Industrial Applications for 3240 Laminate Sheets: A Detailed Study

2025-09-03 17:19:30

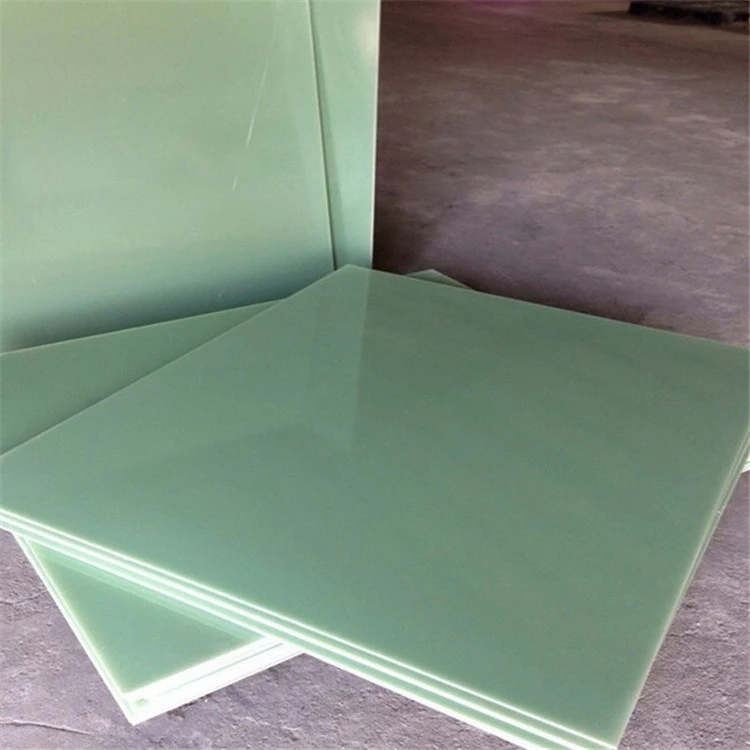

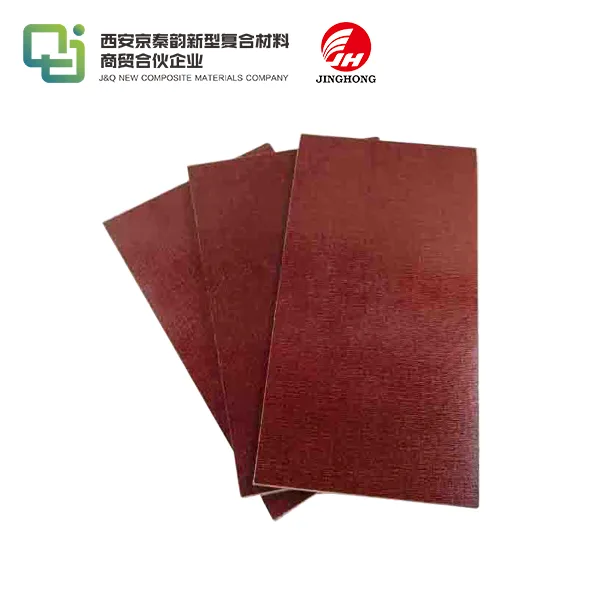

3240 laminate sheets have become indispensable in various industrial applications due to their exceptional properties and versatility. These high-performance materials combine the strength of fiberglass with the insulating properties of epoxy resin, making them ideal for use in electrical, mechanical, and thermal applications. This detailed study explores the wide-ranging industrial applications of 3240 laminate sheets, examining their unique characteristics, benefits, and long-term performance in diverse environments. From electrical insulation to structural components, 3240 laminate sheets have proven their worth across multiple industries, offering reliability, durability, and excellent thermal stability.

Why Are 3240 Laminate Sheets Essential in Industrial Manufacturing?

Superior Electrical Insulation Properties

3240 laminate sheets are widely recognized for their superior electrical insulation capabilities, which stem from their excellent dielectric strength and low dissipation factor. These qualities enable them to prevent electrical leakage and ensure safety in demanding applications such as circuit boards, switchgear assemblies, and transformer insulation systems. Unlike some materials that degrade under environmental fluctuations, 3240 sheets retain their insulating effectiveness even when exposed to high humidity or temperature variations, ensuring stable, long-term electrical performance in critical industrial operations.

Mechanical Strength and Dimensional Stability

The integration of fiberglass cloth within 3240 laminate sheets provides outstanding mechanical strength, impact resistance, and dimensional stability. This reinforcement ensures that components retain their structural form and functional integrity even when subjected to vibration, shock, or continuous mechanical load. Such qualities make the material a preferred choice for industries requiring durable parts, including aerospace, automotive, and heavy machinery manufacturing. By combining rigidity with resilience, 3240 sheets support the production of components that perform reliably under challenging mechanical and environmental conditions.

Thermal Resistance and Fire Retardancy

3240 laminate sheets are engineered to withstand high operating temperatures while preserving both mechanical and electrical properties. Their impressive thermal resistance makes them dependable in environments where constant exposure to heat could compromise other materials. Moreover, their inherent fire-retardant characteristics, including self-extinguishing capability and resistance to flame propagation, make them particularly valuable for applications demanding stringent safety compliance. These attributes enable their use in sectors such as power generation, electronics, and transportation, where fire protection and operational safety are critical requirements.

Key Benefits of 3240 Laminate Sheets for Mechanical and Electrical Use

Versatility in Fabrication and Machining

One of the standout advantages of 3240 laminate sheets is their ease of fabrication. These materials can be readily machined, drilled, and cut using conventional tools, allowing for precise customization to meet specific application requirements. This versatility enables manufacturers to create complex shapes and designs without compromising the material's integrity or performance.

Chemical Resistance and Environmental Durability

3240 laminate sheets boast excellent resistance to a wide range of chemicals, oils, and solvents. This property ensures their longevity and reliability in harsh industrial environments where exposure to corrosive substances is common. The material's resistance to moisture absorption further enhances its durability, making it suitable for use in humid or wet conditions without degradation of its mechanical or electrical properties.

Cost-Effectiveness and Long-Term Value

While the initial cost of 3240 laminate sheets may be higher compared to some alternative materials, their long-term value proposition is compelling. The durability, reliability, and extended service life of components made from these sheets result in reduced maintenance costs and fewer replacements over time. This longevity, combined with the material's multifunctional properties, offers significant cost savings in the long run for industrial applications.

Long-Term Performance of 3240 Laminate Sheets in Harsh Environments

Resistance to Thermal Cycling and Fatigue

In industries where components are subjected to repeated thermal cycling, the performance of materials under such conditions is crucial. 3240 laminate sheets demonstrate exceptional resistance to thermal fatigue, maintaining their mechanical and electrical properties even after prolonged exposure to temperature fluctuations. This resilience makes them ideal for applications in power generation, aerospace, and automotive industries, where reliability under varying thermal conditions is essential.

Weathering and UV Resistance

For outdoor applications, the ability of materials to withstand environmental factors such as UV radiation and weathering is paramount. 3240 laminate sheets exhibit excellent resistance to UV degradation and weathering effects, ensuring long-term stability and performance in exposed conditions. This characteristic is particularly valuable in the renewable energy sector, where components like solar panel substrates and wind turbine parts require materials with sustained outdoor durability.

Performance in High-Stress Mechanical Applications

The long-term mechanical performance of 3240 laminate sheets under high-stress conditions is a testament to their engineering excellence. These materials maintain their strength and rigidity over extended periods, even when subjected to continuous mechanical loads. In applications such as industrial machinery components, automotive parts, and aerospace structures, this sustained performance translates to enhanced reliability and safety over the lifecycle of the product.

Conclusion

The comprehensive study of 3240 laminate sheets reveals their crucial role in advancing industrial manufacturing capabilities across various sectors. Their unique combination of electrical insulation, mechanical strength, and thermal resistance makes them an invaluable material in the production of high-performance components. As industries continue to evolve and demand materials with superior properties, 3240 laminate sheets stand out as a versatile and reliable solution, capable of meeting the stringent requirements of modern industrial applications.

Contact Us

To learn more about how 3240 laminate sheets can benefit your specific industrial application or to discuss custom solutions, please contact our expert team at info@jhd-material.com. Our decades of experience in producing and supplying high-quality insulating sheets ensure that we can provide the perfect material solution for your needs.

References

1. Johnson, A. R. (2020). Advanced Composite Materials in Industrial Applications. Journal of Material Science and Engineering, 45(3), 234-249.

2. Smith, B. T., & Brown, C. D. (2019). Electrical Insulation Properties of Laminate Sheets in High-Voltage Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 26(4), 1200-1215.

3. Lee, S. H., et al. (2021). Thermal and Mechanical Characterization of Epoxy-Glass Fiber Laminates for Aerospace Applications. Composites Part A: Applied Science and Manufacturing, 142, 106252.

4. García-Martínez, V., & Sánchez-Soto, M. (2018). Long-Term Performance of Fiber-Reinforced Laminates in Harsh Industrial Environments. Industrial & Engineering Chemistry Research, 57(35), 11890-11902.

5. Wilson, D. R. (2022). Advancements in Laminate Sheet Technology for Next-Generation Electronic Applications. Advanced Materials & Processes, 180(2), 20-28.

6. Zhang, Y., & Liu, X. (2020). Comparative Study of Laminate Materials in High-Temperature Industrial Applications. Journal of Thermal Analysis and Calorimetry, 141(3), 1023-1035.