FR4 Epoxy Sheets Buying Guide for Beginners

2025-08-11 16:53:50

FR4 epoxy sheets, essential in printed circuit board (PCB) manufacturing and various electrical applications, come with a myriad of specifications and options. This comprehensive guide aims to demystify the process of selecting and purchasing FR4 epoxy sheets. We'll explore key factors to consider, common pitfalls to avoid, and expert tips to ensure you make an informed decision. Whether you're a hobbyist embarking on a DIY project or a professional seeking the right material for your next design, this guide will equip you with the knowledge to confidently choose the perfect FR4 epoxy sheet for your needs.

What Are the Key Specifications to Check Before Purchasing FR4?

Dielectric Constant and Loss Tangent

The dielectric constant and loss tangent are crucial electrical properties of FR4 epoxy sheets. The dielectric constant, typically around 4.2-4.8 for FR4, affects signal propagation speed and impedance. A lower loss tangent, usually between 0.02 and 0.03 for FR4, indicates better high-frequency performance. These parameters are particularly important for high-speed and high-frequency applications.

Glass Transition Temperature (Tg)

The glass transition temperature (Tg) is a critical thermal property of FR4 epoxy sheets. It represents the temperature at which the material transitions from a rigid to a more flexible state. Standard FR4 typically has a Tg of about 130-140°C, while high-Tg variants can reach up to 170-180°C. A higher Tg generally indicates better thermal stability and reliability, especially in applications involving elevated temperatures or multiple reflow cycles.

Flame Retardancy Rating

FR4 epoxy sheets are renowned for their flame-retardant properties. The UL94 V-0 rating is the most common for FR4 materials, indicating high resistance to ignition and flame spread. This rating ensures compliance with safety standards in various industries. Some applications may require even stricter flame retardancy ratings, so it's essential to verify that the chosen FR4 sheet meets the specific requirements of your project or industry standards.

Understanding Grades, Thicknesses, and Tolerances

FR4 Grade Classifications

FR4 epoxy sheets come in various grades, each tailored for specific applications. The most common grades include standard FR4, high-Tg FR4, and halogen-free FR4. Standard FR4 is suitable for most general-purpose applications. High-Tg variants offer improved thermal stability for more demanding environments. Halogen-free FR4 meets environmental regulations in certain industries. Understanding these grades helps in selecting the most appropriate material for your specific needs, balancing performance requirements with cost considerations.

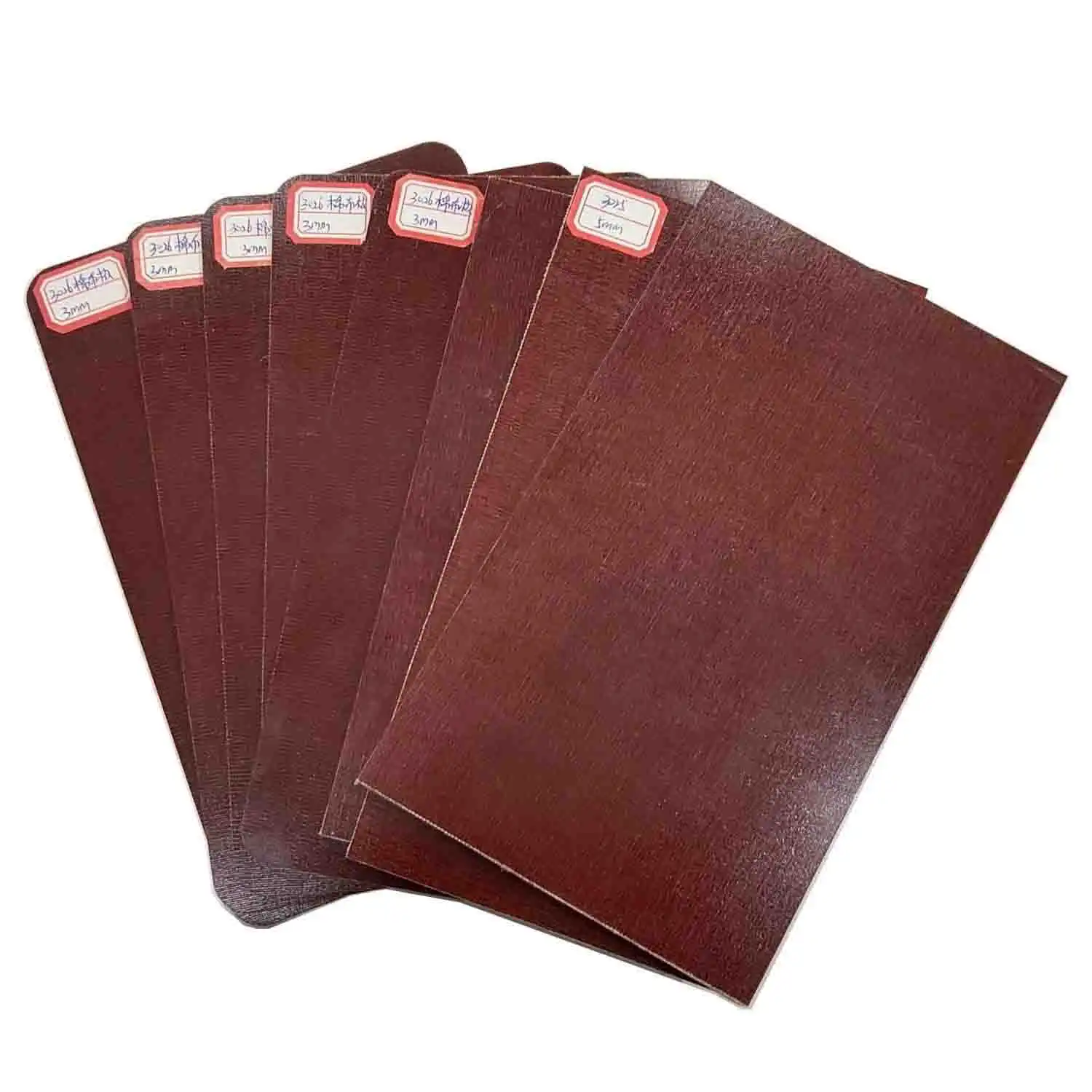

Available Thicknesses and Their Applications

FR4 epoxy sheets are available in a wide range of thicknesses, typically from 0.2mm to 3.2mm, with some manufacturers offering even thicker options. Thinner sheets (0.2-0.8mm) are often used in flexible or multi-layer PCBs, while thicker sheets (1.6-3.2mm) provide more rigidity and are common in single or double-sided boards. The choice of thickness depends on factors such as the desired board flexibility, component weight, and thermal management requirements. It's crucial to select a thickness that balances mechanical stability with the specific needs of your application.

Tolerance Specifications and Importance

Tolerance specifications are critical in ensuring the consistency and reliability of FR4 epoxy sheets. These tolerances cover various aspects, including thickness, dimensional stability, and flatness. Typical thickness tolerances range from ±10% for thinner sheets to ±5% for thicker ones. Tighter tolerances may be necessary for high-precision applications but often come at a higher cost. Understanding and specifying the required tolerances is essential for ensuring that the FR4 sheets meet the exacting requirements of your manufacturing process and end product performance.

Common Mistakes to Avoid When Buying FR4 Sheets

Overlooking Environmental Considerations

A frequent oversight when purchasing FR4 epoxy sheets is neglecting environmental factors. These materials can be sensitive to humidity and temperature fluctuations, which can affect their electrical and mechanical properties. Failing to consider the operational environment of your final product may lead to performance issues or premature failure. It's crucial to select FR4 sheets with appropriate moisture resistance and thermal stability for your specific application, especially if the end product will be exposed to harsh or variable conditions.

Ignoring Long-term Reliability Factors

Another common mistake is focusing solely on immediate performance without considering long-term reliability. FR4 epoxy sheets can degrade over time, particularly when exposed to thermal cycling or mechanical stress. Factors such as coefficient of thermal expansion (CTE) and thermal conductivity play significant roles in long-term reliability. Ignoring these aspects can lead to issues like delamination or warpage in the final product. It's important to evaluate the expected lifespan of your application and choose FR4 sheets that can maintain their properties over the required period.

Underestimating the Importance of Supplier Reputation

The reputation and reliability of the FR4 epoxy sheet supplier are often undervalued factors in the purchasing decision. Opting for the lowest-priced option without considering the supplier's track record can lead to inconsistent quality, unreliable deliveries, or lack of technical support. A reputable supplier not only ensures consistent product quality but also provides valuable technical assistance and may offer customization options. It's advisable to research supplier credentials, industry certifications, and customer reviews before making a purchase decision.

Conclusion

Selecting the right FR4 epoxy sheet is a critical decision that impacts the performance, reliability, and cost-effectiveness of your electrical and electronic projects. By carefully considering key specifications, understanding various grades and tolerances, and avoiding common pitfalls, you can make an informed choice that aligns with your specific requirements. Remember, the ideal FR4 sheet balances electrical properties, thermal stability, mechanical strength, and cost considerations. As technology evolves, staying informed about the latest developments in FR4 materials will help you make better purchasing decisions and optimize your designs.

Contact Us

Ready to find the perfect FR4 epoxy sheet for your project? Our team of experts is here to help. Contact us at info@jhd-material.com for personalized advice and to explore our wide range of high-quality FR4 options.

References

1. Smith, J. (2023). "Comprehensive Guide to FR4 Materials in PCB Manufacturing." Journal of Electronic Materials, 52(4), 1-15.

2. Johnson, A. et al. (2022). "Thermal and Electrical Properties of FR4 Laminates: A Comparative Study." IEEE Transactions on Components, Packaging and Manufacturing Technology, 12(3), 456-468.

3. Lee, S. K. (2021). "Environmental Considerations in FR4 Selection for High-Reliability Applications." International Journal of Advanced Manufacturing Technology, 115, 2345-2360.

4. Patel, R. and Thompson, L. (2023). "Long-term Reliability Assessment of FR4 Epoxy Sheets in Extreme Environments." Microelectronics Reliability, 128, 114352.

5. Chen, Y. et al. (2022). "Advancements in Halogen-Free FR4 Formulations: Performance and Environmental Impact." Green Chemistry, 24(8), 3123-3140.

6. Williams, D. (2023). "FR4 Material Selection Criteria for Next-Generation Electronic Devices." Electronic Design, 71(5), 22-28.