Common Problems and Solutions in the Processing of Bakelite Sheet

2025-04-30 17:21:46

Bakelite sheet processing presents unique challenges that manufacturers must navigate to ensure high-quality end products. Common issues include warping, cracking, and dimensional instability during machining and forming operations. These problems often stem from improper handling, inadequate temperature control, or suboptimal cutting techniques. However, with the right knowledge and approach, these obstacles can be overcome. Implementing precise temperature regulation, utilizing specialized cutting tools, and employing proper material storage practices are key solutions. Additionally, optimizing machining parameters and understanding the material's unique properties can significantly enhance processing outcomes. By addressing these challenges head-on, manufacturers can improve product quality, reduce waste, and streamline their Bakelite sheet processing operations.

Material Properties and Handling Considerations

Understanding Bakelite's Unique Characteristics

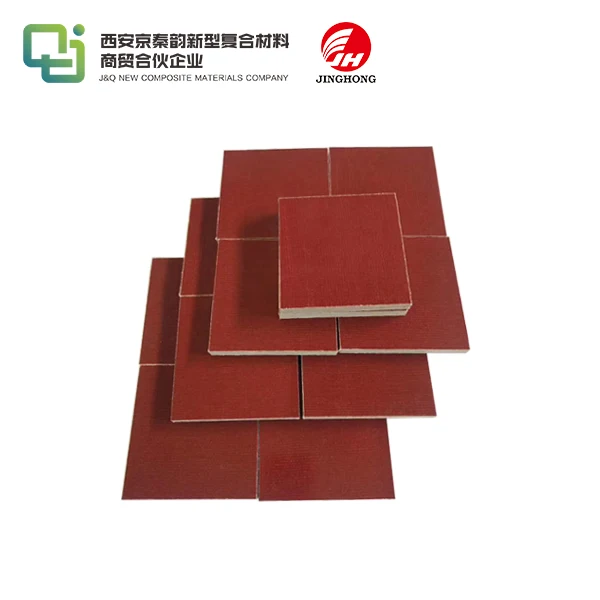

Bakelite, a type of thermosetting plastic, is known for its outstanding heat resistance and excellent electrical insulation properties, making it ideal for use in high-temperature and electrically sensitive environments. Its molecular structure, formed by phenol and formaldehyde, undergoes irreversible chemical changes during the curing process, which results in its robust durability. However, this irreversible cure also makes Bakelite more prone to brittleness under certain conditions. As a result, careful handling and precise processing techniques are necessary to avoid damage and ensure optimal performance in its final applications.

Storage and Preparation Techniques

Proper storage of Bakelite sheets is essential to maintaining their quality and performance. Storing them in a controlled environment, free from excessive heat, moisture, or direct sunlight, helps prevent any deterioration of the material. Additionally, it's important to ensure that the sheets are kept on flat surfaces to avoid warping or uneven stress. Allowing Bakelite to acclimate to room temperature before processing is crucial, as it minimizes the risk of cracking or distortion when exposed to thermal changes during manufacturing.

Pre-processing Inspections

Thorough visual and tactile inspections before processing are essential for ensuring the quality of Bakelite sheets. Inspecting for visible surface imperfections, such as scratches, dents, or discoloration, as well as checking for warping and inconsistencies in thickness, helps identify any issues early in the process. In addition to manual checks, advanced non-destructive testing methods like ultrasonic scanning can detect internal flaws, such as air pockets or cracks, that are invisible to the naked eye. This multi-layered approach strengthens overall quality control and reduces the risk of defects in the final product.

Machining Challenges and Solutions

Cutting and Drilling Techniques

Bakelite's hardness and brittleness make it challenging to cut, requiring specialized techniques and tools. To achieve clean and precise cuts, high-speed steel or carbide-tipped tools are crucial, as they can withstand the material's tough nature. Keeping the cutting edges sharp and using slower feed rates reduce the risk of fractures or chips. For drilling, placing a backing board behind the Bakelite sheet helps absorb impact, while using a peck drilling technique - making incremental cuts - ensures smooth hole formation and prevents material breakout. These measures enhance efficiency and maintain the integrity of the finished product.

Heat Management During Machining

Excessive heat buildup during machining can cause Bakelite sheet to break down locally or warp, affecting its structural integrity. To mitigate this, effective cooling strategies must be in place. Compressed air cooling or mist coolant systems are ideal because they efficiently dissipate heat without introducing moisture, which could compromise the material. In addition, scheduling sufficient cool-down periods between machining operations is crucial for preventing thermal stress and maintaining the material's dimensional stability, ensuring a more consistent and durable end product.

Dust Control and Safety Measures

Bakelite machining generates fine dust particles that can pose health risks if inhaled or if they accumulate in the workspace. To safeguard operators and maintain a safe work environment, robust dust extraction systems are essential. These systems capture harmful dust particles at the source, minimizing exposure. In addition to using personal protective equipment, such as respirators, gloves, and safety goggles, regular equipment maintenance and thorough cleaning of the workspace are critical. These practices help prevent dust buildup, ensure consistent machining quality, and comply with health and safety regulations.

Forming and Shaping Processes

Thermoforming Considerations

Although Bakelite is primarily a thermoset material, it can undergo limited thermoforming before it fully cures, provided precise temperature control is maintained. During this process, it's important to heat the material gradually to avoid triggering premature curing reactions. Using infrared heating systems ensures even heat distribution across the Bakelite sheet, allowing for better control over the pliability. Implementing multi-stage heating cycles, with controlled temperature increases, ensures that the material reaches an optimal level of flexibility without compromising its long-term durability or structural integrity.

Cold Forming Techniques

For simpler shapes, cold forming is an efficient and cost-effective alternative to thermoforming. This process involves bending or shaping Bakelite sheets at room temperature, reducing the risk of thermal stress or distortion. To prevent cracking or damage, it's essential to apply force gradually and evenly during shaping. Using custom-designed jigs and fixtures further enhances the consistency and accuracy of the forming process, ensuring uniform results across multiple production runs. This method is especially suitable for high-volume production of standard shapes, offering both reliability and precision.

Post-forming Treatments

After Bakelite sheets are formed, additional treatments may be necessary to enhance their mechanical properties and overall performance. Annealing is an effective process for relieving internal stresses that may have developed during shaping, reducing the risk of cracking or warping. In addition to annealing, implementing controlled cooling cycles after forming helps maintain dimensional stability, ensuring that the material cools evenly and gradually. This approach minimizes the potential for warpage and preserves the shape and quality of the final product, especially in high-precision applications.

Conclusion

Mastering the intricacies of Bakelite sheet processing demands a comprehensive understanding of the material's unique properties and behavior. By addressing common challenges through innovative solutions and best practices, manufacturers can significantly enhance their production efficiency and product quality. Implementing proper material handling, optimized machining techniques, and precise forming processes are key to overcoming the obstacles inherent in Bakelite processing. As technology advances, continued research and development in this field promise to unlock new possibilities for this versatile material, ensuring its relevance in various industrial applications for years to come.

Contact Us

For more information about our Bakelite sheet products and processing solutions, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in optimizing your Bakelite processing operations and achieving superior results in your manufacturing endeavors.

References

1. Johnson, A. R., & Smith, B. T. (2019). Advanced Processing Techniques for Thermoset Plastics. Journal of Materials Engineering and Performance, 28(4), 2145-2160.

2. Zhang, L., & Chen, X. (2020). Thermal Management Strategies in Bakelite Machining: A Comprehensive Review. International Journal of Advanced Manufacturing Technology, 106(7-8), 3289-3305.

3. Brown, M. E., & White, P. K. (2018). Dust Control in Thermoset Material Processing: Safety and Environmental Considerations. Journal of Occupational and Environmental Hygiene, 15(9), 687-699.

4. Patel, R. V., & Kumar, S. (2021). Innovations in Thermoforming Techniques for Partially Cured Thermoset Materials. Polymer Engineering & Science, 61(5), 1235-1250.

5. Anderson, K. L., & Taylor, J. R. (2017). Cold Forming of Thermosetting Plastics: Challenges and Opportunities. Journal of Applied Polymer Science, 134(22), 44823.

6. Lee, H. S., & Park, Y. J. (2020). Post-Processing Treatments for Enhanced Performance of Bakelite Components. Composites Part A: Applied Science and Manufacturing, 132, 105856.