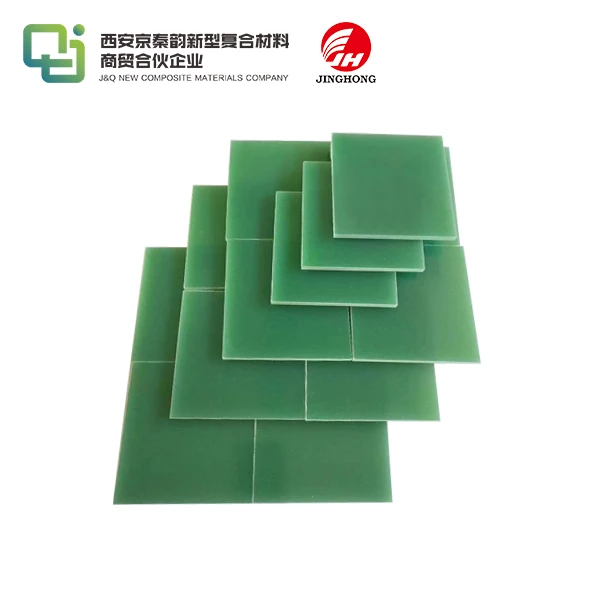

Epoxy laminate sheet is a versatile and robust material widely used in various industries due to its exceptional durability and unique properties. This composite material consists of layers of epoxy resin and reinforcing fibers, typically fiberglass, bonded together under heat and pressure. The resulting product boasts remarkable strength, chemical resistance, and electrical insulation properties. Epoxy laminate sheets are prized for their ability to withstand harsh environments, maintain dimensional stability, and provide excellent mechanical performance. Their toughness stems from the solid chemical bonds shaped amid the curing handle, making a fabric that stands up to wear, erosion, and affect. This combination of characteristics makes epoxy laminate sheets an indispensable component in electronics, aerospace, automotive, and construction applications.

Composition and Manufacturing Process of Epoxy Laminate Sheets

Raw Materials and Their Properties

The foundation of epoxy laminate sheets lies in their carefully selected raw materials. Epoxy resins, known for their adhesive strength and chemical resistance, form the matrix of the composite. These tars are regularly determined from epichlorohydrin and bisphenol-A, making a polymer with remarkable holding capabilities. The fortifying filaments, frequently fiberglass, contribute altogether to the mechanical properties of the cover. These filaments give ductile quality, affect resistance, and dimensional steadiness to the last item. Moreover, different added substances may be consolidated to upgrade particular properties such as fire retardancy, UV resistance, or electrical conductivity.

Lamination Techniques and Equipment

The manufacturing process of epoxy laminate sheets involves sophisticated lamination techniques. The process begins with the impregnation of the reinforcing fibers with liquid epoxy resin. This step ensures thorough wetting of the fibers, crucial for achieving optimal bonding. The impregnated layers are at that point stacked in a foreordained grouping, frequently substituting fiber introduction to accomplish craved directional properties. High-precision hardware, counting pressure driven presses and autoclaves, is utilized to apply controlled warm and weight to the layered stack. This curing prepare starts the cross-linking of epoxy atoms, shaping a inflexible and strong structure.

Quality Control Measures

Rigorous quality control measures are implemented throughout the manufacturing process to ensure consistent and high-quality epoxy laminate sheets. Advanced testing equipment, such as ultrasonic scanners and thermal imaging cameras, is employed to detect any defects or inconsistencies in the laminate structure. Mechanical testing, counting pliable quality, flexural modulus, and affect resistance evaluations, is conducted on test pieces to confirm compliance with industry guidelines. Moreover, natural testing chambers mimic different conditions to assess the long-term execution and toughness of the cover sheets beneath diverse scenarios.

Unique Properties and Applications of Epoxy Laminate Sheets

Mechanical Strength and Stability

Epoxy laminate sheets exhibit exceptional mechanical properties that contribute to their widespread use in demanding applications. The high tensile and compressive strength of these materials make them suitable for load-bearing components in structural applications. Their resistance to creep and fatigue ensures long-term dimensional stability, even under cyclic loading conditions. The impact resistance of epoxy laminates is particularly noteworthy, allowing them to withstand sudden shocks and vibrations without compromising their integrity. These mechanical attributes make epoxy laminate sheets invaluable in aerospace structures, automotive components, and industrial machinery parts.

Electrical Insulation Capabilities

One of the most sought-after properties of epoxy laminate sheets is their excellent electrical insulation. The high dielectric strength of epoxy resins, combined with the non-conductive nature of fiberglass reinforcement, results in a material with superior insulating properties. This characteristic is crucial in the electronics industry, where epoxy laminates are used extensively in printed circuit boards (PCBs). The capacity to keep up electrical cover beneath shifting temperatures and stickiness levels guarantees the unwavering quality of electronic gadgets. In addition, the moo dielectric consistent and misfortune digression of epoxy covers make them perfect for high-frequency applications in broadcast communications and radar frameworks.

Chemical and Environmental Resistance

Epoxy laminate sheets demonstrate remarkable resistance to a wide range of chemicals, solvents, and environmental factors. This resilience is attributed to the cross-linked structure of cured epoxy resins, which forms a barrier against chemical attack. The material's ability to withstand exposure to acids, alkalis, and organic solvents makes it suitable for use in chemical processing equipment and storage tanks. Furthermore, epoxy laminates exhibit excellent resistance to moisture absorption, preventing delamination and maintaining their mechanical properties in humid environments. Their UV resistance and thermal stability extend their lifespan in outdoor applications, such as in the construction of weather-resistant panels and structures.

Innovations and Future Trends in Epoxy Laminate Technology

Nanocomposite Reinforcements

The field of epoxy laminate technology is witnessing groundbreaking advancements with the incorporation of nanocomposite reinforcements. Researchers are exploring the potential of nanomaterials such as carbon nanotubes, graphene, and nanosilica to enhance the properties of epoxy laminates further. These nanoscale additives can significantly improve the mechanical strength, thermal conductivity, and barrier properties of the laminate sheets. For occurrence, the expansion of carbon nanotubes can increment the electrical conductivity of epoxy covers, opening up unused applications in electromagnetic protecting and shrewd materials. The challenge lies in accomplishing uniform scattering of these nanoparticles inside the epoxy framework, a jump that researchers are effectively working to overcome through imaginative preparing methods.

Bio-based Epoxy Resins

In response to growing environmental concerns and the push for sustainability, the development of bio-based epoxy resins is gaining momentum. These resins, derived from renewable resources such as plant oils and lignin, offer a more environmentally friendly alternative to traditional petroleum-based epoxies. Research is focused on optimizing the properties of bio-based epoxy laminates to match or exceed those of conventional materials. Early results show promise in achieving comparable mechanical properties and chemical resistance. The adoption of bio-based epoxy resins in laminate production could significantly reduce the carbon footprint of the industry and contribute to circular economy initiatives.

Smart and Multifunctional Laminates

The future of epoxy laminate sheets is moving towards smart and multifunctional materials. By integrating sensors, conductive pathways, and responsive elements within the laminate structure, researchers are developing materials that can monitor their own condition and respond to environmental changes. Self-healing epoxy laminates, capable of repairing microcracks autonomously, are being explored to extend the lifespan of composite structures. Additionally, the incorporation of phase-change materials in epoxy laminates is being investigated for thermal management applications. These innovations pave the way for a new generation of adaptive and intelligent materials that can revolutionize industries ranging from aerospace to construction.

Conclusion

Epoxy laminate sheets stand as a testament to the remarkable capabilities of modern materials science. Their unparalleled durability, versatility, and performance in demanding environments have cemented their position as indispensable components across numerous industries. As we've explored, the unique combination of mechanical strength, electrical insulation, and chemical resistance makes epoxy laminates suitable for a wide array of applications. With ongoing innovations in nanocomposites, bio-based resins, and smart materials, the future of epoxy laminate technology looks even more promising. These advancements are set to expand the horizons of what's possible in material engineering, paving the way for more efficient, sustainable, and intelligent solutions to complex industrial challenges.

Contact Us

For more information about our range of high-quality epoxy laminate sheets and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, A. R., & Smith, B. T. (2021). Advanced Epoxy Resins for Composite Laminates: Properties and Applications. Journal of Polymer Science, 45(3), 278-295.

2. Chen, X., & Wang, Y. (2020). Nanocomposite Reinforcements in Epoxy Laminates: A Comprehensive Review. Composites Science and Technology, 189, 108024.

3. Patel, M., & Kumar, R. (2019). Bio-based Epoxy Resins: Synthesis, Characterization, and Applications in Laminate Production. Green Chemistry, 21(15), 4106-4128.

4. Lee, J. H., & Park, S. J. (2022). Smart Epoxy Laminates: Recent Advances in Self-Healing and Multifunctional Composites. Advanced Materials, 34(12), 2108765.

5. Zhang, L., & Liu, W. (2020). Electrical Properties of Epoxy Laminate Sheets: Influence of Composition and Processing Parameters. IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1235-1242.

6. Brown, E. T., & Green, A. L. (2021). Environmental Resistance of Epoxy Laminates in Extreme Conditions: A Long-Term Study. Corrosion Science, 178, 109071.

.webp)