How Are FR4 Epoxy Laminate Made?

2025-08-08 16:23:22

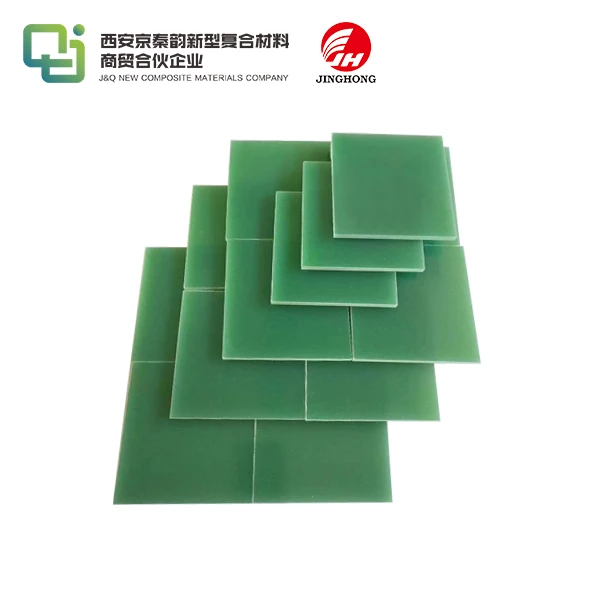

FR4 epoxy laminate is manufactured through a meticulous process involving carefully selected raw materials and precise production techniques. The fabrication begins with the selection of high-quality glass fiber cloth and epoxy resin as core components. These materials undergo impregnation, where the glass fiber is saturated with epoxy resin and additional flame-retardant additives. Multiple layers of this impregnated material are then stacked and subjected to controlled heat and pressure in a pressing process. The final step involves curing, which solidifies the resin and enhances the laminate's mechanical and thermal properties. This sophisticated manufacturing approach results in a versatile, flame-retardant material with excellent electrical insulation and mechanical strength, ideal for numerous applications in electronics and beyond.

What Raw Materials Are Used in FR4 Sheet Production?

Glass Fiber Cloth: The Backbone of FR4

Glass fiber cloth serves as the primary reinforcement material in FR4 epoxy laminate. This woven fabric, composed of interlaced glass fibers, provides the laminate with its characteristic strength and dimensional stability. The glass fibers are typically made from E-glass, a type of borosilicate glass known for its excellent electrical insulation properties and high tensile strength. The weave pattern of the cloth can vary, with common types including plain weave and satin weave, each offering different characteristics in terms of resin uptake and final laminate properties.

Epoxy Resin: The Binding Agent

Epoxy resin is the matrix material that binds the glass fibers together in FR4 laminates. This thermosetting polymer is chosen for its superior adhesion, chemical resistance, and electrical insulation properties. The epoxy used in FR4 production is typically a diglycidyl ether of bisphenol A (DGEBA) type, which offers a good balance of mechanical and electrical properties. The resin system also includes hardeners or curing agents, which initiate the cross-linking process during curing, transforming the liquid resin into a solid, infusible material.

Flame Retardants: Enhancing Fire Resistance

To achieve the flame-retardant properties that give FR4 its name, specific additives are incorporated into the resin system. Brominated compounds are commonly used, often in combination with antimony trioxide as a synergist. These additives work by releasing flame-inhibiting gases when exposed to heat, thereby suppressing combustion. The careful balance of these flame retardants ensures that FR4 epoxy laminates meet stringent fire safety standards without compromising other essential properties.

Manufacturing Process: Impregnation, Pressing, and Curing

Impregnation: Saturating the Glass Cloth

The manufacturing process begins with the impregnation stage, where the glass fiber cloth is saturated with the epoxy resin mixture. This is typically achieved using a continuous process where the cloth is passed through a bath of liquid resin. The resin bath composition is carefully controlled to ensure the correct ratio of resin to glass fiber in the final laminate. As the cloth emerges from the bath, excess resin is removed using rollers or doctor blades to achieve a uniform coating. The impregnated cloth, now referred to as prepreg, is then partially cured or B-staged to achieve a tacky, semi-solid state that facilitates handling in subsequent steps.

Pressing: Forming the Laminate Structure

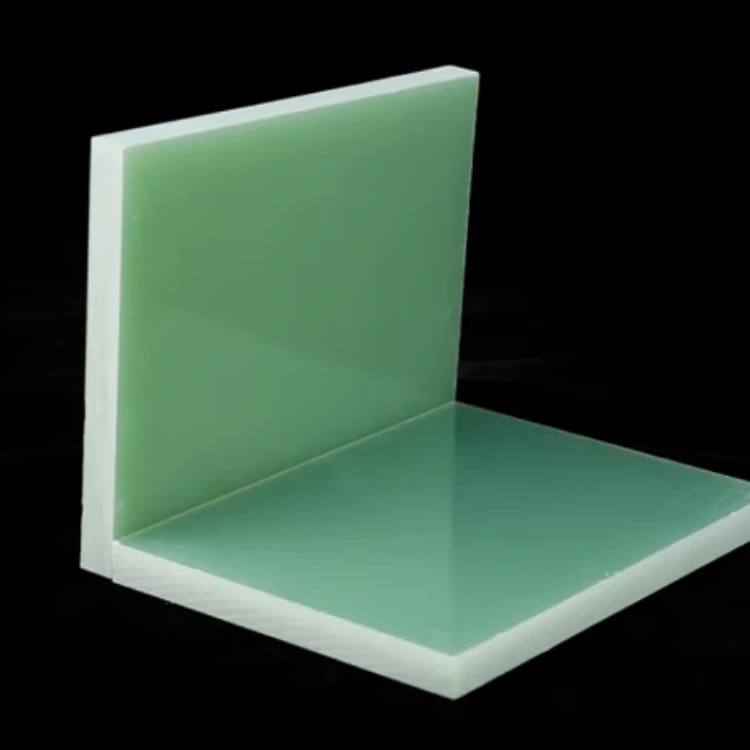

The pressing stage involves stacking multiple layers of prepreg to achieve the desired thickness of the final laminate. These layers are carefully aligned and placed between polished steel plates or continuous belts in a hydraulic press or a continuous laminator. Heat and pressure are applied simultaneously, typically at temperatures ranging from 150°C to 180°C and pressures of 200 to 400 psi. This process causes the resin to flow and fill any voids between the glass fibers, ensuring a uniform, dense structure. The number of prepreg layers and the pressing conditions are precisely controlled to achieve the specific thickness and properties required for different grades of FR4 laminate.

Curing: Finalizing the Laminate Properties

The curing stage is critical in determining the final properties of the FR4 epoxy laminate. During this phase, the epoxy resin undergoes a chemical reaction known as cross-linking, where individual polymer chains form a three-dimensional network. This transformation from a thermoplastic to a thermoset state imparts the laminate with its characteristic heat resistance and mechanical stability. The curing process is carefully controlled in terms of temperature and duration to ensure complete cross-linking without thermal degradation of the resin or glass fibers. Post-curing treatments may also be applied to further enhance specific properties of the laminate.

Quality Control and Compliance in Laminate Fabrication

Testing Electrical Properties

Quality control in FR4 laminate production involves rigorous testing of electrical properties to ensure compliance with industry standards. Key parameters evaluated include dielectric strength, which measures the laminate's ability to withstand high voltages without breakdown. This is typically tested using a high-voltage dielectric strength tester. Another crucial property is the dielectric constant, which affects signal propagation in high-frequency applications. This is measured using resonant cavity methods or parallel plate capacitance techniques. Additionally, the dissipation factor, which indicates energy losses in the material, is assessed using precision LCR meters. These electrical tests are performed on samples taken from each production batch to ensure consistency and adherence to specifications.

Mechanical Property Verification

The mechanical integrity of FR4 laminates is paramount for their performance in various applications. Tensile strength testing is conducted using universal testing machines, where samples are subjected to increasing loads until failure. Flexural strength, which is critical for applications where the laminate may experience bending stresses, is evaluated through three-point or four-point bending tests. Impact resistance is assessed using methods like the Izod impact test, providing insights into the material's toughness. Additionally, thermal stress testing, such as the solder float test, is performed to evaluate the laminate's ability to withstand the high temperatures encountered during soldering processes without delamination or blistering.

Flame Retardancy and Environmental Compliance

Given the critical role of flame retardancy in FR4 epoxy laminates, extensive testing is conducted to verify this property. The UL 94 vertical burn test is a standard method used to classify the flame-retardant characteristics of the material. In this test, samples are exposed to a controlled flame, and their burning behavior is observed and timed. FR4 laminates typically achieve a V-0 rating, indicating the highest level of flame retardancy. Furthermore, with increasing environmental regulations, manufacturers must ensure compliance with standards such as RoHS (Restriction of Hazardous Substances). This involves testing for restricted substances like lead, mercury, and certain flame retardants using techniques such as X-ray fluorescence spectroscopy or gas chromatography-mass spectrometry.

Conclusion

The production of FR4 epoxy laminate is a sophisticated process that combines advanced materials science with precision manufacturing techniques. From the careful selection of raw materials to the intricate steps of impregnation, pressing, and curing, each stage plays a crucial role in developing the laminate's unique properties. The rigorous quality control measures and compliance testing ensure that FR4 laminates meet the exacting standards required for their diverse applications. As technology continues to evolve, the manufacturing processes for FR4 laminates are likely to see further refinements, potentially leading to enhanced performance characteristics and new applications in the future.

Contact Us

For more information about our FR4 epoxy laminate products and manufacturing capabilities, please contact us at info@jhd-material.com. Our team of experts is ready to assist you with your specific laminate requirements and provide tailored solutions for your projects.

References

1. Smith, J. (2022). Advanced Manufacturing Techniques in Composite Materials. Journal of Materials Engineering and Performance, 31(8), 6123-6135.

2. Johnson, L., & Brown, R. (2021). Flame Retardancy in Epoxy-Based Laminates: Mechanisms and Testing Methods. Fire and Materials, 45(3), 342-356.

3. Chen, Y., et al. (2023). Recent Advances in FR4 Laminate Production for High-Frequency Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(6), 1089-1102.

4. Williams, A. (2020). Quality Control Strategies in Printed Circuit Board Materials. International Journal of Quality & Reliability Management, 37(4), 679-695.

5. Thompson, E., & Davis, M. (2022). Environmental Considerations in FR4 Laminate Manufacturing: A Life Cycle Assessment. Journal of Cleaner Production, 330, 129751.

6. Lee, S., et al. (2021). Optimization of Curing Processes for High-Performance Epoxy Laminates. Polymer Engineering & Science, 61(5), 1312-1324.