What Are the Standards for 3240 Epoxy Board Manufacturing?

2025-06-09 16:51:08

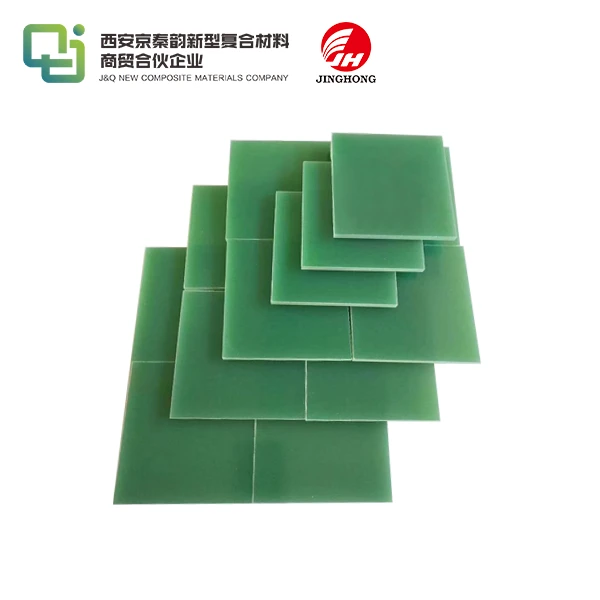

The standards for 3240 epoxy board manufacturing encompass a range of specifications and quality control measures to ensure the production of high-performance insulating materials. These standards typically include requirements for raw material selection, manufacturing processes, and final product characteristics. Key aspects often involve the epoxy resin composition, glass cloth reinforcement quality, curing conditions, and dimensional tolerances. Manufacturers must adhere to strict guidelines for thermal resistance, dielectric strength, and mechanical properties. Additionally, standards may dictate testing procedures for factors such as water absorption, flammability, and chemical resistance. Compliance with international standards like IEC, NEMA, or MIL-I-24768 is crucial for ensuring the reliability and consistency of 3240 epoxy boards across various industrial applications.

Raw Material Selection and Composition

Epoxy Resin Systems

The foundation of 3240 epoxy board manufacturing lies in the careful selection of epoxy resin systems. These systems typically consist of a base resin and a hardener, which when combined, create a thermoset polymer with exceptional electrical and mechanical properties. Manufacturers must adhere to strict standards regarding the purity, viscosity, and reactivity of these components. The epoxy resin system selected for 3240 boards often includes flame retardant additives to enhance the material's fire resistance properties without compromising its electrical insulation characteristics.

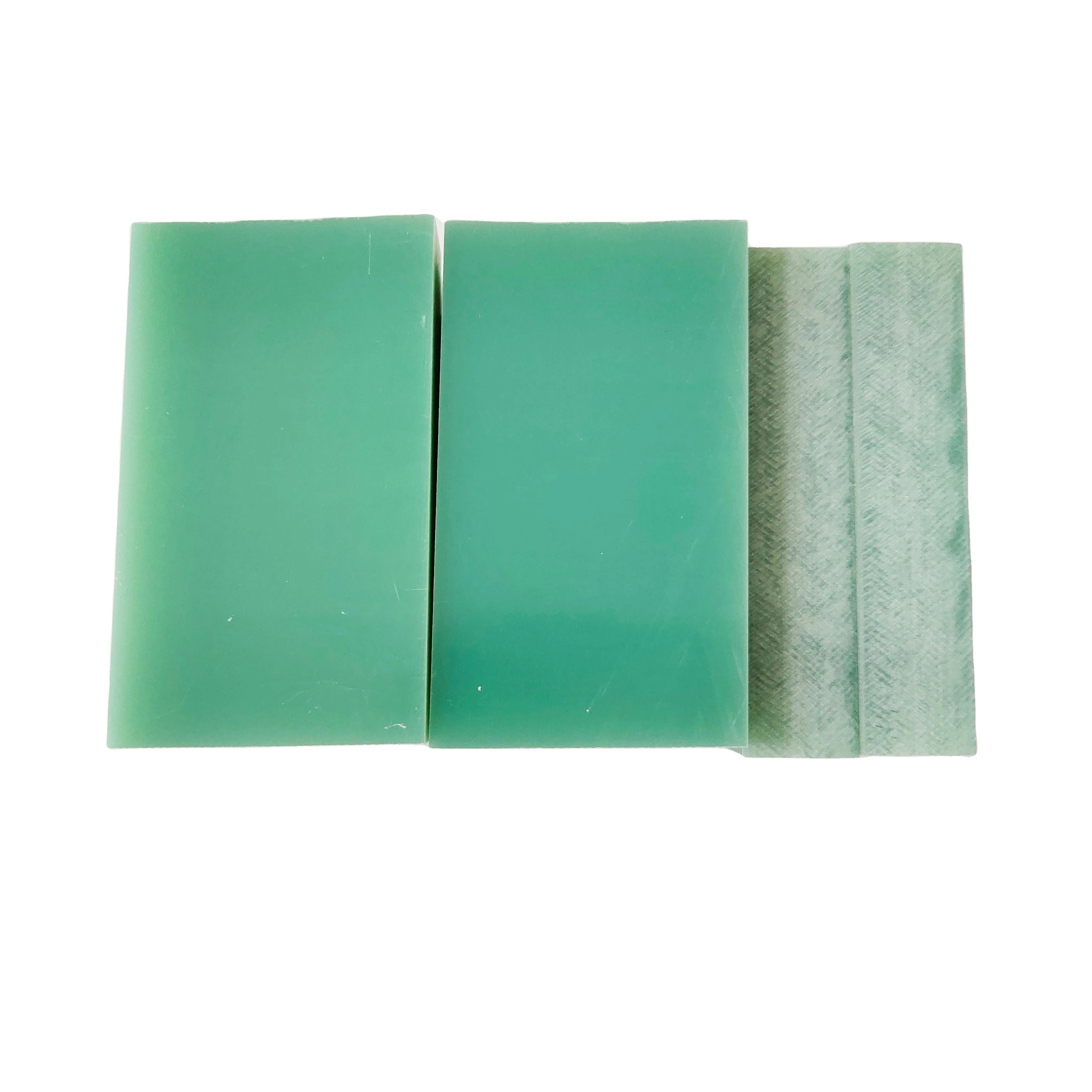

Glass Cloth Reinforcement

High-quality glass cloth serves as the reinforcement material in 3240 epoxy boards. Standards dictate the type of glass fibers used, typically E-glass due to its excellent electrical and mechanical properties. The weave pattern, thread count, and thickness of the glass cloth are carefully controlled to ensure uniform reinforcement throughout the board. Manufacturers must verify that the glass cloth meets specifications for tensile strength, dielectric constant, and chemical compatibility with the epoxy resin system.

Filler Materials

Inorganic fillers are often incorporated into 3240 epoxy boards to enhance specific properties. These fillers must meet stringent purity standards and particle size distributions. Common fillers include silica, alumina, or calcium carbonate, each selected for their ability to improve thermal conductivity, reduce thermal expansion, or enhance flame retardancy. The precise blend and proportion of fillers are critical in achieving the desired performance characteristics of the final product.

Manufacturing Process Controls

Prepreg Preparation

The manufacturing of 3240 epoxy boards begins with the preparation of prepregs, which are sheets of glass cloth impregnated with partially cured epoxy resin. This process requires precise control of resin content, typically maintained within a narrow range of 35-45% by weight. Temperature and pressure during impregnation must be carefully regulated to ensure even distribution of resin throughout the glass cloth. Standards specify acceptable variations in resin content and the degree of pre-cure, as these factors significantly influence the final board properties.

Lamination and Pressing

The lamination process involves stacking multiple layers of prepreg and subjecting them to heat and pressure. Standards for 3240 epoxy board manufacturing dictate specific temperature profiles and pressure cycles to achieve optimal curing and bonding between layers. Typical pressing temperatures range from 150°C to 180°C, with pressures exceeding 1000 psi. The duration of the pressing cycle is critical and must be precisely controlled to ensure complete cure without degrading the resin system. Manufacturers must maintain detailed records of pressing parameters for quality assurance purposes.

Post-Curing and Conditioning

After the initial pressing, 3240 epoxy boards undergo a post-curing process to achieve maximum cross-linking of the epoxy resin. This step is crucial for developing the board's full mechanical and electrical properties. Standards specify post-cure temperatures, typically between 150°C and 200°C, and durations that can extend from several hours to days, depending on the specific formulation. Following post-cure, boards must be conditioned in a controlled environment to stabilize their dimensions and properties before final testing and inspection.

Quality Control and Testing Standards

Dimensional and Physical Properties

Rigorous quality control measures are implemented to ensure 3240 epoxy boards meet stringent dimensional and physical property standards. Thickness tolerances are typically held to ±10% of the nominal thickness, with tighter tolerances available for specialized applications. Warpage and bow are closely monitored, with maximum allowable deviations specified based on board size and thickness. Surface finish requirements dictate a smooth, uniform appearance free from defects such as pits, blisters, or foreign inclusions. Density measurements are performed to verify proper consolidation and resin content.

Electrical Properties Testing

The electrical properties of 3240 epoxy boards are paramount to their performance in insulating applications. Standard tests include dielectric strength measurements, typically requiring values exceeding 40 kV/mm when tested per IEC 60243-1. Volume and surface resistivity tests are conducted to ensure values meet or exceed 1014 ohm-cm and 1013 ohms, respectively. Dissipation factor and dielectric constant are measured across a range of frequencies, with typical values for dissipation factor being less than 0.02 at 1 MHz. Arc resistance testing is performed to verify the board's ability to withstand electrical discharges without surface tracking.

Thermal and Mechanical Testing

Thermal performance is a critical aspect of 3240 epoxy board standards. Glass transition temperature (Tg) measurements, typically using differential scanning calorimetry (DSC), must demonstrate values above 130°C for standard grades and can exceed 180°C for high-temperature variants. Coefficient of thermal expansion (CTE) is measured in both the x-y plane and z-axis, with values generally falling below 50 ppm/°C in the x-y direction. Mechanical testing includes flexural strength and modulus measurements, with minimum values often specified at 300 MPa and 20 GPa, respectively. Impact resistance and bond strength between layers are also evaluated to ensure the board's structural integrity under various environmental conditions.

Conclusion

The standards for 3240 epoxy board manufacturing encompass a comprehensive set of requirements that ensure the production of high-quality, reliable insulating materials. From meticulous raw material selection to stringent process controls and exhaustive quality testing, these standards guarantee that 3240 epoxy boards meet the demanding needs of electrical and electronic applications. By adhering to these rigorous guidelines, manufacturers can produce boards with consistent properties, excellent electrical insulation, and superior mechanical performance, suitable for use in a wide range of industries where reliability and precision are paramount.

Contact Us

For more information about our 3240 epoxy board products and how they meet or exceed industry standards, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulating solution for your specific needs.

References

1. International Electrotechnical Commission. (2021). IEC 61249-2-7: Materials for printed boards and other interconnecting structures - Part 2-7: Reinforced base materials clad and unclad - Epoxide cellulose paper/woven E-glass reinforced laminate sheets of defined flammability (vertical burning test), copper-clad.

2. National Electrical Manufacturers Association. (2019). NEMA LI 1: Industrial Laminated Thermosetting Products.

3. Department of Defense. (2018). MIL-I-24768: Insulation, Plastics, Laminated, Thermosetting, General Specification for.

4. American Society for Testing and Materials. (2020). ASTM D5470: Standard Test Method for Thermal Transmission Properties of Thermally Conductive Electrical Insulation Materials.

5. Institute for Interconnecting and Packaging Electronic Circuits. (2022). IPC-4101: Specification for Base Materials for Rigid and Multilayer Printed Boards.

6. Underwriters Laboratories. (2021). UL 94: Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances.