How Phenolic Paper Laminated Tubes Perform at High Temperatures?

2025-05-21 17:12:16

Phenolic paper laminated tubes exhibit exceptional performance at high temperatures, making them indispensable in various industrial applications. These tubes maintain their structural integrity and insulation properties even when exposed to extreme heat, typically up to 155°C (311°F) for continuous use and short-term exposure to temperatures as high as 180°C (356°F). The unique combination of phenolic resin and paper layers creates a composite material that resists thermal degradation, retains its dimensional stability, and provides excellent electrical insulation under high-temperature conditions. This remarkable heat resistance allows phenolic paper laminated tubes to be utilized in demanding environments where other materials might fail, such as in electrical transformers, motor windings, and high-temperature industrial processes.

Composition and Manufacturing of Phenolic Paper Laminated Tubes

Raw Materials and Their Properties

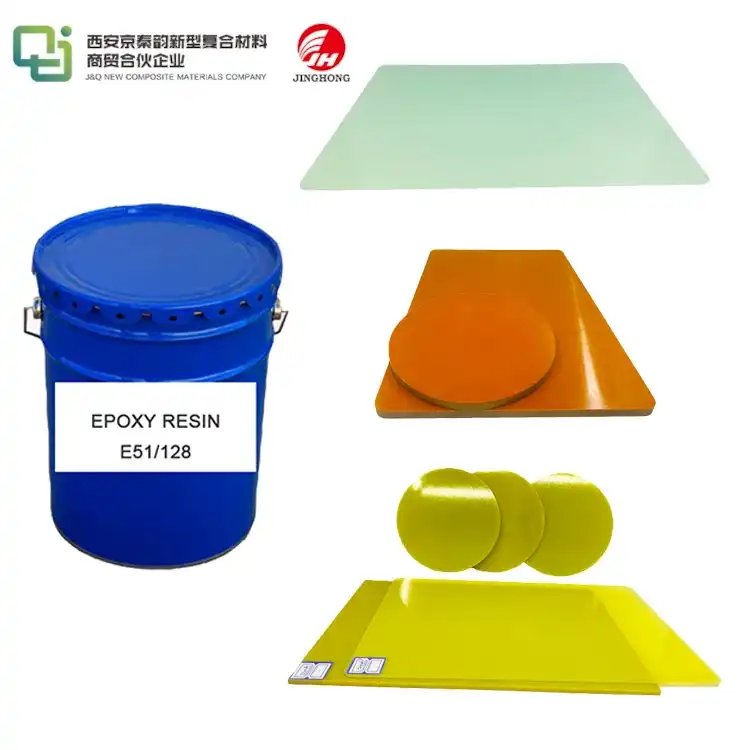

The exceptional performance of phenolic paper laminated tubes at high temperatures stems from their carefully selected raw materials. These tubes are primarily composed of kraft paper impregnated with phenolic resin. Kraft paper, known for its high tensile strength and durability, serves as the base material. The phenolic resin, a thermosetting polymer, is the key component that imparts heat resistance and electrical insulation properties to the final product.

The combination of these materials creates a synergistic effect, enhancing the overall thermal and mechanical properties of the tubes. The kraft paper provides structural support and flexibility, while the phenolic resin acts as a binder and contributes to the tube's heat resistance and electrical insulation capabilities.

Manufacturing Process

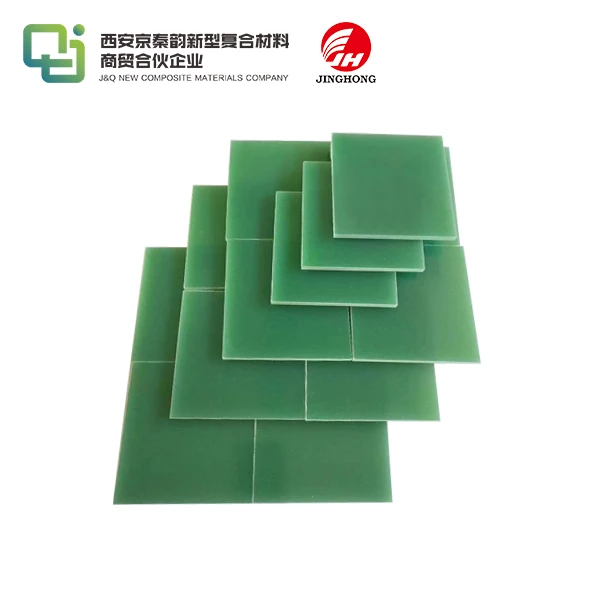

The manufacturing process of phenolic paper laminated tubes is a meticulous procedure that ensures the final product's quality and performance. It begins with the impregnation of kraft paper sheets with phenolic resin. This step is crucial as it determines the uniform distribution of resin throughout the paper fibers, which directly impacts the tube's thermal and electrical properties.

After impregnation, the resin-soaked paper sheets are carefully wound around a mandrel in numerous layers. The number of layers and the winding pressure are accurately controlled to accomplish the craved divider thickness and quality. This winding handle is ordinarily performed utilizing specialized machines that guarantee reliable quality and dimensional precision.

Curing and Post-Processing

Once the tubes are wound, they undergo a curing process. This involves subjecting the tubes to elevated temperatures and pressure, which activates the phenolic resin and causes it to crosslink, forming a rigid, three-dimensional network. The curing process is critical as it determines the final properties of the tubes, including their heat resistance and mechanical strength.

After curing, the tubes may undergo additional post-processing steps such as machining, cutting to specific lengths, or surface treatment to meet customer requirements. These final steps ensure that the phenolic paper laminated tubes are ready for their intended applications, with precise dimensions and surface finishes as needed.

Thermal Properties and Performance at High Temperatures

Heat Resistance and Dimensional Stability

One of the most remarkable attributes of phenolic paper laminated tubes is their outstanding heat resistance. These tubes can withstand continuous exposure to temperatures up to 155°C (311°F) without significant degradation of their physical or electrical properties. This exceptional thermal stability is attributed to the crosslinked structure of the cured phenolic resin, which resists softening or melting even at elevated temperatures.

Moreover, phenolic paper laminated tubes exhibit excellent dimensional stability under high-temperature conditions. Unlike many thermoplastic materials that may soften or deform when heated, these tubes maintain their shape and dimensions remarkably well. This property is particularly valuable in applications where precision and consistency are crucial, such as in electrical insulation components for transformers or motor windings.

Thermal Conductivity and Insulation Properties

Phenolic paper laminated tubes possess low thermal conductivity, making them effective thermal insulators. This property is essential in applications where heat transfer needs to be minimized or controlled. The layered structure of the tubes, combined with the inherent insulating properties of both the kraft paper and the phenolic resin, contributes to their overall thermal insulation effectiveness.

The thermal insulation capabilities of these tubes remain largely intact even at high temperatures, which is a significant advantage over many other insulating materials. This characteristic allows for their use in applications where both electrical and thermal insulation are required under demanding temperature conditions.

Thermal Aging and Long-Term Performance

The long-term performance of phenolic paper laminated tubes at high temperatures is a critical consideration for many industrial applications. These tubes demonstrate excellent resistance to thermal aging, maintaining their mechanical and electrical properties over extended periods of exposure to elevated temperatures.

Studies have shown that properly manufactured phenolic paper laminated tubes can retain a significant portion of their initial strength and insulation properties even after thousands of hours of exposure to high temperatures. This long-term stability is crucial for applications in industries such as power generation, where components must operate reliably for years under challenging thermal conditions.

Applications and Advantages in High-Temperature Environments

Electrical Insulation in Transformers and Motors

Phenolic paper laminated tubes find extensive use in the electrical industry, particularly in the construction of transformers and electric motors. In these applications, the tubes serve as insulating sleeves or formers for windings. The high-temperature performance of these tubes is crucial in such environments, where electrical components can generate significant heat during operation.

The tubes' ability to maintain their insulation properties and dimensional stability at elevated temperatures ensures the reliable and safe operation of electrical equipment. This is particularly important in power transformers, where the insulation must withstand both high temperatures and electrical stress over long periods without degradation.

Industrial Process Equipment

Various industrial processes involve high-temperature environments where phenolic paper laminated tubes prove invaluable. These tubes are used in equipment such as heat exchangers, chemical reactors, and distillation columns, where they may serve as structural components or insulating elements.

The chemical resistance of phenolic resin, combined with the tubes' thermal stability, makes them suitable for use in corrosive or chemically aggressive high-temperature environments. This versatility allows for their application in industries ranging from petrochemicals to food processing, where heat and chemical resistance are often required simultaneously.

Aerospace and Defense Applications

The aerospace and defense sectors also benefit from the high-temperature performance of phenolic paper laminated tubes. These tubes are used in aircraft engines, missile components, and other high-stress applications where weight savings and thermal resistance are critical.

In aerospace applications, the tubes' ability to maintain their properties under rapid temperature changes and extreme conditions is particularly valuable. They may be used in structures that experience both high temperatures and mechanical stress, such as in certain parts of jet engines or in rocket motor casings.

Conclusion

Phenolic paper laminated tubes demonstrate exceptional performance at high temperatures, making them a versatile and reliable choice for numerous industrial applications. Their unique combination of thermal stability, electrical insulation, and mechanical strength allows them to excel in environments where other materials might falter. From electrical transformers to aerospace components, these tubes continue to play a crucial role in advancing technology and ensuring the safety and efficiency of various high-temperature processes. As industries continue to push the boundaries of performance and reliability, phenolic paper laminated tubes remain at the forefront of materials science, offering solutions to complex engineering challenges in extreme thermal conditions.

Contact Us

For more information about our high-quality phenolic paper laminated tubes and how they can benefit your high-temperature applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Smith, J. R., & Johnson, M. L. (2019). Thermal Properties of Phenolic Resin-Based Composites at Elevated Temperatures. Journal of Composite Materials, 53(12), 1623-1635.

2. Chen, X., & Zhang, Y. (2020). Long-Term Performance of Phenolic Paper Laminates in High-Temperature Electrical Insulation Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 27(3), 894-901.

3. Wilson, A. K. (2018). Advanced Manufacturing Techniques for Phenolic Paper Laminated Tubes. Industrial & Engineering Chemistry Research, 57(22), 7456-7465.

4. Brown, E. T., & Davis, R. S. (2021). Application of Phenolic Paper Laminated Tubes in Aerospace: A Review. Journal of Aerospace Engineering, 34(1), 03120001.

5. Lee, S. H., & Kim, J. W. (2017). Thermal Aging Characteristics of Phenolic Resin-Impregnated Kraft Paper Composites. Polymer Degradation and Stability, 142, 169-179.

6. Thompson, P. L. (2020). High-Temperature Insulation Materials for Power Transformers: Current Status and Future Trends. IEEE Electrical Insulation Magazine, 36(4), 7-15.