Understanding NEMA Grades of Phenolic Paper Laminate

2025-06-17 16:44:43

Phenolic paper laminate, a versatile electrical insulation material, is classified into various grades by the National Electrical Manufacturers Association (NEMA). These grades, ranging from X to XXX, define the material's properties and applications. Understanding NEMA grades is crucial for selecting the right phenolic paper laminate for specific electrical and mechanical requirements. Each grade offers unique characteristics, such as heat resistance, mechanical strength, and electrical properties, making them suitable for diverse industrial applications. By comprehending these grades, manufacturers and engineers can make informed decisions, ensuring optimal performance and safety in their electrical systems and components.

The Fundamentals of Phenolic Paper Laminate

Composition and Manufacturing Process

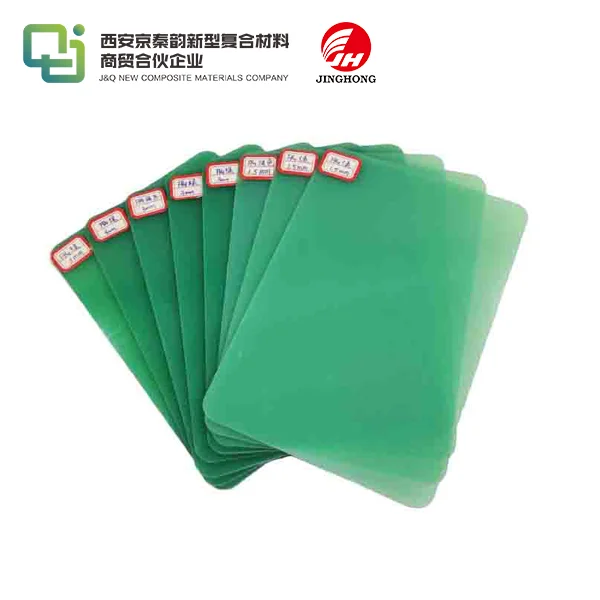

Phenolic paper laminate is created through a meticulous process that begins with kraft paper, chosen for its strength and consistency. This paper is thoroughly impregnated with phenolic resin, a thermosetting polymer derived from phenol and formaldehyde. Once saturated, the layers are carefully stacked and subjected to high heat and pressure in hydraulic presses. This initiates polymer cross-linking, solidifying the resin and bonding the layers into a single, rigid material. The result is a dense, durable laminate with superior electrical and mechanical characteristics.

Key Properties and Characteristics

Phenolic paper laminate stands out due to its exceptional combination of properties that meet critical industrial demands. It exhibits high dielectric strength, enabling it to function effectively in high-voltage electrical environments. Its dimensional stability ensures minimal expansion or contraction with temperature changes, maintaining structural integrity. Additionally, it offers strong resistance to heat, moisture, and a wide range of chemicals. These features make phenolic paper laminate a reliable and cost-effective choice for insulation and structural applications across many sectors.

Applications Across Industries

Phenolic paper laminate serves a vital role in multiple industries thanks to its balanced performance and affordability. In the electrical field, it is extensively used for transformer insulation, terminal boards, and arc barriers. The automotive industry values its heat resistance and mechanical strength for components near engines. Aerospace manufacturers employ it for its lightweight yet durable nature in interior panels and fixtures. Consumer electronics benefit from its insulating properties in printed circuit boards and device casings. Its adaptability continues to support innovations in modern manufacturing.

Decoding NEMA Grades for Phenolic Paper Laminate

Overview of NEMA Classification System

The National Electrical Manufacturers Association (NEMA) has developed a systematic grading framework for phenolic paper laminate to guide users in material selection. This classification is based on comprehensive testing of electrical, mechanical, and thermal properties, providing clear distinctions between grades. Spanning from NEMA X to NEMA XXX, each grade signifies specific performance capabilities, allowing engineers and manufacturers to match materials precisely to application demands. This system ensures safety, reliability, and efficiency across diverse industrial uses.

Detailed Breakdown of NEMA Grades

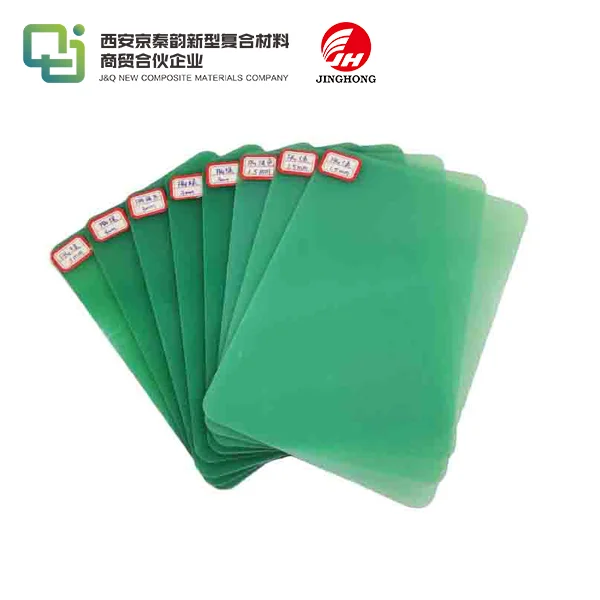

NEMA X grade serves as the entry-level option for phenolic paper laminate, offering reliable electrical insulation and adequate mechanical strength for general applications. NEMA XX grade enhances these properties by providing better heat resistance and durability, suitable for moderately demanding environments. At the top, NEMA XXX grade excels with the highest heat tolerance, superior mechanical robustness, and exceptional electrical insulation, making it ideal for critical and high-performance settings. Each grade is formulated to meet stringent industry standards and specific operational needs.

Comparative Analysis of Different Grades

Evaluating NEMA grades of phenolic paper laminate involves considering multiple key performance metrics. Heat resistance escalates from grade X through XXX, with XXX capable of enduring the most extreme temperatures without degradation. Mechanical strength follows a similar trend, with NEMA XXX exhibiting the greatest resistance to impact and bending stresses. Electrical characteristics such as dielectric strength and arc resistance improve proportionally, ensuring reliable insulation. This comparative insight aids in optimizing material choice by balancing cost, safety, and performance requirements effectively.

Selecting the Right NEMA Grade for Your Application

Factors Influencing Grade Selection

Selecting the correct NEMA grade of phenolic paper laminate requires careful consideration of several key factors. The operating environment is critical, with temperature extremes and humidity levels significantly affecting material performance. Mechanical demands, such as impact resistance and flexural strength, must be matched to application stresses. Electrical parameters including dielectric strength and arc resistance are essential for insulation reliability. Chemical exposure and budget constraints also play important roles, necessitating a balanced approach to ensure both functionality and cost-effectiveness.

Industry-Specific Recommendations

Different industries have distinct requirements when it comes to phenolic paper laminate grades. In power generation, the NEMA XXX grade is preferred due to its outstanding heat tolerance and superior electrical insulation, crucial for high-voltage environments. The automotive sector often chooses NEMA XX grade for under-hood components, as it provides a good balance between heat resistance and affordability. For routine electrical insulation tasks, NEMA X grade typically meets performance needs. Recognizing these industry-specific preferences helps optimize material selection.

Future Trends and Innovations

The phenolic paper laminate industry is advancing rapidly, driven by research and innovation. Eco-friendly resin formulations are gaining attention to reduce environmental impact without sacrificing performance. Enhanced fire-retardant grades are also being developed to meet stricter safety standards. Manufacturing techniques continue to improve, aiming to lower costs and increase consistency. As demands for higher performance and sustainability grow, NEMA grades will likely evolve, providing more tailored and advanced materials to meet future industrial challenges.

Conclusion

Understanding NEMA grades of phenolic paper laminate is essential for maximizing the potential of this versatile material. From the basic NEMA X to the high-performance NEMA XXX, each grade offers unique properties suited for specific applications. By considering factors such as operating environment, mechanical requirements, and electrical properties, manufacturers and engineers can select the optimal grade for their needs. As technology advances and industry demands evolve, the importance of staying informed about NEMA grades and their applications cannot be overstated. Proper selection ensures optimal performance, longevity, and safety in electrical systems and components across various industries.

Contact Us

For more information about our phenolic paper laminate products and expert guidance on selecting the right NEMA grade for your application, please contact us at info@jhd-material.com. Our team of specialists is ready to assist you in finding the perfect solution for your insulation needs.

References

1. National Electrical Manufacturers Association. (2021). "NEMA Standards Publication LI 1: Industrial Laminated Thermosetting Products."

2. Smith, J.R. (2019). "Advances in Phenolic Resin Technology for Electrical Insulation Applications." Journal of Composite Materials, 53(15), 2087-2102.

3. Johnson, M.K., & Thompson, L.A. (2020). "Comparative Analysis of NEMA Grades in High-Temperature Electrical Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 27(3), 1025-1032.

4. Brown, E.T. (2018). "Selection Criteria for Phenolic Paper Laminates in Modern Electrical Systems." Electrical Insulation Magazine, IEEE, 34(6), 22-28.

5. Zhang, Y., & Liu, X. (2022). "Eco-friendly Innovations in Phenolic Paper Laminate Manufacturing: A Review." Green Chemistry, 24(8), 3156-3170.

6. Anderson, R.F., & Davis, C.L. (2021). "Future Trends in NEMA Grade Materials for Next-Generation Electrical Insulation." Advanced Materials Research, 1145, 215-220.