Order Custom-Cut FR4 Fiberglass Sheets to Your Specs

2025-07-21 17:08:14

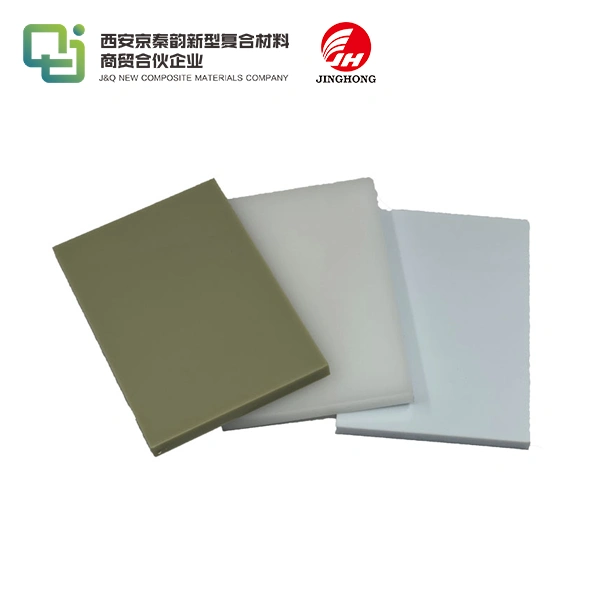

When it comes to precision engineering and electrical applications, having the right materials cut to your exact specifications can make all the difference. FR4 fiberglass sheets are a cornerstone in many industries, prized for their exceptional electrical insulation properties, mechanical strength, and flame-resistant characteristics. By ordering custom-cut FR4 fiberglass sheets, you ensure that your projects benefit from materials tailored to your unique requirements. This personalized approach not only enhances efficiency but also minimizes waste and optimizes performance. Whether you're working on circuit boards, aerospace components, or industrial machinery, custom-cut FR4 sheets provide the flexibility and precision needed to bring your designs to life with uncompromising quality.

Understanding FR4 Fiberglass Sheets and Their Applications

Composition and Properties of FR4 Fiberglass

FR4 fiberglass sheets are composite materials consisting of woven fiberglass cloth impregnated with an epoxy resin system. This combination results in a material with remarkable properties that make it indispensable in various industries. The "FR" in FR4 stands for "Flame Retardant," indicating its ability to self-extinguish when exposed to fire. This characteristic is achieved through the addition of brominated compounds to the epoxy resin.

The mechanical properties of FR4 fiberglass sheets are equally impressive. They exhibit high flexural strength, making them resistant to bending and warping. The material also boasts excellent dimensional stability, maintaining its shape and size even under varying environmental conditions. Additionally, FR4 sheets have low water absorption rates, ensuring that they retain their electrical and mechanical properties in humid environments.

From an electrical standpoint, FR4 fiberglass sheets are prized for their superior insulation characteristics. They have a high dielectric strength, which means they can withstand strong electric fields without breaking down. This property, combined with their low dielectric constant, makes FR4 an ideal substrate for high-frequency applications where signal integrity is crucial.

Industries Benefiting from FR4 Fiberglass Sheets

The versatility of FR4 fiberglass sheets makes them valuable across a wide range of industries. In the electronics sector, they serve as the primary material for printed circuit boards (PCBs), providing a stable and insulating base for electronic components. The aerospace industry relies on FR4 for various applications, including interior panels and structural components, due to its lightweight nature and flame-retardant properties.

In the automotive industry, FR4 fiberglass sheets find use in electrical systems and under-hood applications where heat resistance and electrical insulation are paramount. The material's durability and resistance to chemicals make it suitable for use in industrial machinery, particularly in environments where exposure to harsh substances is common.

The telecommunications sector benefits from FR4's excellent dielectric properties, using it in antenna substrates and high-frequency transmission equipment. In the renewable energy field, FR4 sheets play a role in solar panel construction and wind turbine components, contributing to the efficiency and longevity of these sustainable technologies.

Advantages of Custom-Cut FR4 Sheets

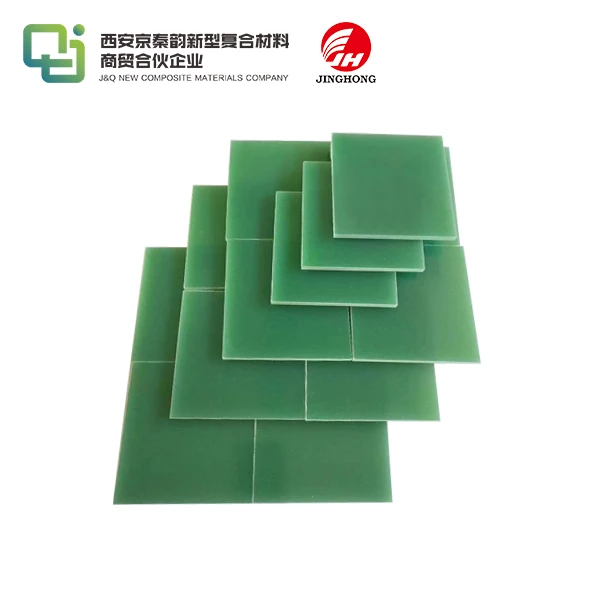

Opting for custom-cut FR4 fiberglass sheets offers numerous advantages over standard-sized sheets. Precision cutting ensures that each piece fits perfectly into your design, eliminating the need for on-site modifications and reducing material waste. This precision is particularly crucial in applications where tight tolerances are required, such as in the production of multilayer PCBs or intricate aerospace components.

Custom cutting also allows for the integration of complex shapes and features that would be challenging to achieve with standard sheets. This capability opens up new possibilities in design, enabling engineers to create more efficient and compact solutions. Moreover, by ordering sheets cut to your specifications, you can streamline your production process, reducing labor costs and minimizing the risk of errors associated with manual cutting.

Another significant advantage is the ability to optimize material usage. By ordering exactly what you need, you can reduce inventory costs and storage space requirements. This approach aligns with lean manufacturing principles, contributing to overall operational efficiency and cost-effectiveness.

The Custom-Cutting Process for FR4 Fiberglass Sheets

Advanced Cutting Technologies

The process of custom-cutting FR4 fiberglass sheets involves sophisticated technologies that ensure precision and quality. Computer Numerical Control (CNC) machining is at the forefront of these cutting methods. CNC machines use computer-programmed instructions to control cutting tools, allowing for extremely accurate and repeatable cuts. This technology is particularly valuable when producing large quantities of identical pieces or when working with complex geometries.

Laser cutting is another advanced technique used for FR4 sheets. This method employs a high-powered laser beam to cut through the material with exceptional precision. Laser cutting is ideal for creating intricate designs and can achieve very tight tolerances. The heat generated by the laser also seals the edges of the cut, preventing fraying of the fiberglass fibers.

Waterjet cutting is a versatile option that uses a high-pressure stream of water, often mixed with abrasive particles, to cut through FR4 sheets. This method is particularly useful for thicker materials and can produce clean cuts without generating heat, which can be advantageous in certain applications where thermal stress is a concern.

Ensuring Precision and Quality

Achieving the highest level of precision in custom-cut FR4 fiberglass sheets requires a meticulous approach to quality control. The process begins with careful material selection, ensuring that only the highest grade FR4 sheets are used. Before cutting, the sheets undergo thorough inspection to verify their dimensional accuracy and surface quality.

During the cutting process, advanced measurement systems continuously monitor the accuracy of cuts. These systems use lasers or optical sensors to compare the actual dimensions of cut pieces against the specified tolerances in real-time. Any deviations are immediately corrected, ensuring consistency across the entire production run.

Post-cutting quality assurance involves rigorous inspection procedures. Each cut piece is carefully examined for dimensional accuracy, edge quality, and surface finish. Sophisticated imaging systems and precision measurement tools are employed to detect even the slightest imperfections. Any pieces that do not meet the stringent quality standards are rejected and recycled.

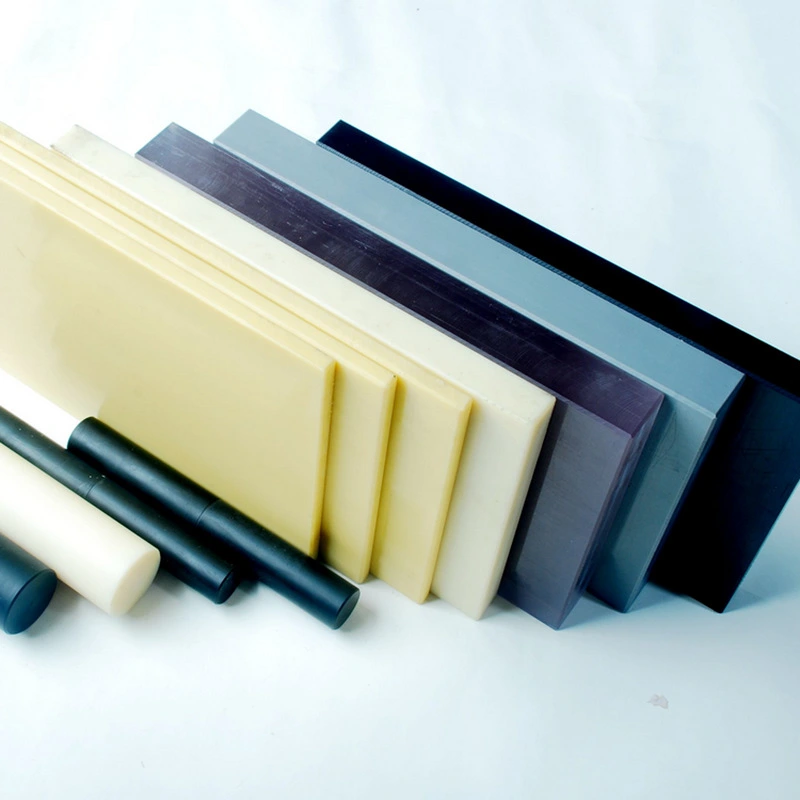

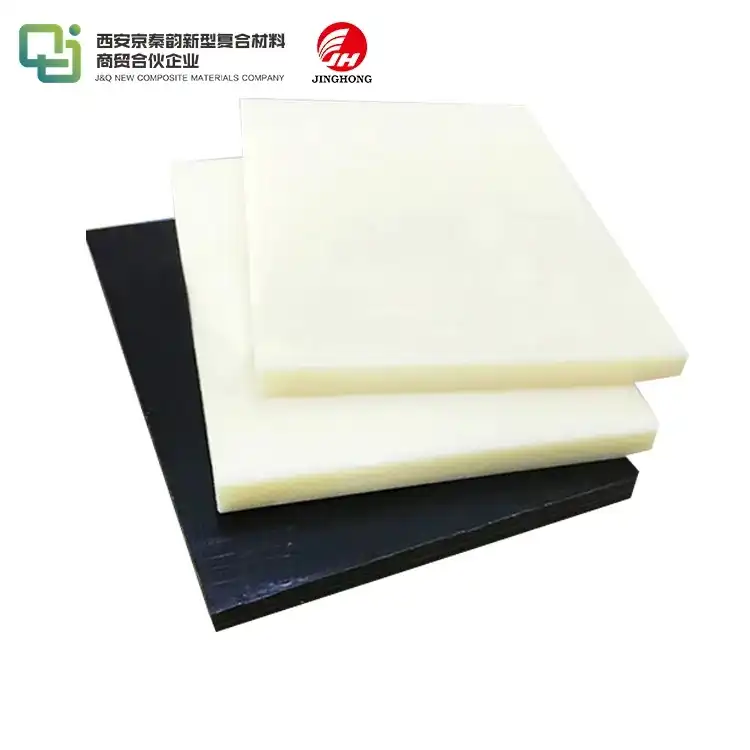

Customization Options and Specifications

The customization options for FR4 fiberglass sheets are extensive, catering to a wide array of project requirements. Thickness is a key variable, with options typically ranging from thin sheets of 0.2mm to thicker plates of 6mm or more. The choice of thickness depends on the specific application, balancing factors such as mechanical strength, weight, and thermal management.

Dimensional customization is virtually unlimited, with the ability to produce pieces ranging from small components for electronic devices to large panels for industrial applications. Complex shapes, including curves, cutouts, and holes, can be incorporated into the design to meet specific functional or aesthetic requirements.

Surface finish is another important customization option. While FR4 sheets typically have a smooth surface, special finishes can be applied to enhance certain properties. For instance, a textured surface might be added to improve adhesion in bonding applications, or a specialized coating could be applied to increase chemical resistance or provide additional insulation.

Maximizing the Benefits of Custom-Cut FR4 Fiberglass Sheets

Design Considerations for Optimal Performance

To fully leverage the advantages of custom-cut FR4 fiberglass sheets, careful consideration must be given to the design phase. Engineers and designers should take into account the unique properties of FR4 when conceptualizing their projects. The material's anisotropic nature, meaning its properties can vary depending on the direction of the fiberglass weave, should be factored into the design to ensure optimal performance.

Thermal management is a critical aspect to consider, especially in applications where heat dissipation is crucial. While FR4 is an excellent electrical insulator, it is not an ideal thermal conductor. Designers may need to incorporate features such as copper planes or thermal vias to enhance heat dissipation in high-power applications.

The orientation of cuts relative to the fiberglass weave can impact the mechanical properties of the final product. Aligning cuts with the weave direction can maximize strength in certain applications, while diagonal cuts might be preferred in others for balanced properties. Collaborating closely with the custom-cutting provider during the design phase can help optimize these aspects for each specific application.

Cost-Effective Strategies for Ordering Custom-Cut Sheets

While custom-cut FR4 fiberglass sheets offer numerous benefits, implementing cost-effective strategies can further enhance their value. One approach is to optimize material utilization through careful nesting of parts during the cutting process. By arranging multiple pieces to be cut from a single sheet in the most efficient manner, material waste can be significantly reduced, leading to cost savings.

Considering the volume of your order is another important factor. Many custom-cutting services offer volume discounts, so consolidating orders or planning for future needs can result in more favorable pricing. Additionally, discussing your long-term requirements with the supplier may lead to advantageous pricing structures or inventory management solutions.

Exploring different cutting technologies and their associated costs is also worthwhile. While some cutting methods may offer higher precision, they might not always be necessary for every application. Balancing the required level of precision with cost-effectiveness can lead to significant savings without compromising quality.

Maintenance and Handling of Custom-Cut FR4 Sheets

Proper maintenance and handling of custom-cut FR4 fiberglass sheets are essential to preserve their properties and ensure longevity. Storage conditions play a crucial role in maintaining the integrity of the material. FR4 sheets should be stored in a clean, dry environment, away from direct sunlight and extreme temperatures. Humidity control is particularly important, as excessive moisture can affect the electrical properties of the material.

When handling custom-cut FR4 sheets, care should be taken to avoid scratching or damaging the surface. Clean gloves should be worn to prevent contamination from oils or other substances that could impact subsequent processing or application. For larger sheets, proper support should be provided to prevent warping or stress on the material.

In applications where the FR4 sheets are exposed to harsh environments or chemicals, regular inspection and cleaning may be necessary. Mild detergents and water are typically sufficient for cleaning, but specific cleaning protocols should be developed based on the particular application and environment.

Conclusion

Custom-cut FR4 fiberglass sheets represent a pinnacle of precision and versatility in materials engineering. By tailoring these sheets to exact specifications, industries across the spectrum can optimize their processes, enhance product performance, and drive innovation. The combination of FR4's exceptional properties with the flexibility of custom cutting opens up a world of possibilities for designers and engineers. As technology continues to advance, the demand for precisely crafted materials like custom-cut FR4 sheets is only set to increase. Embracing this customized approach not only meets current needs but also paves the way for future developments in electronics, aerospace, and beyond.

Contact Us

Ready to elevate your projects with custom-cut FR4 fiberglass sheets? Our team of experts is here to help you bring your designs to life with unparalleled precision and quality. Contact us today at info@jhd-material.com to discuss your specific requirements and discover how our custom-cutting services can benefit your next project.

References

1. Johnson, R. (2022). Advanced Materials in Electronics: The Role of FR4 Fiberglass. Journal of Electronic Materials.

2. Smith, A. et al. (2021). Precision Cutting Techniques for Composite Materials. International Journal of Manufacturing Technologies.

3. Lee, S. (2023). Custom-Cut FR4 Sheets: Optimizing Performance in Aerospace Applications. Aerospace Engineering Review.

4. Brown, T. (2022). Cost-Effective Strategies in Custom Material Procurement. Industrial Economics Quarterly.

5. Garcia, M. (2023). Maintaining the Integrity of FR4 Fiberglass Sheets in Industrial Applications. Materials Maintenance Journal.

6. Wilson, D. (2021). The Future of Custom Materials in Electronics Manufacturing. Electronics Industry Trends Report.