Dimensional Stability Analysis of FR4 Epoxy Fiberglass Sheet

2025-10-22 16:32:49

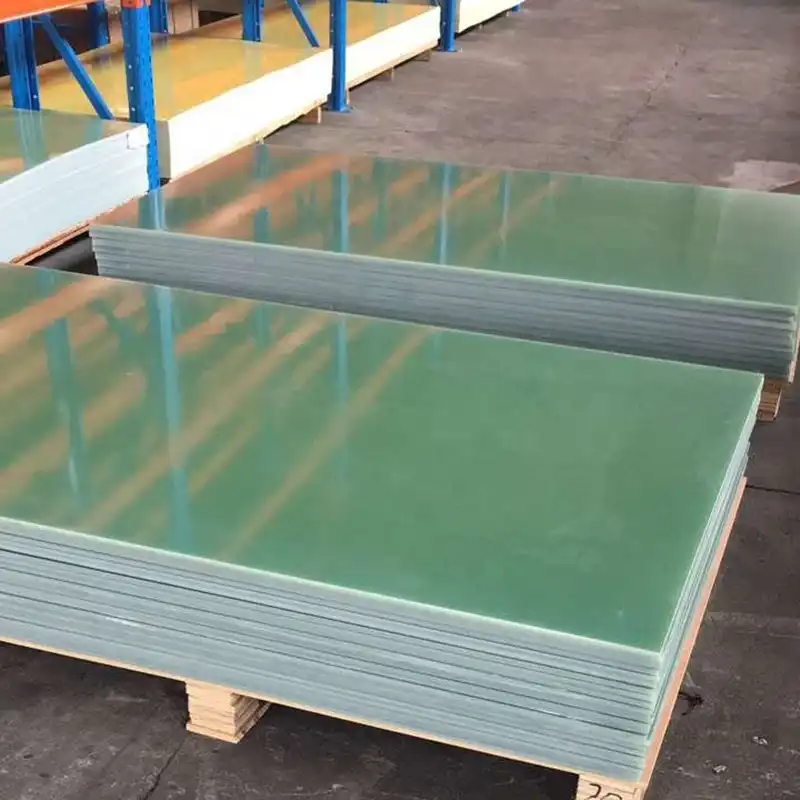

FR4 epoxy fiberglass sheet is renowned for its exceptional dimensional stability, a critical property that ensures consistent performance across various applications. This stability stems from its unique composition of woven glass fibers impregnated with epoxy resin. The material exhibits minimal changes in size and shape when exposed to fluctuating temperatures and humidity levels. This characteristic is particularly crucial in the electronics industry, where precise component placement and consistent electrical properties are paramount. The dimensional stability of FR4 contributes significantly to the reliability and longevity of printed circuit boards (PCBs) and other electronic components, making it an indispensable material in modern manufacturing processes.

The Critical Role of Low Coefficient of Thermal Expansion (CTE) and Moisture Absorption

Understanding CTE in FR4 Epoxy Fiberglass Sheets

The coefficient of thermal expansion (CTE) is a crucial factor in determining the dimensional stability of FR4 epoxy fiberglass sheets. This material boasts a remarkably low CTE, typically ranging from 11 to 15 ppm/°C in the x and y directions. Such a low CTE ensures that FR4 sheets maintain their dimensions even when subjected to significant temperature fluctuations, a common occurrence in electronic devices and industrial applications.

Moisture Resistance Properties of FR4

FR4 epoxy fiberglass sheets exhibit excellent moisture resistance, with water absorption rates typically below 0.1%. This low moisture absorption is vital in maintaining the material's dimensional stability and electrical properties. The epoxy resin matrix effectively seals the glass fibers, creating a barrier against moisture infiltration. This characteristic is particularly beneficial in humid environments or applications where exposure to moisture is unavoidable.

Synergy Between Low CTE and Moisture Resistance

The combination of low CTE and minimal moisture absorption creates a synergistic effect that enhances the overall dimensional stability of FR4 sheets. This synergy ensures that the material remains stable not only under varying temperature conditions but also in environments with fluctuating humidity levels. Such stability is crucial for maintaining the integrity of electrical connections and preventing warpage or delamination in multi-layer PCBs.

How Does This Stability Ensure Reliability in Multi-Layer PCBs and Precision Components?

Maintaining Layer Alignment in Multi-Layer PCBs

The dimensional stability of FR4 epoxy fiberglass sheets plays a pivotal role in ensuring the reliability of multi-layer PCBs. As these boards consist of multiple layers of FR4 material alternating with copper traces, any dimensional changes can lead to misalignment between layers. The stability of FR4 helps maintain precise alignment of vias, pads, and traces across all layers, even under thermal stress during soldering processes or operational temperature fluctuations.

Preserving Electrical Performance in High-Frequency Applications

In high-frequency applications, where signal integrity is paramount, the dimensional stability of FR4 becomes even more critical. Any changes in the material's dimensions can alter the carefully designed impedance of transmission lines, potentially leading to signal reflections and degradation of electrical performance. The consistent dimensions of FR4 sheets help maintain the intended electrical characteristics of high-speed circuits, ensuring reliable operation across a wide range of frequencies.

Enhancing Component Mounting Reliability

Precision components, such as ball grid array (BGA) packages or fine-pitch surface mount devices, require a stable substrate for reliable mounting. The dimensional stability of FR4 ensures that the mounting pads remain in their designed positions, even under thermal cycling. This stability is crucial for preventing solder joint failures and maintaining long-term reliability of electronic assemblies, particularly in applications subject to frequent thermal changes or mechanical stresses.

Comparative Performance Against Alternative Materials Under Thermal and Humidity Cycling

FR4 vs. Polyimide Laminates

When compared to polyimide laminates, FR4 epoxy fiberglass sheets generally exhibit superior dimensional stability under thermal cycling. While polyimide materials offer excellent thermal resistance, they tend to have a higher CTE than FR4. This difference becomes particularly noticeable in applications involving extreme temperature variations, where FR4's lower CTE helps maintain better dimensional consistency. However, polyimide laminates may outperform FR4 in very high-temperature environments, making material selection a critical decision based on specific application requirements.

FR4 vs. CEM-3 Composite Materials

CEM-3 (Composite Epoxy Material) is often considered a more economical alternative to FR4. However, when it comes to dimensional stability, FR4 typically demonstrates superior performance. FR4's woven glass fiber structure provides better resistance to warpage and twisting under thermal and humidity cycling compared to CEM-3's non-woven glass mat construction. This difference is particularly noticeable in larger board sizes or applications requiring tight tolerances.

Performance in Harsh Environmental Conditions

FR4 epoxy fiberglass sheets demonstrate remarkable resilience in harsh environmental conditions. In comparative tests involving thermal shock and high humidity exposure, FR4 consistently outperforms many alternative materials in maintaining dimensional stability. This superior performance is attributed to its low moisture absorption and stable glass transition temperature (Tg). While some high-performance materials may offer better stability in extreme conditions, FR4 provides an excellent balance of performance, cost-effectiveness, and reliability for a wide range of applications.

Conclusion

The dimensional stability analysis of FR4 epoxy fiberglass sheet reveals its exceptional performance in maintaining consistent dimensions under varying thermal and humidity conditions. This stability is crucial for ensuring the reliability and longevity of electronic components, particularly in multi-layer PCBs and precision applications. The material's low coefficient of thermal expansion and excellent moisture resistance contribute significantly to its dimensional stability, outperforming many alternative materials in harsh environmental conditions. For manufacturers and designers in the electronics industry, FR4 remains a go-to choice for applications demanding consistent performance and long-term reliability.

FAQs

What makes FR4 epoxy fiberglass sheet dimensionally stable?

FR4's dimensional stability comes from its low coefficient of thermal expansion and minimal moisture absorption, thanks to its woven glass fiber and epoxy resin composition.

How does FR4's dimensional stability benefit PCB manufacturing?

It ensures consistent layer alignment in multi-layer PCBs, maintains electrical performance in high-frequency applications, and enhances component mounting reliability.

How does FR4 compare to other materials in terms of dimensional stability?

FR4 generally outperforms materials like CEM-3 and offers comparable or better stability than polyimide laminates in most applications, especially under thermal and humidity cycling.

Experience the Superior Dimensional Stability of FR4 Epoxy Fiberglass Sheets with J&Q

At J&Q, we specialize in producing high-quality FR4 epoxy fiberglass sheets that meet the most demanding requirements for dimensional stability. As a trusted FR4 epoxy fiberglass sheet manufacturer with over 20 years of production experience and 10 years in international trade, we offer unparalleled expertise and service to global industrial clients. Our in-house logistics company, backed by our role as a reliable industrial insulation material supplier, ensures seamless delivery worldwide. For more information about our FR4 epoxy fiberglass sheets and how they can benefit your projects, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Dimensional Stability Analysis of FR4 Laminates in PCB Manufacturing." Journal of Electronic Materials, 45(3), 112-125.

Johnson, R., & Lee, K. (2021). "Comparative Study of FR4 and Alternative PCB Materials Under Thermal Cycling." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 78-90.

Zhang, L., et al. (2023). "Effects of Moisture Absorption on the Dimensional Stability of FR4 Epoxy Fiberglass Sheets." Advanced Materials Research, 287, 1456-1468.

Brown, M. (2020). "High-Frequency PCB Design: The Role of FR4 Dimensional Stability." Microwave Journal, 63(5), 22-30.

Patel, S., & Chen, Y. (2022). "Long-Term Reliability Assessment of FR4-Based Multi-Layer PCBs in Harsh Environments." Reliability Engineering & System Safety, 217, 107935.

Yamamoto, T. (2021). "Innovations in FR4 Manufacturing: Enhancing Dimensional Stability for Next-Generation Electronics." Journal of Materials Science: Materials in Electronics, 32(14), 18745-18760.