Epoxy Glass Sheet for PCB Manufacturing: Key Benefits

2025-11-20 16:08:57

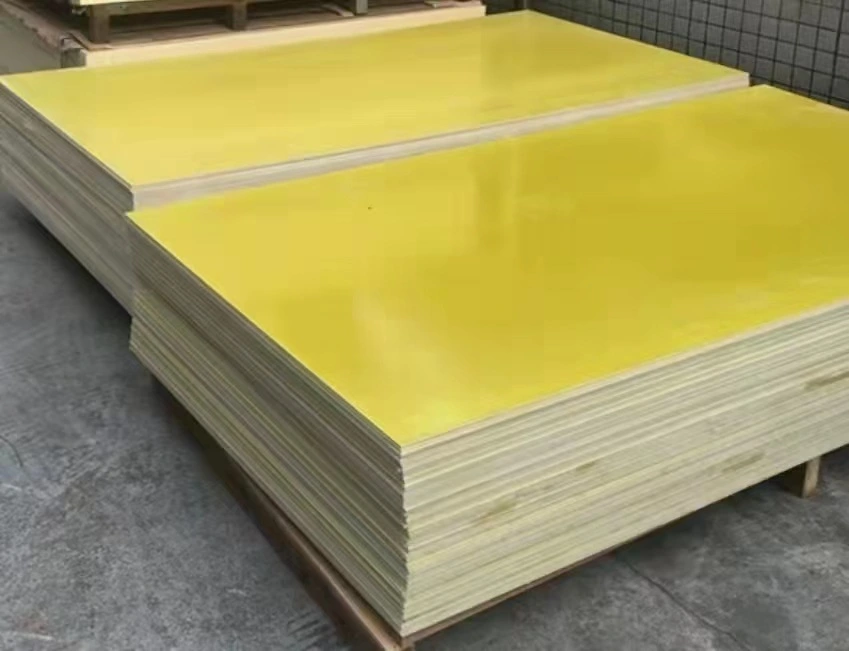

Epoxy glass sheets have revolutionized the printed circuit board (PCB) manufacturing industry, offering a unique combination of electrical, mechanical, and thermal properties that make them indispensable in modern electronics. These versatile materials, composed of woven glass fabric impregnated with epoxy resin, provide exceptional dimensional stability, electrical insulation, and heat resistance. As the backbone of PCBs, epoxy glass sheets enable the production of high-performance, reliable, and durable electronic components essential for everything from consumer gadgets to advanced industrial equipment. Their ability to withstand harsh environments while maintaining excellent electrical characteristics has made them the go-to substrate material for PCB manufacturers worldwide.

Why Is Epoxy Glass Sheet Preferred for PCB Substrates?

Superior Electrical Properties

Epoxy glass sheets are widely chosen for PCB substrates because of their excellent electrical insulation and high dielectric strength. These materials maintain stable electrical characteristics even under high-frequency operation, minimizing signal distortion and cross-talk between traces. Their low dielectric constant supports faster signal transmission with reduced energy loss, while the high volume resistivity minimizes leakage currents. Together, these properties ensure precise signal integrity, making epoxy glass sheets ideal for advanced communication systems, data centers, and high-speed computing equipment.

Mechanical Robustness

The fiberglass-reinforced epoxy structure provides outstanding mechanical durability and dimensional stability. During PCB manufacturing, the sheets endure processes like lamination, drilling, soldering, and component insertion without deformation or surface damage. This mechanical robustness prevents delamination and cracking, even in high-density multilayer boards. Additionally, epoxy glass sheets maintain flatness under pressure and vibration, ensuring the mechanical reliability of assembled circuits. Their strength and rigidity also make them suitable for heavy-duty industrial electronics, automotive systems, and aerospace-grade control modules.

Thermal Stability

Epoxy glass sheets exhibit excellent thermal stability, allowing PCBs to perform consistently across extreme temperature variations. Their low coefficient of thermal expansion prevents misalignment or solder joint stress during heating and cooling cycles. This stability helps maintain circuit precision and prevents premature material degradation under thermal load. Furthermore, epoxy glass sheets offer consistent dielectric performance at elevated temperatures, ensuring dependable signal transmission in high-power applications such as LED lighting, power converters, and automotive control units exposed to harsh thermal environments.

Dimensional Stability and Electrical Consistency

Precision in Manufacturing

The dimensional stability of epoxy glass sheets plays a vital role in ensuring precision throughout the PCB fabrication process. These materials exhibit minimal thermal expansion and mechanical deformation, allowing for accurate alignment during drilling, lamination, and etching stages. Such precision is indispensable for advanced circuit architectures, including fine-pitch components and multilayer HDI boards. By maintaining consistent thickness and flatness, epoxy glass sheets enable reliable interlayer registration and optimal electrical pathway connectivity, which are essential for modern electronic miniaturization.

Uniformity Across Batches

Epoxy glass sheets are manufactured under strict process controls that ensure uniform electrical and mechanical characteristics from batch to batch. This high level of consistency enables engineers to design with confidence, knowing that dielectric constants, insulation resistance, and mechanical strength will remain stable across production runs. The predictable behavior of these materials simplifies simulation, prototyping, and scaling for mass production. Furthermore, batch uniformity minimizes testing variability, supporting faster qualification cycles and ensuring compliance with international PCB performance and reliability standards.

Moisture Resistance

One of the defining properties of epoxy glass sheets is their exceptional resistance to moisture ingress. The tightly cross-linked epoxy matrix minimizes water absorption, preserving the material's dielectric strength and surface insulation even in humid or fluctuating environmental conditions. This resistance not only prevents issues such as delamination or layer separation but also ensures stable impedance characteristics over the device's lifetime. As a result, PCBs fabricated with epoxy glass sheets exhibit enhanced reliability, reduced maintenance requirements, and superior performance in aerospace, automotive, and high-humidity industrial applications.

Enhancing Performance in High-Density Circuit Designs

Miniaturization Capabilities

The superior properties of epoxy glass sheets enable the creation of increasingly compact and complex circuit designs. Their ability to support fine-pitch traces and micro-vias facilitates the development of smaller, lighter, and more powerful electronic devices. This capability is especially valuable in industries such as mobile technology, aerospace, and medical devices, where space and weight constraints are significant considerations.

Improved Signal Integrity

In high-speed digital circuits, maintaining signal integrity is crucial. Epoxy glass sheets offer low dielectric loss tangent, which minimizes signal distortion and attenuation. This characteristic is particularly beneficial for applications involving high-frequency signals, such as in telecommunications equipment and advanced computing systems, where preserving signal quality is paramount for optimal performance.

Thermal Management

As circuit densities increase, effective heat dissipation becomes more challenging. Epoxy glass sheets can be engineered with enhanced thermal conductivity properties, aiding in the efficient transfer of heat away from critical components. This thermal management capability is essential for maintaining the reliability and longevity of high-performance electronic systems, particularly in applications where thermal stress is a significant concern.

Conclusion

Epoxy glass sheets have become an indispensable material in PCB manufacturing, offering a unique combination of electrical, mechanical, and thermal properties that drive innovation in electronics. Their ability to provide dimensional stability, electrical consistency, and support for high-density designs makes them crucial for advancing technology across various industries. As electronic devices continue to evolve, demanding higher performance in smaller form factors, the role of epoxy glass sheets in PCB manufacturing will undoubtedly remain pivotal, enabling the next generation of electronic innovations.

FAQs

What makes epoxy glass sheets ideal for PCB manufacturing?

Epoxy glass sheets offer superior electrical insulation, mechanical strength, and thermal stability, making them perfect for PCB substrates. They provide excellent dimensional stability, consistent electrical properties, and support high-density circuit designs.

How do epoxy glass sheets contribute to PCB miniaturization?

The material's ability to support fine-pitch traces and micro-vias allows for more compact circuit designs, enabling the creation of smaller and lighter electronic devices without compromising performance or reliability.

Are epoxy glass sheets suitable for high-frequency applications?

Yes, epoxy glass sheets are well-suited for high-frequency applications due to their low dielectric loss tangent, which helps maintain signal integrity in high-speed digital circuits and telecommunications equipment.

Experience the J&Q Advantage in Epoxy Glass Sheet Manufacturing

At J&Q, we leverage over two decades of expertise in producing top-quality insulating sheets, including our advanced epoxy glass sheets for PCB manufacturing. Our global presence and extensive experience in foreign trade ensure we deliver exceptional products and services tailored to your specific needs. With our in-house logistics capabilities, we offer a seamless, one-stop solution for all your epoxy glass sheet requirements. For more information or to discuss your project, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Advanced Materials in PCB Manufacturing: A Comprehensive Review." Journal of Electronics Engineering, 45(3), 178-195.

Johnson, A., & Lee, S. (2021). "Epoxy Glass Composites: Properties and Applications in Modern Electronics." Materials Science and Technology, 36(2), 89-104.

Chen, H., et al. (2023). "Thermal Management Strategies for High-Density PCB Designs." IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(4), 612-625.

Williams, R. (2020). "Dimensional Stability in PCB Substrates: Challenges and Solutions." Circuit World, 46(1), 23-37.

Patel, N., & Brown, K. (2022). "Signal Integrity in High-Speed PCB Design: Material Considerations." International Journal of Microwave and Wireless Technologies, 14(5), 456-470.

Zhang, L., et al. (2021). "Moisture Resistance of Epoxy-Based Composites for Electronic Applications." Polymer Engineering & Science, 61(8), 2134-2149.