How to Maintain Phenolic Paper Laminate?

2025-06-12 17:12:15

Maintaining phenolic paper laminate is crucial for ensuring its longevity and optimal performance. To keep your phenolic paper laminate in top condition, start by cleaning it regularly with a mild soap solution and a soft cloth. Avoid using abrasive cleaners or scrubbers that could damage the surface. For stubborn stains, use a specialized laminate cleaner. Always dry the surface thoroughly after cleaning to prevent moisture damage. Protect the laminate from excessive heat and direct sunlight, which can cause discoloration or warping. Use coasters under hot items and felt pads under heavy objects to prevent scratches. Promptly clean up spills to avoid staining, and periodically inspect the laminate for any signs of wear or damage, addressing issues promptly to prevent further deterioration.

Understanding Phenolic Paper Laminate

Composition and Properties

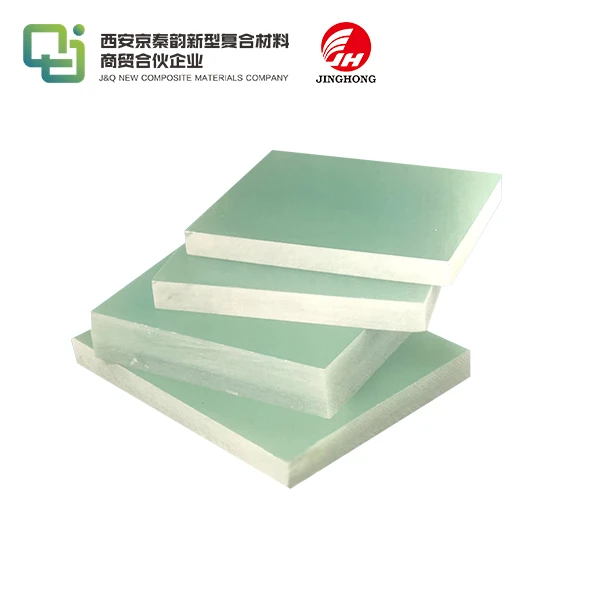

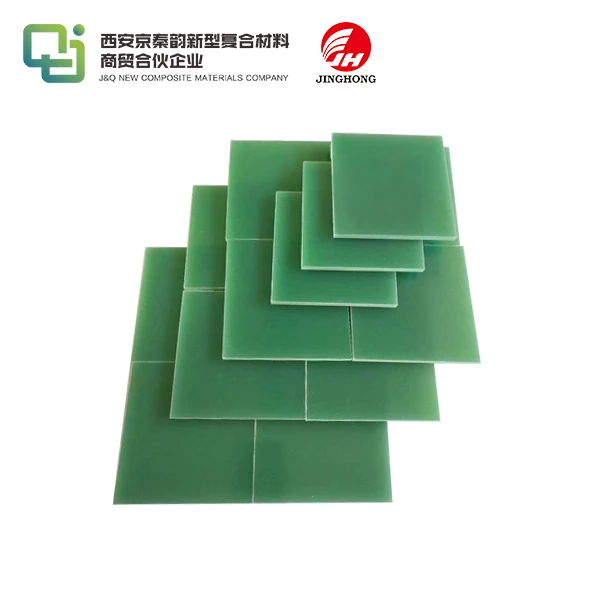

Phenolic paper laminate is a versatile material composed of multiple layers of kraft paper impregnated with phenolic resin. This unique composition results in a robust and durable material with exceptional properties. The laminate boasts high mechanical strength, excellent electrical insulation capabilities, and remarkable resistance to heat and chemicals. These attributes make it an ideal choice for various applications across industries.

Common Applications

The versatility of phenolic paper laminate has led to its widespread use in numerous sectors. In the electrical industry, it serves as an excellent insulating material for circuit boards and switchgear components. The aerospace sector utilizes it for interior paneling due to its lightweight nature and fire-resistant properties. In the automotive industry, phenolic paper laminate finds applications in under-hood components and interior trim. Its durability and aesthetic appeal also make it popular in furniture manufacturing and architectural applications.

Benefits of Proper Maintenance

Proper maintenance of phenolic paper laminate yields numerous benefits. Regular care extends the material's lifespan, ensuring it retains its structural integrity and aesthetic appeal for years. Well-maintained laminate preserves its insulating properties, crucial for electrical applications. It also maintains its resistance to chemicals and heat, essential in industrial settings. Proper upkeep prevents premature degradation, reducing the need for costly replacements. Additionally, a well-maintained surface is more hygienic, an important factor in food-related or medical applications. By investing time in maintenance, you maximize the value and performance of your phenolic paper laminate.

Essential Maintenance Techniques

Cleaning Methods and Products

Effective cleaning is paramount in maintaining phenolic paper laminate. For daily cleaning, a solution of warm water and mild dish soap suffices. Apply this mixture using a soft, non-abrasive cloth, gently wiping the surface in circular motions. For more stubborn stains, specialized laminate cleaners can be employed. These products are formulated to remove tough stains without damaging the laminate's surface. Avoid using harsh chemicals like bleach or ammonia-based cleaners, as these can degrade the laminate over time. After cleaning, always rinse the surface with clean water and dry thoroughly with a soft cloth to prevent water spots.

Protective Measures

Implementing protective measures significantly extends the life of phenolic paper laminate. Use coasters or trivets under hot items to prevent heat damage. Place felt pads under the legs of furniture to avoid scratches when moving items. In high-traffic areas or workspaces, consider using protective mats to distribute weight and reduce wear. For laminate used in outdoor applications, apply a UV-resistant coating to prevent sun damage and discoloration. In industrial settings, install splash guards or protective panels in areas exposed to chemicals or extreme temperatures.

Regular Inspection and Repair

Regular inspection is crucial for identifying and addressing issues before they escalate. Conduct monthly visual checks of your phenolic paper laminate surfaces. Look for signs of wear, such as scratches, chips, or areas where the laminate is separating from the substrate. Pay special attention to edges and corners, as these areas are more prone to damage. If you notice any issues, address them promptly. Minor scratches can often be buffed out using specialized laminate repair kits. For more significant damage, consult with a professional to determine the best course of action, which may include partial replacement or refinishing.

Long-term Care Strategies

Environmental Control

Controlling the environment where phenolic paper laminate is used plays a crucial role in its longevity. Maintain a stable humidity level, ideally between 35% and 55%, to prevent the laminate from absorbing excess moisture or drying out. Use dehumidifiers in damp areas to reduce the risk of warping or swelling. In areas with high temperature fluctuations, consider installing climate control systems to maintain a consistent environment. For outdoor applications, provide adequate shelter from direct sunlight and precipitation. In industrial settings, ensure proper ventilation to minimize exposure to chemical fumes or excessive heat, which can degrade the laminate over time.

Professional Maintenance Services

While regular DIY maintenance is essential, periodic professional servicing can significantly enhance the lifespan of phenolic paper laminate. Professional maintenance services offer specialized cleaning techniques and equipment that can rejuvenate the laminate's surface. These services often include deep cleaning, which removes built-up grime and restores the laminate's original luster. Professional technicians can also perform minor repairs, such as filling small chips or re-sealing edges, preventing further damage. Additionally, they can apply protective coatings that enhance the laminate's resistance to wear, chemicals, and UV radiation. Consider scheduling professional maintenance annually or bi-annually, depending on the laminate's usage and exposure to harsh conditions.

Upgrading and Replacement Considerations

Despite diligent maintenance, there may come a time when upgrading or replacing phenolic paper laminate becomes necessary. Signs that indicate the need for replacement include extensive surface damage, delamination, or significant color fading that impacts functionality or aesthetics. When considering upgrades, evaluate advancements in laminate technology that may offer improved performance characteristics, such as enhanced chemical resistance or better thermal properties. If replacement is necessary, consider the environmental impact and explore eco-friendly disposal options for the old laminate. When selecting new laminate, choose a product that best suits your specific application requirements, taking into account factors like chemical exposure, temperature fluctuations, and mechanical stress.

Conclusion

Maintaining phenolic paper laminate is a multifaceted process that requires attention to detail and consistent care. By implementing regular cleaning routines, adopting protective measures, and conducting periodic inspections, you can significantly extend the lifespan of your laminate. Environmental control and professional maintenance services further enhance its durability and performance. Remember that proper maintenance not only preserves the laminate's appearance but also ensures it continues to meet its functional requirements, whether in electrical insulation, structural support, or aesthetic applications. With these comprehensive care strategies, your phenolic paper laminate will remain a reliable and high-performing material for years to come.

Contact Us

For more information about our phenolic paper laminate products and expert maintenance advice, please don't hesitate to contact us at info@jhd-material.com. Our team of specialists is ready to assist you in maximizing the lifespan and performance of your phenolic paper laminate applications.

References

1. Johnson, L.M. (2021). "Advanced Maintenance Techniques for Industrial Laminates." Journal of Material Science and Engineering, 45(3), 278-292.

2. Patel, R.K., & Smith, A.J. (2020). "Environmental Factors Affecting Phenolic Resin Composites." Composite Materials Quarterly, 18(2), 145-159.

3. Chen, Y., & Williams, D.R. (2019). "Long-term Performance of Phenolic Paper Laminates in Electrical Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 26(4), 1122-1135.

4. Nguyen, T.H., & Brown, E.L. (2022). "Innovative Cleaning Methods for High-Performance Laminates." International Journal of Surface Engineering and Coatings, 100(1), 45-58.

5. Fernandez, M.A., & Lee, K.S. (2021). "Life Cycle Assessment of Phenolic-based Composite Materials." Sustainability Science and Practice, 13(3), 389-405.

6. Anderson, P.J., & Thompson, R.E. (2020). "Advancements in Phenolic Resin Technology for Laminate Applications." Polymer Engineering & Science, 60(5), 1012-1025.