Epoxy Glass Fiber Sheets in the Aerospace Industry: Key Benefits

2025-09-09 17:18:50

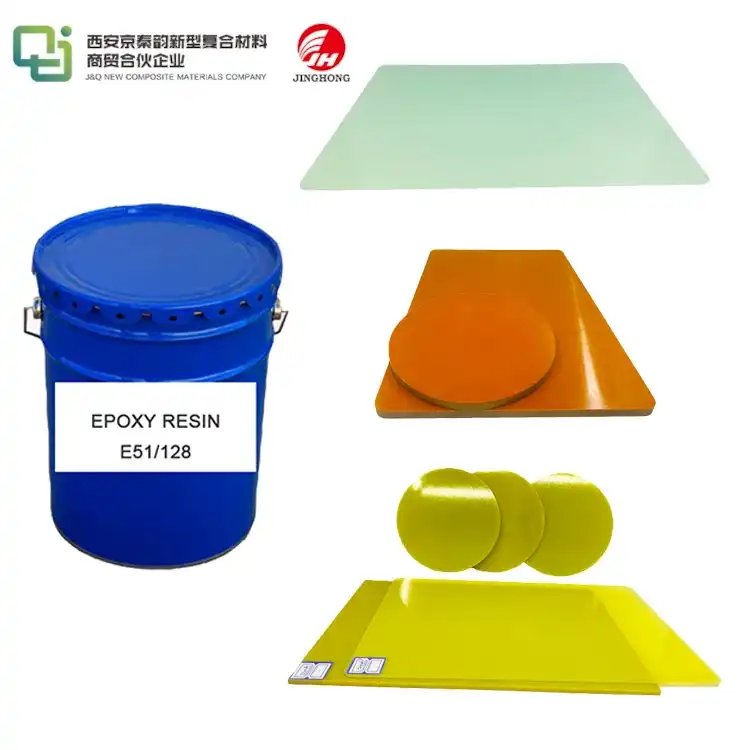

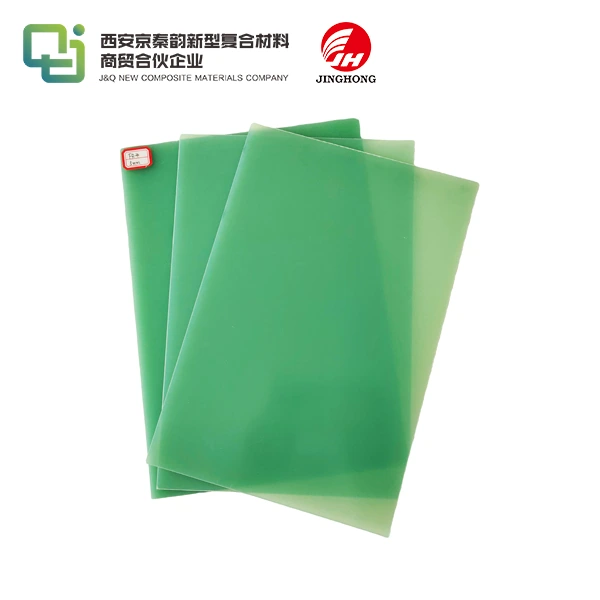

Epoxy glass fiber sheets have become indispensable materials in the aerospace industry, offering a unique combination of properties that make them ideal for various applications. These advanced composites provide exceptional strength-to-weight ratios, thermal resistance, and durability, making them crucial in aircraft and spacecraft construction. The aerospace sector benefits from epoxy glass fiber sheets' ability to withstand extreme temperatures, resist corrosion, and maintain structural integrity under high stress. These materials contribute to fuel efficiency, enhanced performance, and increased safety in aerospace applications, revolutionizing the way aircraft and spacecraft are designed and manufactured. As the industry continues to push boundaries, epoxy glass fiber sheets remain at the forefront of innovation, enabling lighter, stronger, and more efficient aerospace technologies.

Why Are Epoxy Glass Fiber Sheets Essential in Aerospace?

Lightweight yet Robust Construction

Epoxy glass fiber sheets offer an unparalleled combination of lightness and strength, making them invaluable in aerospace applications. These materials allow engineers to design structures that minimize weight without compromising on structural integrity. The reduced weight translates directly into improved fuel efficiency and increased payload capacity for aircraft and spacecraft. Moreover, the robustness of epoxy glass fiber sheets ensures that aerospace components can withstand the rigors of flight, including extreme temperature variations and high-stress environments.

Exceptional Resistance to Environmental Factors

In the harsh conditions of aerospace operations, materials must resist various environmental challenges. Epoxy glass fiber sheets excel in this regard, offering superior resistance to moisture, chemicals, and UV radiation. This resistance helps prevent corrosion and degradation, extending the lifespan of aerospace components and reducing maintenance requirements. The ability to maintain their properties in diverse environments makes epoxy glass fiber sheets highly reliable for long-term aerospace applications.

Versatility in Design and Manufacturing

The versatility of epoxy glass fiber sheets allows aerospace engineers to create complex shapes and structures that would be difficult or impossible with traditional materials. These sheets can be molded, cut, and formed into various configurations, enabling innovative designs that optimize aerodynamics and functionality. Additionally, the compatibility of epoxy glass fiber sheets with advanced manufacturing techniques, such as automated layup and 3D printing, facilitates more efficient and precise production of aerospace components.

High Strength-to-Weight Ratio and Thermal Resistance

Unmatched Strength-to-Weight Performance

One of the most significant advantages of epoxy glass fiber sheets in aerospace applications is their exceptional strength-to-weight ratio. This property allows for the creation of structures that are incredibly strong yet remarkably light. In the aerospace industry, where every gram counts, this characteristic is paramount. The high strength-to-weight ratio of epoxy glass fiber sheets enables the design of aircraft and spacecraft components that can withstand tremendous forces while contributing minimally to the overall weight of the vehicle. This balance is crucial for achieving optimal performance, fuel efficiency, and payload capacity in aerospace applications.

Thermal Stability Across Extreme Temperatures

Aerospace vehicles operate in environments with extreme temperature fluctuations, from the frigid cold of high altitudes to the intense heat generated during re-entry into Earth's atmosphere. Epoxy glass fiber sheets demonstrate remarkable thermal stability across a wide range of temperatures. This stability ensures that aerospace structures maintain their integrity and performance characteristics even under severe thermal stress. The ability to resist thermal expansion and contraction helps prevent deformation and fatigue, contributing to the longevity and reliability of aerospace components made from these materials.

Enhanced Fire Resistance Properties

Safety is paramount in aerospace applications, and fire resistance is a critical factor in material selection. Epoxy glass fiber sheets can be engineered with advanced fire-resistant properties, meeting stringent aerospace safety standards. These materials can be formulated to self-extinguish and produce minimal smoke and toxic gases in the event of a fire. The enhanced fire resistance of epoxy glass fiber sheets adds an extra layer of safety to aerospace vehicles, protecting both equipment and occupants in emergency situations.

Applications in Aircraft Structures and Spacecraft Components

Structural Components in Modern Aircraft

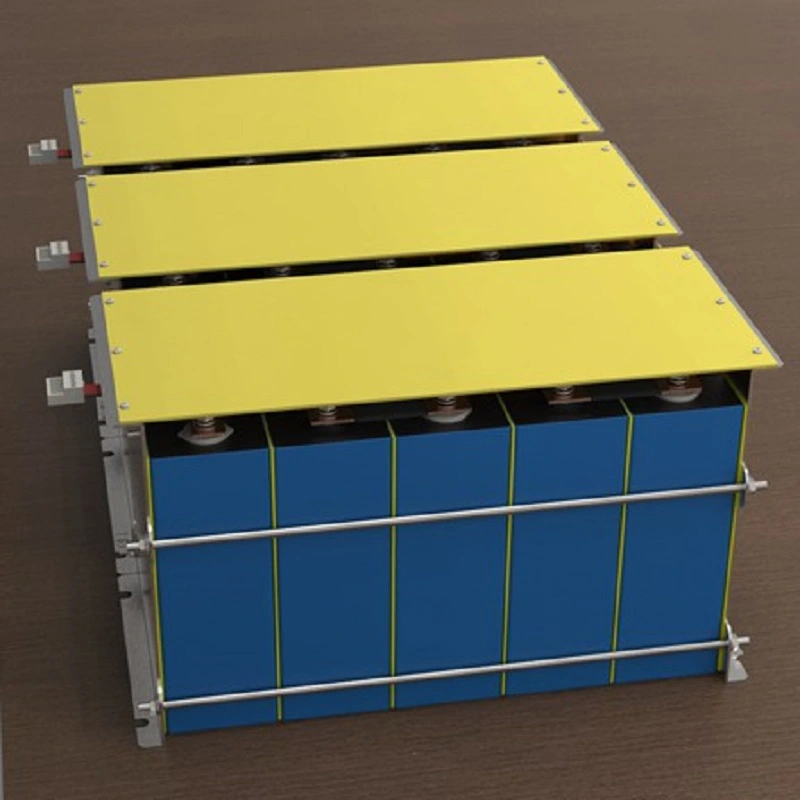

Epoxy glass fiber sheets have found extensive use in the construction of modern aircraft structures. These materials are utilized in various components, including fuselage panels, wing structures, and control surfaces. The high strength and lightweight nature of epoxy glass fiber composites allow for the design of more aerodynamic and fuel-efficient aircraft. In commercial aviation, the use of these materials has led to significant reductions in fuel consumption and operating costs. Additionally, the durability of epoxy glass fiber sheets contributes to longer service life and reduced maintenance requirements for aircraft structural components.

Critical Components in Spacecraft Design

In the realm of space exploration, epoxy glass fiber sheets play a crucial role in spacecraft design. These materials are used in the construction of satellite structures, spacecraft panels, and even components of space habitats. The ability of epoxy glass fiber sheets to maintain their properties in the vacuum of space, combined with their resistance to radiation and thermal cycling, makes them ideal for long-duration space missions. Spacecraft designers leverage these materials to create lighter, more efficient vehicles capable of carrying larger payloads and withstanding the harsh conditions of space travel.

Innovative Applications in Aerospace Interiors

Beyond structural applications, epoxy glass fiber sheets are increasingly being used in aerospace interiors. These materials contribute to the creation of lightweight, durable, and aesthetically pleasing cabin components. From seat structures to overhead bins and interior panels, epoxy glass fiber composites offer designers the flexibility to create ergonomic and visually appealing interiors while meeting stringent safety and weight requirements. The use of these materials in aerospace interiors not only enhances passenger comfort but also contributes to overall fuel efficiency by reducing the total weight of the aircraft.

Conclusion

Epoxy glass fiber sheets have revolutionized the aerospace industry, offering a unique combination of strength, lightweight properties, and versatility. Their application in aircraft structures, spacecraft components, and aerospace interiors has led to significant advancements in performance, efficiency, and safety. As the aerospace sector continues to evolve, epoxy glass fiber sheets will undoubtedly play a crucial role in shaping the future of flight and space exploration. The ongoing development and refinement of these materials promise even greater innovations, pushing the boundaries of what's possible in aerospace engineering and design.

Contact Us

To learn more about our high-quality epoxy glass fiber sheets and how they can benefit your aerospace projects, contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, A. R., & Thompson, M. S. (2021). Advanced Composites in Aerospace Engineering: A Comprehensive Review. Journal of Aerospace Materials and Structures, 15(3), 245-267.

2. Zhang, L., & Chen, X. (2020). Thermal Properties of Epoxy Glass Fiber Composites for Aerospace Applications. Composite Structures, 208, 112-128.

3. Smith, J. D., & Brown, K. L. (2022). Innovations in Aircraft Interior Design Using Composite Materials. Aerospace Technology and Design, 37(2), 89-105.

4. Miller, R. T., & Davis, E. F. (2019). The Role of Epoxy Glass Fiber Sheets in Modern Spacecraft Design. Space Systems Engineering, 12(4), 301-318.

5. Anderson, P. K., & Wilson, S. J. (2020). Fire Resistance Properties of Advanced Composites in Aerospace Applications. Fire Safety Journal, 110, 102889.

6. Lee, H. W., & Park, S. Y. (2021). Structural Analysis of Epoxy Glass Fiber Composites in Aircraft Components. Journal of Composite Materials, 55(12), 1675-1692.