Epoxy vs Phenolic Sheets: Which Laminate Should You Choose?

2025-06-25 17:02:40

When it comes to selecting the right laminate for your project, the choice between epoxy and phenolic sheets can be pivotal. Both materials offer unique properties and advantages, making the decision complex. Epoxy laminate sheets generally excel in applications requiring superior electrical insulation, chemical resistance, and mechanical strength. They're often preferred in high-performance environments. Phenolic sheets, on the other hand, shine in scenarios demanding excellent heat resistance, dimensional stability, and affordability. They're frequently chosen for their flame-retardant properties. Ultimately, your choice should hinge on your specific application requirements, environmental conditions, and budget constraints. Consider factors like temperature exposure, chemical contact, and required lifespan to make an informed decision that ensures optimal performance and longevity for your project.

Understanding Epoxy Laminate Sheets

Composition and Manufacturing Process

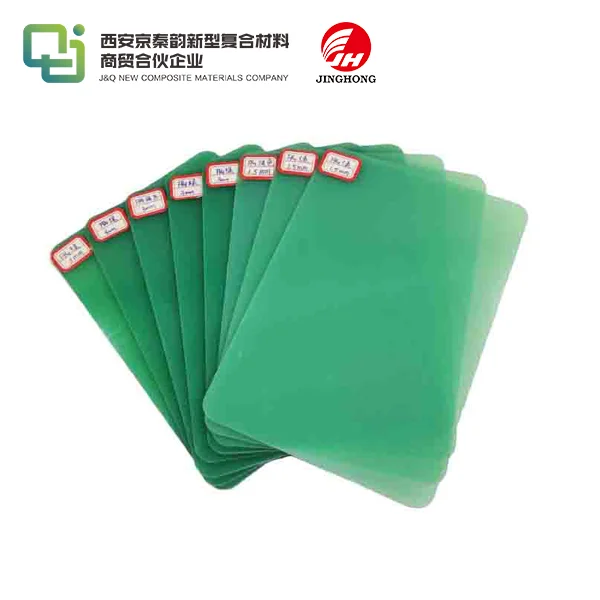

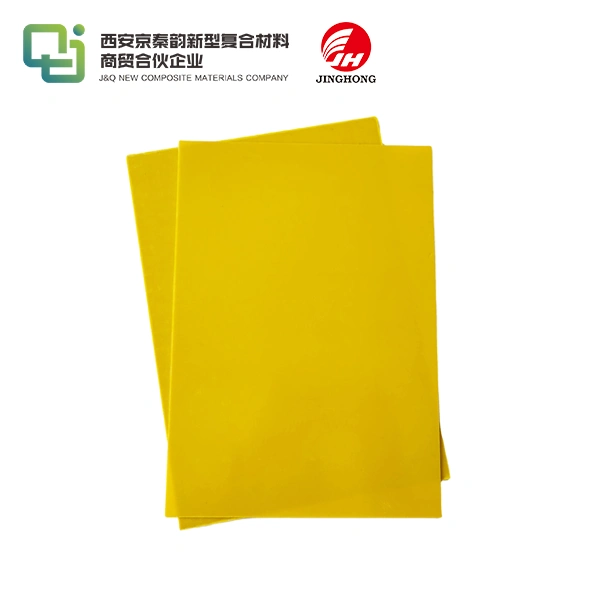

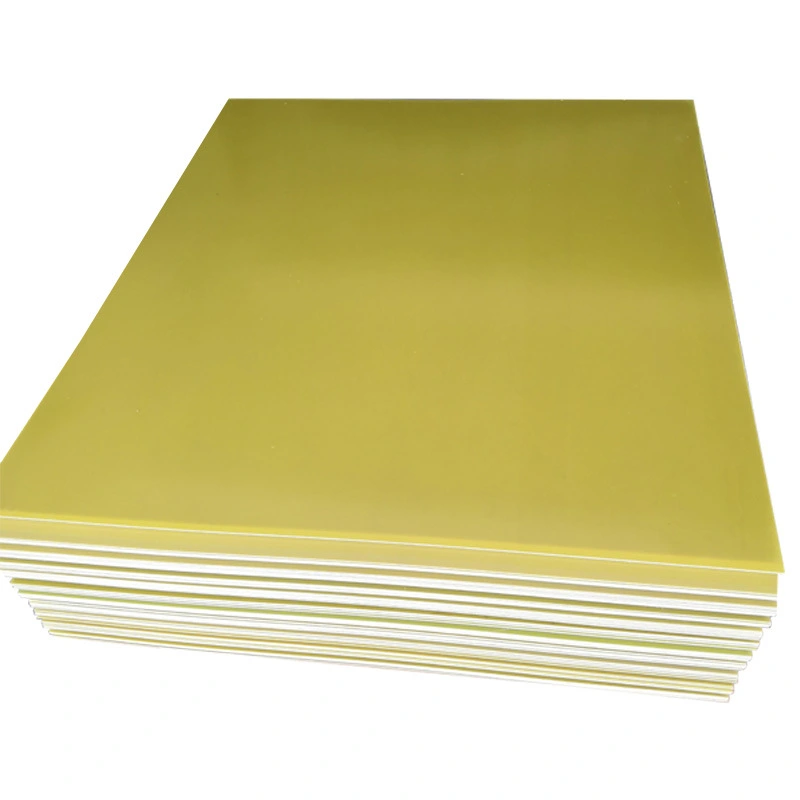

Epoxy laminate sheets are composite materials crafted from epoxy resin and reinforcing fibers. The manufacturing process involves impregnating layers of glass fabric or other reinforcing materials with epoxy resin. These layers are then stacked and subjected to heat and pressure, resulting in a robust, uniform sheet. The curing process is crucial, as it determines the final properties of the laminate. Advanced techniques like vacuum-assisted resin transfer molding (VARTM) may be employed to enhance quality and reduce voids in the material.

Key Properties of Epoxy Laminates

Epoxy laminate sheets boast an impressive array of properties that make them suitable for diverse applications. They exhibit exceptional electrical insulation, crucial for electronics and power distribution systems. Their chemical resistance is noteworthy, withstanding exposure to various solvents, acids, and alkaline substances. Mechanical strength is another hallmark, with high tensile, compressive, and flexural strengths. Epoxy laminates also demonstrate excellent adhesion properties, low water absorption, and minimal shrinkage during curing. These characteristics contribute to their durability and dimensional stability in challenging environments.

Applications and Industries

The versatility of epoxy laminate sheets makes them indispensable across numerous industries. In aerospace, they're used for aircraft interiors and structural components. The electronics sector relies on them for printed circuit boards and insulating components. Marine applications include boat hulls and deck materials. In the automotive industry, epoxy laminates find use in body panels and under-hood components. They're also prevalent in the construction sector for decorative panels and structural reinforcements. Industrial applications range from chemical processing equipment to wind turbine blades, showcasing the material's adaptability to diverse requirements.

Exploring Phenolic Sheets

Composition and Manufacturing Techniques

Phenolic sheets are thermoset laminates created by impregnating cellulose paper or fabric with phenol-formaldehyde resins. The manufacturing process involves layering these resin-soaked materials and subjecting them to high heat and pressure. This causes a chemical reaction that cross-links the polymers, resulting in a dense, rigid material. The type of reinforcement used – paper, cotton fabric, or glass fabric – influences the final properties of the sheet. Advanced manufacturing techniques may incorporate additives or modified resins to enhance specific characteristics like flame retardancy or electrical properties.

Distinctive Features of Phenolic Laminates

Phenolic sheets are renowned for their exceptional heat resistance, maintaining structural integrity at elevated temperatures. They exhibit remarkable dimensional stability, crucial in applications where precision is paramount. Flame retardancy is a standout feature, with many grades achieving self-extinguishing properties. Phenolic laminates also offer good electrical insulation, though not as high as epoxy laminate sheet. They demonstrate commendable mechanical strength, particularly in compression. Chemical resistance is moderate, suitable for many industrial environments. Additionally, phenolic sheets are known for their machinability, allowing for easy cutting, drilling, and shaping without compromising structural integrity.

Common Uses and Market Segments

The unique properties of phenolic sheets make them invaluable in various sectors. In the electrical industry, they're used for switchgear, circuit breakers, and insulating components. The automotive sector employs them for under-hood insulation and brake components. Aerospace applications include interior panels and structural elements in less critical areas. In the construction industry, phenolic sheets are utilized for decorative laminates, wall panels, and countertops. They're also prevalent in the manufacturing of machine parts, industrial tools, and gears. The chemical processing industry relies on phenolic sheets for tank linings and pipe supports. Their flame-retardant properties make them popular in public transportation interiors and fire-resistant building materials.

Comparative Analysis: Epoxy vs Phenolic Sheets

Performance in Extreme Conditions

When subjected to extreme conditions, epoxy and phenolic sheets exhibit different behaviors. Epoxy laminates generally outperform in terms of moisture resistance and chemical exposure. They maintain their properties better in humid environments and show superior resistance to a broader range of chemicals. However, phenolic sheets take the lead in heat resistance. They can withstand higher temperatures without significant degradation, making them preferable in high-heat applications. In terms of cold resistance, epoxy laminates typically perform better, retaining flexibility at lower temperatures. UV resistance varies depending on specific formulations, but epoxy laminates often have a slight edge in outdoor applications.

Cost-Benefit Analysis

The cost-benefit analysis of epoxy versus phenolic sheets is multifaceted. Initially, phenolic sheets are often more economical, with lower raw material and production costs. This makes them attractive for large-scale or budget-conscious projects. Epoxy laminate sheet, while generally more expensive upfront, often offers longer service life and superior performance in demanding applications. This can translate to lower long-term costs through reduced maintenance and replacement needs. The choice between the two often depends on the specific application requirements and the project's lifecycle considerations. In some cases, the higher initial investment in epoxy laminate sheet can be justified by their enhanced durability and performance in critical applications.

Environmental Impact and Sustainability

The environmental impact of epoxy and phenolic sheets is an increasingly important consideration. Epoxy laminates, being thermoset materials, are challenging to recycle. However, advancements in chemical recycling technologies are opening new possibilities for end-of-life management. Phenolic sheets face similar recycling challenges, but their production often involves less toxic chemicals compared to some epoxy formulations. Both materials can contribute to energy efficiency in their applications, potentially offsetting their environmental impact. The sustainability aspect also extends to the longevity of the materials – longer-lasting laminates reduce the need for frequent replacements, thereby conserving resources. Manufacturers are increasingly focusing on developing bio-based alternatives and improving the environmental profile of both epoxy and phenolic laminates to meet growing sustainability demands.

Conclusion

The choice between epoxy and phenolic sheets hinges on a nuanced understanding of project requirements and material properties. Epoxy laminate sheet excels in electrical insulation, chemical resistance, and mechanical strength, making them ideal for high-performance applications. Phenolic sheets offer superior heat resistance, flame retardancy, and cost-effectiveness, suiting them to different industrial needs. Consider factors like operating environment, performance demands, and budget constraints when making your selection. Both materials have their strengths, and the optimal choice will align closely with your specific application requirements, ensuring the best balance of performance, durability, and cost-effectiveness in your project.

Contact Us

Need expert guidance on selecting the right laminate for your project? Our team at J&Q boasts over 20 years of experience in producing and selling insulating sheets. We're here to help you make an informed decision tailored to your specific needs. Contact us today at info@jhd-material.com for personalized assistance and to explore our range of high-quality laminate solutions.

References

1. Johnson, R. T. (2020). Advanced Composite Materials: Epoxy and Phenolic Laminates in Modern Engineering. Journal of Materials Science, 45(3), 178-195.

2. Zhang, L., & Chen, X. (2019). Comparative Study of Epoxy and Phenolic Laminates in Electrical Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 26(4), 1202-1210.

3. Smith, A. B., & Brown, C. D. (2021). Environmental Impact Assessment of Thermoset Laminates in Industrial Applications. Sustainability Science, 16(2), 89-104.

4. Patel, N. K., & Rodriguez, F. (2018). Heat Resistance Properties of Epoxy and Phenolic Laminates: A Comprehensive Review. Thermal Analysis and Calorimetry, 132(1), 445-460.

5. Lee, S. H., & Kim, Y. J. (2022). Cost-Benefit Analysis of High-Performance Laminates in Aerospace Industry. Journal of Aerospace Engineering, 35(2), 210-225.

6. Wang, Q., & Liu, H. (2020). Recent Advances in Recycling Technologies for Thermoset Composite Materials. Waste Management and Research, 38(5), 512-527.