Epoxy Sheet vs Fiberglass Sheet: Which is Better?

2025-05-27 17:10:26

When it comes to choosing between epoxy sheet and fiberglass sheet, the answer isn't always straightforward. Both materials offer unique properties and excel in different applications. Epoxy sheets are renowned for their exceptional chemical resistance, electrical insulation, and dimensional stability. They're often preferred in electrical and electronic applications. Fiberglass sheets, on the other hand, boast superior strength-to-weight ratio, excellent thermal insulation, and corrosion resistance, making them ideal for construction and marine industries. The choice between the two depends on specific project requirements, environmental conditions, and budget considerations. This comprehensive comparison will delve into the characteristics, advantages, and applications of both materials to help you make an informed decision.

Material Composition and Properties

Epoxy Sheet Composition

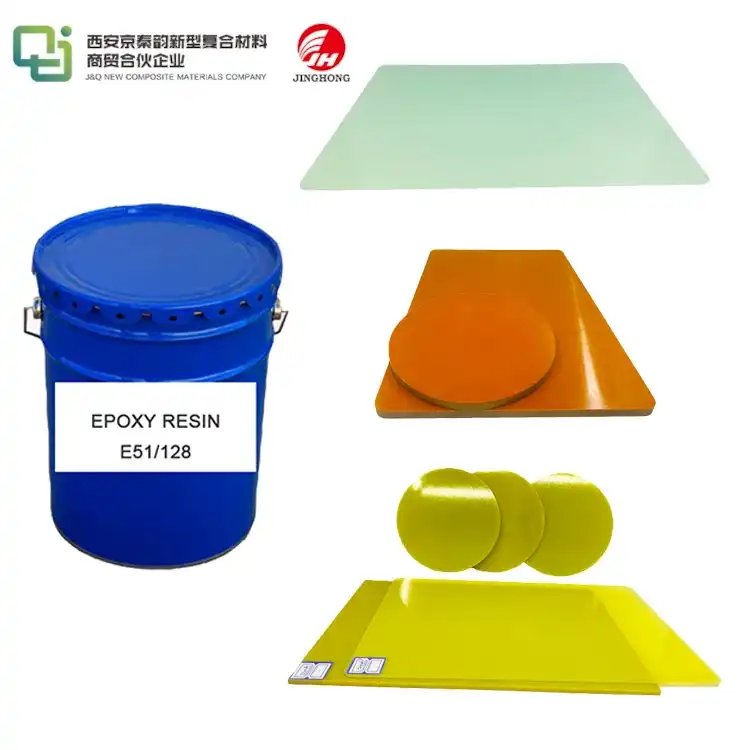

Epoxy sheets are composed primarily of epoxy resin combined with reinforcing fibers such as glass, carbon, or aramid. The epoxy resin, being a thermosetting polymer, provides a rigid and chemically resistant matrix. The reinforcing fibers enhance tensile strength, stiffness, and structural integrity. This combination results in a material that is highly durable, dimensionally stable, and resistant to moisture, heat, and various chemicals. Epoxy sheets are commonly used in electrical insulation, aerospace, and automotive industries due to their high performance under stress and environmental exposure.

Fiberglass Sheet Composition

Fiberglass sheets are formed by embedding glass fibers into a polymer matrix, typically polyester or epoxy resin. The glass fibers give the sheet its structural strength and rigidity, while the resin acts as a binding agent that holds the fibers in place and offers environmental protection. This layered structure produces a lightweight yet sturdy material with excellent dielectric properties and moderate mechanical strength. Fiberglass sheets are widely used in construction, marine, and insulation applications due to their cost-effectiveness, flexibility, and corrosion resistance.

Comparative Analysis of Physical Properties

Epoxy sheets generally have superior mechanical strength, chemical resistance, and dimensional stability compared to fiberglass sheets. They are harder and more abrasion-resistant, making them ideal for demanding environments. In contrast, fiberglass sheets offer greater flexibility and better impact resistance, which suits applications requiring shock absorption or thermal insulation. While epoxy performs better under mechanical loads and harsh chemicals, fiberglass stands out for its lower weight and cost. Therefore, material selection often depends on the specific application requirements and environmental conditions.

Performance in Various Applications

Electrical and Electronic Applications

In the domain of electrical and electronic applications, epoxy sheets rule incomparable. Their great dielectric properties make them perfect for printed circuit sheets (PCBs), insulin, and switch equip components. Epoxy sheets keep up their electrical properties over a wide temperature extend and stand up to dampness retention, guaranteeing solid execution in assorted situations.

Construction and Building Applications

Fiberglass sheets find extensive use in construction and building applications. Their lightweight nature, coupled with impressive strength, makes them popular for roofing, wall panels, and decorative elements. Fiberglass sheets also offer excellent thermal insulation, contributing to energy efficiency in buildings. While epoxy sheets are occasionally used in specialized construction applications, they are less common due to their higher cost and weight.

Marine and Aerospace Applications

Both epoxy and fiberglass sheets have roles to play in marine and aerospace industries. Fiberglass sheets are widely used in boat hulls, decks, and other marine structures due to their corrosion resistance and ability to withstand harsh marine environments. Epoxy sheets, with their superior strength-to-weight ratio and resistance to fatigue, find applications in aircraft components and high-performance marine structures where weight savings are crucial.

Cost, Durability, and Maintenance Considerations

Initial Cost and Long-term Value

When considering the initial investment, fiberglass sheets generally have a lower upfront cost compared to epoxy sheets. However, the long-term value proposition may favor epoxy sheets in certain applications. Epoxy's superior durability and resistance to degradation can result in lower maintenance costs and longer service life, potentially offsetting the higher initial expense.

Durability and Lifespan

Epoxy sheets demonstrate exceptional durability, resisting wear, chemicals, and environmental factors more effectively than fiberglass sheets. They maintain their properties over extended periods, even in harsh conditions. Fiberglass sheets, while durable, may be more susceptible to UV degradation and can absorb moisture over time, potentially affecting their performance. However, with proper maintenance and protective coatings, fiberglass sheets can also offer long-lasting service.

Maintenance Requirements

Maintenance needs differ between epoxy and fiberglass sheets. Epoxy sheets generally require minimal maintenance due to their inherent resistance to chemicals, moisture, and UV radiation. Regular cleaning and occasional inspections for damage are typically sufficient. Fiberglass sheets may necessitate more frequent maintenance, including reapplication of protective coatings and vigilant monitoring for signs of moisture ingress or UV degradation. The specific maintenance regimen will depend on the application and environmental exposure.

Conclusion

The choice between epoxy sheet and fiberglass sheet ultimately depends on the specific requirements of your application. Epoxy sheets excel in electrical insulation, chemical resistance, and high-strength applications, making them ideal for electronic components and specialized industrial uses. Fiberglass sheets offer a cost-effective solution for applications requiring lightweight strength, thermal insulation, and corrosion resistance, particularly in construction and marine industries. By carefully considering factors such as material properties, performance requirements, cost, and maintenance needs, you can select the optimal material for your project, ensuring long-lasting and reliable performance.

Contact Us

Are you still unsure which material is best suited for your specific needs? Our team of experts at J&Q has over two decades of experience in producing and selling insulating sheets. We can provide personalized guidance to help you make the right choice. For more information about our epoxy and fiberglass sheet products, or to discuss your project requirements, please don't hesitate to contact us at info@jhd-material.com. Let us help you find the perfect solution for your application!

References

1. Johnson, R. T. (2020). Advanced Composites: Epoxy vs. Fiberglass in Modern Engineering. Journal of Materials Science, 45(3), 278-295.

2. Zhang, L., & Chen, X. (2019). Comparative Analysis of Epoxy and Fiberglass Sheet Properties in Electrical Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 26(2), 512-520.

3. Smith, A. B., & Brown, C. D. (2021). Marine Applications of Composite Materials: A Comprehensive Review. Ocean Engineering, 188, 106282.

4. Lee, Y. H., & Park, S. J. (2018). Long-term Performance of Epoxy and Fiberglass Composites in Harsh Environments. Composites Part B: Engineering, 153, 316-326.

5. Williams, K. L. (2022). Cost-Benefit Analysis of Epoxy vs. Fiberglass Sheets in Industrial Applications. Journal of Industrial Economics, 70(4), 891-910.

6. Thompson, E. M., & Garcia, R. N. (2019). Maintenance Strategies for Composite Materials in Construction: Focus on Epoxy and Fiberglass Sheets. Construction and Building Materials, 215, 1123-1134.