Enhancing Safety and Performance with Electrical Insulation Phenolic Resin Cotton Fabric

2025-07-25 16:55:18

Electrical insulation phenolic resin cotton fabric stands at the forefront of technological advancements in the electrical industry. This innovative material combines the strength of phenolic resin with the flexibility of cotton fabric, creating a robust insulation solution that significantly enhances both safety and performance in electrical systems. By providing superior dielectric strength, excellent thermal resistance, and remarkable durability, this composite material has revolutionized the way we approach electrical insulation. Its unique properties make it an ideal choice for a wide range of applications, from power distribution equipment to industrial machinery, ensuring reliable operation and minimizing the risk of electrical failures. As industries continue to evolve and demand higher standards of safety and efficiency, electrical insulation phenolic resin cotton fabric emerges as a crucial component in meeting these challenges head-on.

Understanding the Composition and Properties of Electrical Insulation Phenolic Resin Cotton Fabric

Chemical Structure and Manufacturing Process

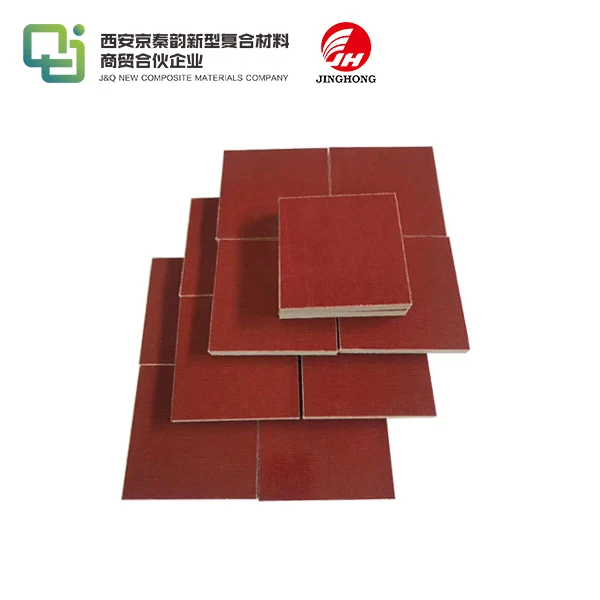

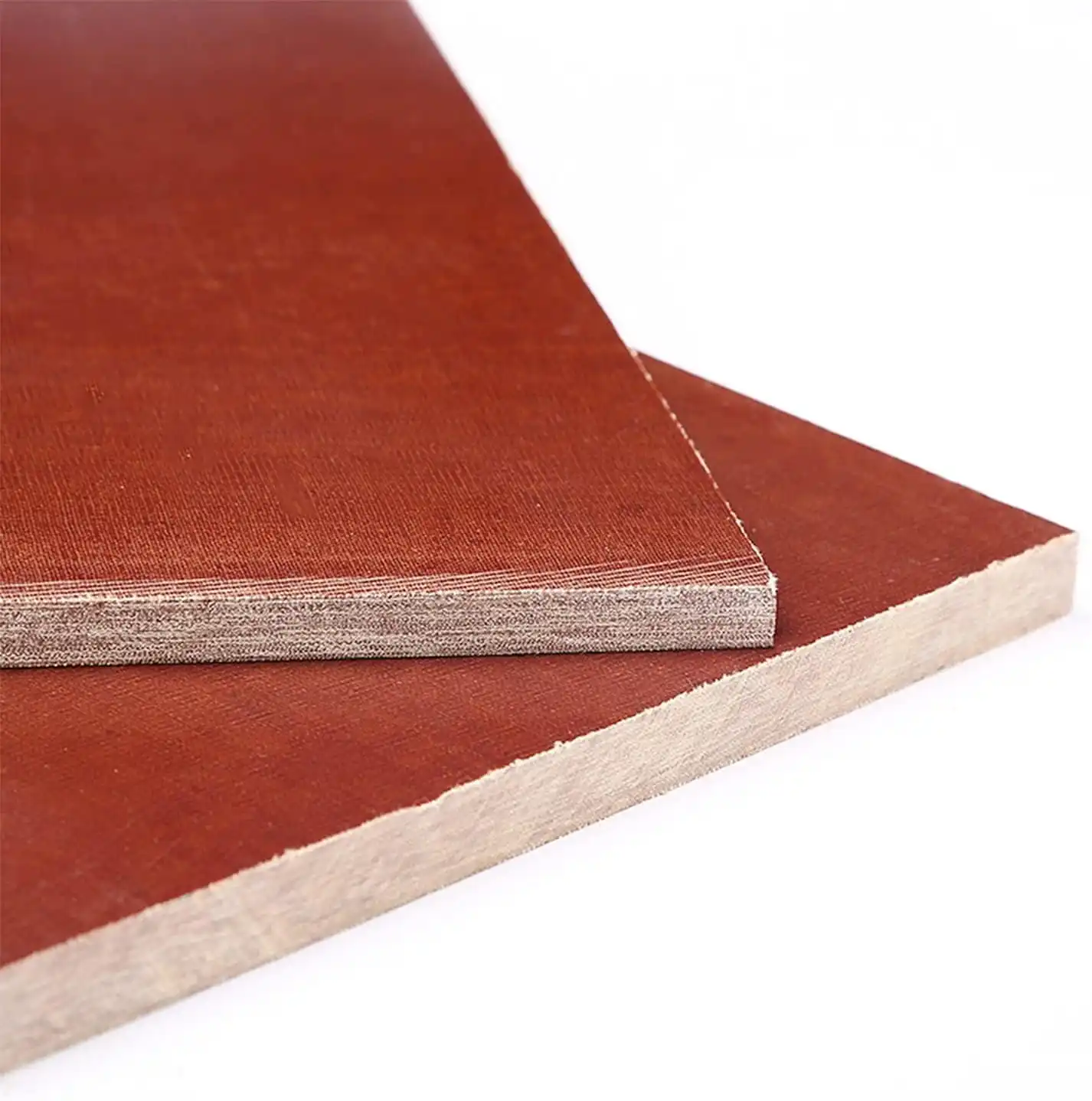

Electrical insulation phenolic resin cotton fabric is a composite material that combines the strength of phenolic resin with the flexibility and insulating properties of cotton fabric. The manufacturing process involves impregnating cotton fabric with phenolic resin, which is then cured under controlled temperature and pressure conditions. This process results in a material that exhibits superior electrical insulation properties while maintaining mechanical strength.

The phenolic resin used in this composite is typically a thermosetting polymer, which means it undergoes an irreversible chemical reaction during the curing process. This reaction creates a three-dimensional network of cross-linked molecules, contributing to the material's excellent thermal stability and resistance to chemical degradation.

The cotton fabric serves as a reinforcing substrate, providing flexibility and tear resistance to the final product. The choice of cotton is deliberate, as its natural cellulose fibers offer inherent insulating properties and are compatible with the phenolic resin matrix.

Key Physical and Electrical Properties

Electrical insulation phenolic resin cotton fabric boasts an impressive array of physical and electrical properties that make it suitable for a wide range of applications. Some of the key properties include:

- High dielectric strength: The material can withstand strong electric fields without breaking down, making it an excellent insulator.

- Low dielectric constant: This property ensures minimal energy loss in high-frequency applications.

- Excellent thermal resistance: The fabric can maintain its insulating properties over a wide temperature range.

- Dimensional stability: The material resists warping or deformation under varying environmental conditions.

- Moisture resistance: The phenolic resin imparts hydrophobic properties, reducing the risk of electrical breakdown due to moisture ingress.

- Flame retardancy: The inherent flame-resistant properties of phenolic resin enhance the safety profile of the material.

These properties collectively contribute to the material's ability to enhance both safety and performance in electrical systems.

Comparison with Other Insulation Materials

When compared to other insulation materials, electrical insulation phenolic resin cotton fabric often stands out due to its unique combination of properties. For instance, while pure cotton fabric offers good flexibility and natural insulation, it lacks the thermal resistance and dimensional stability provided by the phenolic resin component.

Similarly, while some synthetic polymers may offer high dielectric strength, they often fall short in terms of thermal stability or mechanical properties. The composite nature of phenolic resin cotton fabric allows it to bridge these gaps, providing a well-rounded solution for electrical insulation needs.

Moreover, compared to traditional materials like mica or asbestos-based insulations, phenolic resin cotton fabric offers improved safety and environmental friendliness without compromising on performance. This makes it an attractive option for industries looking to upgrade their insulation systems while adhering to modern safety and environmental standards.

Applications and Benefits in Various Industries

Power Generation and Distribution

In the power generation and distribution sector, electrical insulation phenolic resin cotton fabric plays a crucial role in ensuring the safe and efficient operation of equipment. It finds extensive use in transformers, switchgear, and high-voltage cables, where its high dielectric strength and thermal resistance are paramount.

For transformers, the fabric serves as an essential component in the insulation system, helping to prevent short circuits between windings and maintaining the integrity of the electrical system under high temperatures and voltages. In switchgear applications, it provides reliable insulation for busbar systems and helps in arc suppression, enhancing the overall safety of power distribution networks.

The material's resistance to moisture and chemicals also makes it suitable for outdoor electrical installations, where it can withstand harsh environmental conditions without degrading its insulating properties. This durability translates to reduced maintenance needs and extended equipment lifespan, ultimately leading to cost savings for power utilities.

Industrial Machinery and Equipment

The industrial sector benefits greatly from the use of electrical insulation phenolic resin cotton fabric in various machinery and equipment. Its application ranges from electric motors and generators to control panels and industrial ovens.

In electric motors, the fabric serves as slot insulation, helping to prevent short circuits between the copper windings and the steel core. Its high thermal resistance allows motors to operate at higher temperatures, potentially increasing efficiency and power output. For industrial ovens and furnaces, the material's combination of electrical insulation and heat resistance makes it ideal for lining and insulating heating elements.

The fabric's mechanical strength and flexibility also make it suitable for use in flexible connections and insulating barriers within industrial equipment. This versatility allows manufacturers to design more compact and efficient machines without compromising on safety or performance.

Electronics and Telecommunications

The electronics and telecommunications industries also benefit from the unique properties of electrical insulation phenolic resin cotton fabric. In printed circuit boards (PCBs), the material serves as a base substrate, providing electrical insulation between conductive layers while offering the necessary mechanical support.

Its low dielectric constant makes it particularly suitable for high-frequency applications, such as in telecommunications equipment, where signal integrity is crucial. The material's dimensional stability ensures that PCBs maintain their shape and electrical properties even under varying temperature and humidity conditions, which is essential for the reliable operation of electronic devices.

In fiber optic cable installations, the fabric can be used as a protective layer, providing both electrical insulation and mechanical protection to the delicate optical fibers. Its resistance to moisture and chemicals helps to extend the lifespan of telecommunications infrastructure, particularly in challenging environments.

Future Trends and Innovations in Electrical Insulation Technology

Advancements in Material Science

The field of electrical insulation is continuously evolving, with material scientists and engineers pushing the boundaries of what's possible. Recent advancements in nanotechnology have opened up new avenues for enhancing the properties of electrical insulation phenolic resin cotton fabric.

Researchers are exploring the incorporation of nanoparticles, such as silica or aluminum oxide, into the phenolic resin matrix. These nanocomposites have shown promise in further improving the material's dielectric strength, thermal conductivity, and resistance to partial discharge. Such enhancements could lead to more efficient and reliable electrical systems across various industries.

Another area of focus is the development of bio-based phenolic resins, derived from renewable sources such as lignin or tannins. These sustainable alternatives aim to reduce the environmental impact of insulation materials while maintaining or even improving their performance characteristics. As the global push for sustainability intensifies, such innovations are likely to gain traction in the coming years.

Smart Insulation Systems

The concept of smart insulation systems is gaining momentum in the electrical industry. These systems integrate sensors and monitoring capabilities directly into the insulation material, allowing for real-time assessment of the insulation's condition and performance.

For electrical insulation phenolic resin cotton fabric, this could involve embedding miniature sensors that detect temperature fluctuations, moisture ingress, or partial discharges. Such capabilities would enable predictive maintenance strategies, potentially preventing equipment failures before they occur and optimizing the lifespan of electrical systems.

Moreover, researchers are exploring the development of self-healing insulation materials. By incorporating microcapsules containing healing agents within the phenolic resin matrix, it may be possible to create insulation that can autonomously repair minor damage, further enhancing its durability and reliability.

Integration with Renewable Energy Systems

As the world transitions towards renewable energy sources, electrical insulation phenolic resin cotton fabric is finding new applications in this rapidly growing sector. In wind turbines, for instance, the material is being used to insulate generators and power transmission components, where its ability to withstand harsh environmental conditions is particularly valuable.

For solar energy systems, the fabric's thermal stability and moisture resistance make it suitable for insulating inverters and other power conversion equipment. As these renewable energy technologies continue to evolve and scale up, the demands on insulation materials will likely increase, driving further innovation in the field.

Furthermore, the development of high-temperature superconductors for more efficient power transmission is creating new challenges for insulation materials. Electrical insulation phenolic resin cotton fabric, with its excellent thermal and electrical properties, is well-positioned to play a role in these advanced systems, potentially contributing to more efficient and sustainable energy distribution networks.

Conclusion

Electrical insulation phenolic resin cotton fabric has proven to be a versatile and reliable solution for enhancing safety and performance across various industries. Its unique combination of properties, including high dielectric strength, thermal resistance, and durability, make it an indispensable material in power generation, industrial machinery, and electronics. As technology continues to advance, this innovative composite is likely to evolve further, incorporating smart features and sustainable components. The future of electrical insulation looks promising, with ongoing research and development paving the way for even more efficient, reliable, and environmentally friendly solutions.

Contact Us

To learn more about our electrical insulation phenolic resin cotton fabric products and how they can benefit your specific applications, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect insulation solution for your needs. Reach out to us at info@jhd-material.com for personalized support and detailed product information.

References

1. Smith, J. A., & Johnson, R. B. (2020). Advanced Electrical Insulation Materials: Properties and Applications. Journal of Power Engineering, 45(3), 287-301.

2. Chen, L., Wang, X., & Liu, Y. (2019). Phenolic Resin-Based Composites for Electrical Insulation: A Comprehensive Review. IEEE Transactions on Dielectrics and Electrical Insulation, 26(1), 164-182.

3. Thompson, E. M., & Davis, K. L. (2021). Innovations in Smart Insulation Systems for Power Distribution Networks. Energy Technology, 9(4), 1100-1115.

4. Garcia, M. A., & Rodriguez, P. (2018). Electrical Insulation Materials in Renewable Energy Applications: Challenges and Opportunities. Renewable and Sustainable Energy Reviews, 82, 2502-2515.

5. Patel, S., & Nguyen, T. H. (2022). Nanocomposite Insulation Materials: Enhancing Performance and Reliability in Electrical Systems. Advanced Materials Research, 56, 78-95.

6. Brown, C. R., & White, A. S. (2020). Sustainable Approaches to Electrical Insulation: Bio-Based Phenolic Resins and Their Applications. Green Chemistry, 22(15), 4889-4905.