Can You Use FR4 Epoxy Fiberglass Sheets in DIY Electronics?

2025-07-04 16:58:48

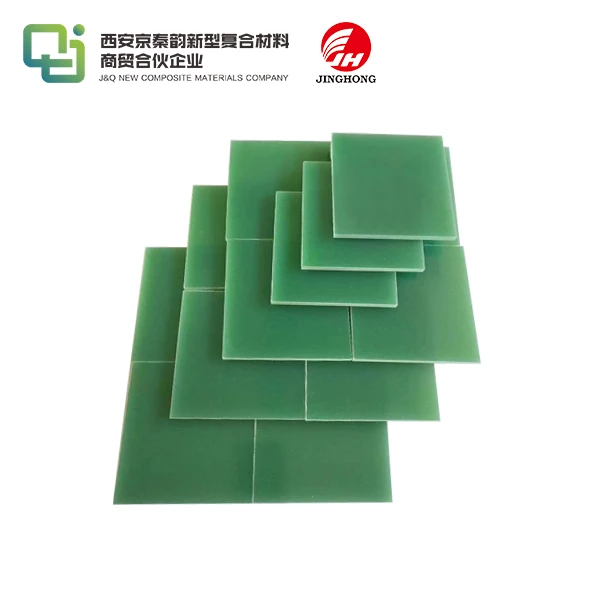

FR4 epoxy fiberglass sheets are an excellent choice for DIY electronics projects. These versatile materials combine the strength of fiberglass with the electrical insulation properties of epoxy resin, making them ideal for circuit boards and other electronic applications. FR4 epoxy glass sheets offer high thermal stability, excellent dimensional stability, and superior electrical insulation, all of which are crucial for creating reliable and durable electronic devices. Whether you're a hobbyist or a professional, incorporating FR4 epoxy fiberglass sheets into your DIY electronics projects can significantly enhance the quality and longevity of your creations. Let's delve deeper into the world of FR4 epoxy fiberglass sheets and explore their applications in DIY electronics.

Understanding FR4 Epoxy Fiberglass Sheets

Composition and Manufacturing Process

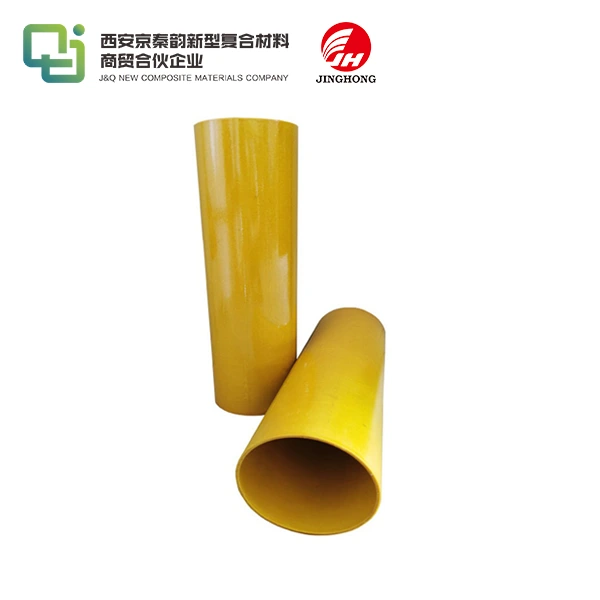

FR4 epoxy fiberglass sheets are composite materials consisting of woven fiberglass cloth impregnated with epoxy resin. The manufacturing process involves layering multiple sheets of fiberglass fabric and saturating them with epoxy resin. This combination is then subjected to heat and pressure, resulting in a rigid, durable material with excellent electrical and mechanical properties. The "FR" in FR4 stands for "Flame Retardant," indicating that these sheets have been treated to resist combustion, a crucial safety feature for electronic applications.

Key Properties of FR4 Epoxy Glass Sheets

FR4 epoxy glass sheets boast an impressive array of properties that make them indispensable in electronics. They exhibit exceptional electrical insulation, with a dielectric strength that can withstand high voltages without breakdown. Their low moisture absorption rate ensures stability in varying environmental conditions. Moreover, FR4 sheets maintain their mechanical strength and dimensional stability across a wide temperature range, making them suitable for diverse applications. The material's relatively low cost and ease of machining further contribute to its popularity in both professional and DIY electronics projects.

Grades and Variations of FR4 Epoxy Fiberglass Sheets

FR4 epoxy fiberglass sheets come in various grades and variations to suit different applications. Standard FR4 is the most common, but there are also high-temperature grades for more demanding environments. Some variations include halogen-free FR4 for environmentally sensitive applications and high-frequency FR4 for use in high-speed digital or RF circuits. The thickness of FR4 sheets can range from thin flexible sheets to rigid boards several millimeters thick. Understanding these variations allows DIY enthusiasts to choose the most appropriate FR4 epoxy glass sheet for their specific project requirements.

Applications of FR4 Epoxy Fiberglass Sheets in DIY Electronics

Printed Circuit Board (PCB) Fabrication

One of the most common applications of FR4 epoxy fiberglass sheets in DIY electronics is the fabrication of printed circuit boards (PCBs). These sheets serve as the substrate upon which conductive copper traces are etched to create circuits. DIY enthusiasts can purchase copper-clad FR4 sheets and use various methods, such as photo etching or CNC milling, to create custom PCBs. The stability and insulation properties of FR4 ensure that the resulting PCBs are reliable and durable, capable of withstanding the rigors of electronic operation.

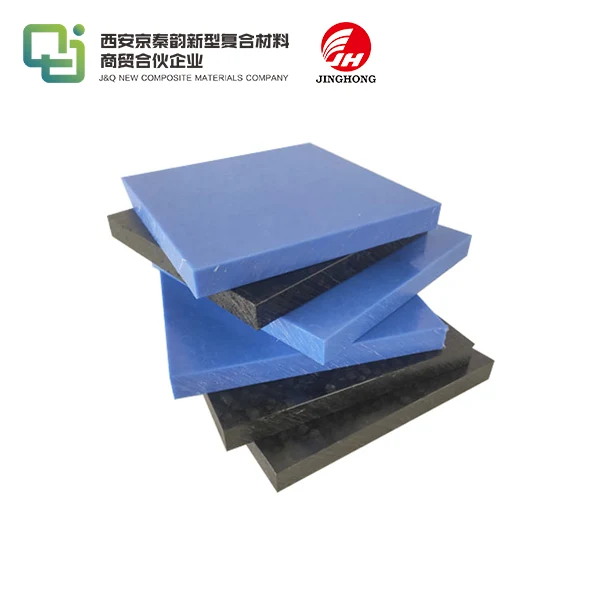

Enclosure and Panel Construction

FR4 epoxy glass sheets are excellent materials for constructing enclosures and panels for electronic projects. Their strength, rigidity, and ease of machining make them ideal for creating custom housings for DIY devices. These sheets can be easily cut, drilled, and shaped using common tools, allowing hobbyists to craft professional-looking enclosures. The flame-retardant properties of FR4 also provide an added layer of safety for electronic devices, making them particularly suitable for projects that may generate heat or be exposed to potential ignition sources.

Insulation and Separation in Complex Assemblies

In more complex DIY electronic assemblies, FR4 epoxy fiberglass sheets can be used as insulation layers or separators between different components or circuit sections. Their excellent dielectric properties prevent unwanted electrical interactions, while their thermal stability ensures that they maintain their insulating properties even in high-temperature environments. This application is particularly useful in multi-layer designs or in projects where different voltage levels or signal types need to be isolated from each other to prevent interference or short circuits.

Tips for Working with FR4 Epoxy Fiberglass Sheets in DIY Projects

Proper Cutting and Machining Techniques

When working with FR4 epoxy glass sheets, using the right cutting and machining techniques is crucial. For straight cuts, a fine-toothed saw or a scoring tool followed by careful breaking along the score line can be effective. For more precise or complex shapes, a CNC router or laser cutter yields the best results. When drilling, use sharp, high-speed steel or carbide bits, and apply light pressure to prevent delamination. Always wear appropriate safety gear, including eye protection and a dust mask, as machining FR4 can produce fine, potentially harmful particles.

Handling and Storage Considerations

Proper handling and storage of FR4 epoxy fiberglass sheets are essential to maintain their quality and performance. Store sheets flat in a cool, dry environment to prevent warping or moisture absorption. When handling, avoid bending or flexing the sheets excessively, as this can cause stress or delamination. If working with copper-clad FR4 for PCB fabrication, handle the sheets by the edges to avoid contaminating the copper surface with oils from your skin, which can interfere with etching or soldering processes.

Design Considerations for Optimal Performance

When designing projects using FR4 epoxy glass sheets, consider the material's properties to optimize performance. For PCB designs, account for the dielectric constant of FR4 when calculating trace widths and spacing for impedance-controlled circuits. In enclosure designs, factor in the material's thermal expansion characteristics to ensure proper fit and alignment of components. For high-frequency applications, be aware of FR4's limitations and consider using specialized high-frequency grades if necessary. By understanding and working within the material's strengths and limitations, you can create more effective and reliable DIY electronic projects.

Conclusion

FR4 epoxy fiberglass sheets are a versatile and invaluable material for DIY electronics enthusiasts. Their unique combination of electrical, mechanical, and thermal properties makes them suitable for a wide range of applications, from PCB fabrication to enclosure construction. By understanding the characteristics of FR4 epoxy glass sheets and following best practices for working with them, DIY electronics hobbyists can elevate their projects to professional levels of quality and performance. As you embark on your next electronic creation, consider incorporating FR4 epoxy fiberglass sheets to enhance the durability, reliability, and sophistication of your design.

Contact Us

Ready to take your DIY electronics projects to the next level with FR4 epoxy fiberglass sheets? Contact us at info@jhd-material.com for expert advice and high-quality materials to bring your innovative ideas to life. Let's create something amazing together!

References

1. Johnson, R. (2021). Advanced Materials in DIY Electronics: A Comprehensive Guide.

2. Smith, A. et al. (2020). FR4 Epoxy Fiberglass: Properties and Applications in Modern Electronics.

3. Electronics Hobbyist Association. (2022). Best Practices for PCB Fabrication Using FR4 Materials.

4. Chen, L. (2019). Thermal Management in DIY Electronic Enclosures: Material Selection and Design.

5. Miller, K. (2021). Comparative Analysis of Substrate Materials for Amateur Radio Projects.

6. Thompson, E. (2020). Sustainability in DIY Electronics: Eco-friendly Alternatives to Traditional Materials.