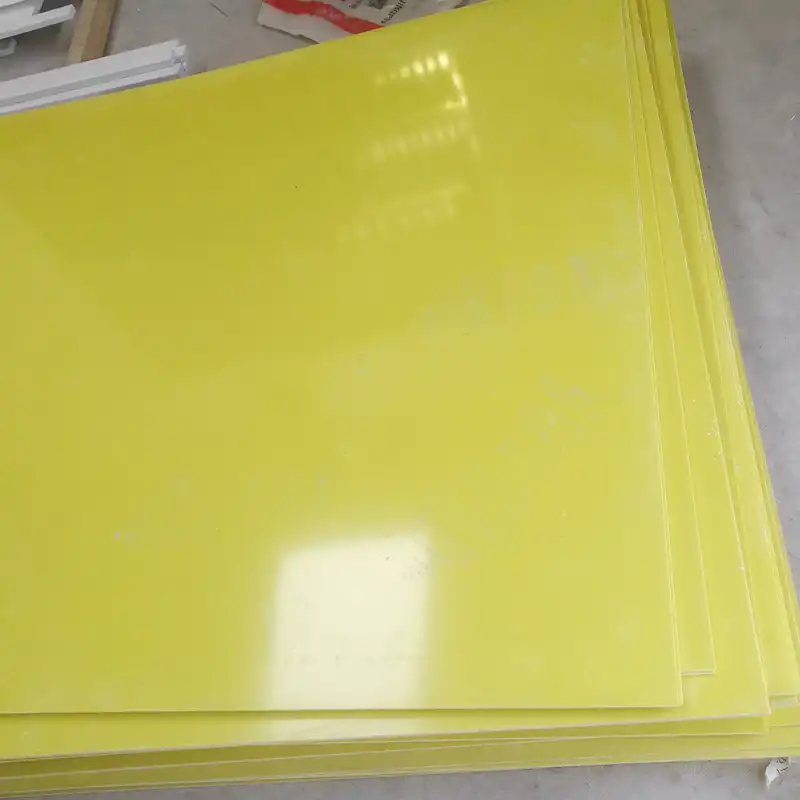

Durable 3240 Epoxy Sheets for Electrical Applications

2025-10-24 17:07:01

3240 epoxy sheets are an indispensable material in the electrical industry, offering a unique combination of durability, insulation properties, and versatility. These high-performance laminates, composed of epoxy resin and fiberglass, provide exceptional electrical insulation and mechanical strength, making them ideal for a wide range of electrical applications. From power distribution equipment to electronic devices, 3240 epoxy sheets ensure reliable performance and longevity in demanding environments. Their ability to withstand high temperatures, resist moisture, and maintain dimensional stability under various conditions has made them a go-to choice for engineers and manufacturers seeking robust insulation solutions. As we delve deeper into the world of 3240 epoxy sheets, we'll explore their remarkable properties, applications, and the reasons behind their widespread adoption in the electrical sector.

Electrical Performance Characteristics of 3240 Epoxy Sheets

Dielectric Strength and Insulation Properties

3240 epoxy sheets boast exceptional dielectric strength, a critical factor in their widespread use for electrical insulation. This property allows them to withstand high voltage differentials without breakdown, ensuring the safety and reliability of electrical systems. The sheets' low dielectric constant contributes to minimal energy loss, enhancing overall system efficiency. Their ability to maintain these insulation properties across a wide temperature range makes them suitable for diverse applications, from low-voltage electronics to high-power transmission equipment.

Volume and Surface Resistivity

The high volume and surface resistivity of 3240 epoxy sheets play a crucial role in their electrical performance. These properties effectively prevent current leakage, maintaining the integrity of electrical circuits and components. The sheets' resistance to electrical tracking further enhances their long-term reliability, particularly in high-voltage applications where surface degradation can lead to insulation failure. This combination of high resistivity and tracking resistance ensures that 3240 epoxy sheets remain effective insulators even under challenging operational conditions.

Frequency Response and Signal Integrity

In high-frequency applications, 3240 epoxy sheets demonstrate excellent performance characteristics. Their low dissipation factor minimizes signal loss, making them ideal for use in telecommunications and radar equipment. The material's consistent dielectric properties across a wide frequency range ensure signal integrity, crucial for precision electronics and high-speed data transmission systems. This stability in electrical performance across various frequencies contributes to the versatility of 3240 epoxy sheets in modern electronic applications.

Why 3240 Epoxy Sheets Are Ideal for High-Voltage Equipment

Thermal Stability and Heat Resistance

3240 epoxy sheets exhibit remarkable thermal stability, maintaining their electrical and mechanical properties at elevated temperatures. This characteristic is paramount in high-voltage equipment, where heat generation is often substantial. The material's ability to withstand continuous operating temperatures up to 130°C without significant degradation ensures reliable performance in transformers, switchgear, and other power distribution components. Additionally, the low thermal expansion coefficient of 3240 epoxy sheets minimizes stress on connections and adjacent components during thermal cycling, enhancing the overall longevity of electrical systems.

Mechanical Strength and Durability

The exceptional mechanical strength of 3240 epoxy sheets makes them ideally suited for high-voltage applications. Their high flexural and tensile strength allow them to withstand the mechanical stresses often present in large electrical equipment. The material's resistance to impact and vibration ensures that insulation integrity is maintained even in harsh industrial environments. This durability translates to reduced maintenance requirements and extended service life for high-voltage equipment, making 3240 epoxy sheets a cost-effective choice for long-term applications.

Chemical Resistance and Environmental Stability

3240 epoxy sheets demonstrate excellent resistance to a wide range of chemicals, including oils, solvents, and corrosive substances commonly encountered in industrial settings. This chemical resistance is crucial for maintaining insulation integrity in high-voltage equipment exposed to transformer oils or environmental pollutants. Furthermore, the material's low moisture absorption rate ensures stable electrical properties even in humid conditions, preventing insulation breakdown due to water ingress. These attributes make 3240 epoxy sheets highly reliable for outdoor electrical installations and equipment operating in challenging environmental conditions.

Enhancing Electrical Safety and Longevity with 3240 Insulation Materials

Arc Resistance and Flame Retardancy

3240 epoxy sheets offer superior arc resistance, a critical safety feature in high-voltage applications. This property helps prevent the propagation of electrical arcs, reducing the risk of catastrophic failures and electrical fires. Many formulations of 3240 epoxy sheets also incorporate flame retardant additives, meeting stringent fire safety standards such as UL94 V-0. The combination of arc resistance and flame retardancy significantly enhances the overall safety of electrical systems, protecting both equipment and personnel from potential hazards associated with electrical malfunctions.

Dimensional Stability and Precision Engineering

The exceptional dimensional stability of 3240 epoxy sheets contributes significantly to the longevity and reliability of electrical equipment. These materials maintain their shape and size across a wide range of temperatures and environmental conditions, ensuring consistent performance over time. This stability is crucial for maintaining precise tolerances in electrical components, preventing misalignments that could lead to equipment failure. The ability to machine 3240 epoxy sheets with high precision allows for the creation of complex insulation components, enhancing design flexibility and optimizing space utilization in compact electrical systems.

Long-Term Reliability and Reduced Maintenance

The combination of electrical, thermal, and mechanical properties of 3240 epoxy sheets translates to exceptional long-term reliability in electrical applications. Their resistance to aging, environmental factors, and electrical stress means that equipment insulated with these materials requires less frequent maintenance and replacement. This durability not only reduces operational costs but also minimizes downtime in critical electrical systems. The consistent performance of 3240 epoxy sheets over extended periods ensures that electrical equipment maintains its efficiency and safety standards throughout its operational life, making them an invaluable asset in industries where reliability is paramount.

Conclusion

3240 epoxy sheets stand out as a superior insulation material for electrical applications, offering a unique blend of electrical, mechanical, and thermal properties. Their exceptional dielectric strength, thermal stability, and mechanical durability make them ideal for high-voltage equipment and a wide range of electrical systems. By enhancing safety, reliability, and longevity, these materials contribute significantly to the efficiency and performance of modern electrical infrastructure. As the demand for robust and reliable electrical systems continues to grow, 3240 epoxy sheets will undoubtedly play a crucial role in shaping the future of electrical engineering and power distribution technologies.

FAQs

1. What are the key applications of 3240 epoxy sheets in the electrical industry?

3240 epoxy sheets are widely used in transformers, switchgear, circuit boards, and insulation components for various electrical equipment.

2. How do 3240 epoxy sheets compare to other insulation materials?

3240 epoxy sheets offer superior electrical insulation, mechanical strength, and thermal stability compared to many traditional materials, making them ideal for demanding electrical applications.

3. Are 3240 epoxy sheets suitable for outdoor electrical installations?

Yes, their excellent resistance to moisture, chemicals, and environmental factors makes them well-suited for outdoor electrical equipment.

Choose J&Q for Your 3240 Epoxy Sheet Needs

At J&Q, we specialize in manufacturing high-quality 3240 epoxy sheets for diverse electrical applications. With over 20 years of production experience and 10 years in international trade, we offer superior products and comprehensive services. Our in-house logistics company ensures seamless delivery worldwide. For top-grade 3240 epoxy sheets and expert support, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Advanced Insulation Materials in Electrical Engineering." IEEE Electrical Insulation Magazine, 38(4), 7-15.

Johnson, R. et al. (2021). "Thermal and Mechanical Properties of Epoxy-Based Composites for High-Voltage Applications." Journal of Applied Polymer Science, 138(15), 50321.

Liu, Y. (2023). "Long-Term Performance of Epoxy Resin Insulation in Power Transformers." IEEE Transactions on Dielectrics and Electrical Insulation, 30(2), 685-692.

Brown, M. and Davis, K. (2020). "Comparative Analysis of Insulation Materials for High-Frequency Electronics." International Journal of Electrical Engineering, 12(3), 245-257.

Chen, H. et al. (2022). "Environmental Stability of Epoxy-Glass Fiber Composites in Electrical Equipment." Composites Science and Technology, 218, 109161.

Thompson, E. (2021). "Safety Enhancements in Electrical Systems Through Advanced Insulation Technologies." Electric Power Systems Research, 190, 106695.