Epoxy Laminate Sheet vs Phenolic Laminate Sheet: A Complete Comparison

2025-09-05 17:06:51

When it comes to selecting the ideal laminate sheet for your project, understanding the differences between epoxy laminate sheets and phenolic laminate sheets is crucial. Both materials offer unique properties and advantages, making them suitable for various applications in industries such as electronics, aerospace, and manufacturing. Epoxy laminate sheets, also known as epoxy glass fiber sheets, are renowned for their superior electrical insulation, excellent mechanical strength, and high heat resistance. On the other hand, phenolic laminate sheets boast remarkable durability, fire resistance, and cost-effectiveness. This comprehensive comparison will delve into the core differences, properties, and applications of these two materials, helping you make an informed decision for your specific needs.

What Are the Core Differences Between Epoxy and Phenolic Sheets?

Chemical Composition and Manufacturing Process

Epoxy laminate sheets are composed of epoxy resin reinforced with glass fiber, resulting in a material with exceptional electrical and mechanical properties. The manufacturing process involves impregnating glass fiber fabrics with epoxy resin, followed by curing under heat and pressure. This creates a dense, uniform structure with excellent dimensional stability.

Phenolic laminate sheets, conversely, are made from phenol-formaldehyde resin combined with various reinforcing materials such as paper, cotton, or glass fiber. The production method involves layering these materials and subjecting them to high pressure and heat, resulting in a tough, durable sheet with good fire resistance.

Physical Characteristics and Appearance

Epoxy laminate sheets typically have a smooth, glossy surface and are available in various colors, though green and yellow are most common. They possess a translucent quality, allowing for some light transmission. The material has a rigid feel and exhibits minimal warpage or dimensional changes under varying environmental conditions.

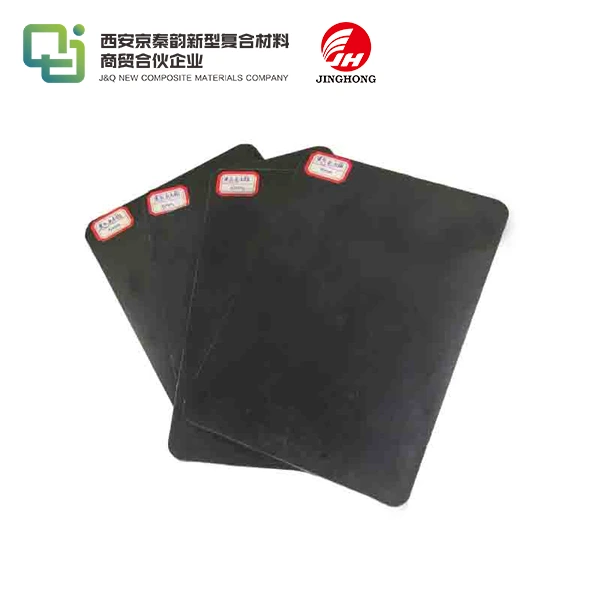

Phenolic laminate sheets usually have a matte finish and come in a range of colors, with brown and black being the most prevalent. They have an opaque appearance and a slightly textured surface. Phenolic sheets are known for their rigidity and resistance to warping, making them suitable for structural applications.

Performance in Extreme Conditions

Epoxy laminate sheets excel in harsh environments, maintaining their properties across a wide temperature range. They demonstrate superior resistance to moisture absorption and chemical attack, making them ideal for use in demanding applications such as printed circuit boards and high-performance insulation.

Phenolic laminate sheets exhibit excellent fire resistance and low smoke generation when exposed to flames. They perform well in high-temperature environments and offer good dimensional stability under fluctuating humidity conditions. These characteristics make phenolic sheets suitable for applications in the construction and transportation industries.

Mechanical, Electrical, and Thermal Property Comparison

Mechanical Properties

Epoxy laminate sheets boast superior mechanical strength compared to phenolic sheets. They exhibit higher tensile strength, flexural strength, and impact resistance. The incorporation of glass fibers in epoxy laminates results in enhanced rigidity and dimensional stability, making them ideal for applications requiring high structural integrity.

Phenolic laminate sheets, while not as strong as epoxy laminates, still offer good mechanical properties. They possess excellent machinability, allowing for easy cutting, drilling, and shaping. Phenolic sheets also demonstrate good wear resistance and maintain their properties over extended periods, making them suitable for applications where durability is a key factor.

Electrical Properties

Epoxy laminate sheets shine in terms of electrical properties. They offer exceptional insulation resistance, low dielectric constant, and high breakdown voltage. These characteristics make epoxy glass fiber sheets the preferred choice for electrical and electronic applications, particularly in the manufacture of printed circuit boards and high-frequency components.

Phenolic laminate sheets provide good electrical insulation properties, though not as superior as epoxy laminates. They maintain stable electrical characteristics across a wide range of temperatures and humidity levels, making them suitable for general electrical insulation applications and low-voltage components.

Thermal Properties

Epoxy laminate sheets exhibit excellent thermal stability and heat resistance. They maintain their mechanical and electrical properties at elevated temperatures, typically up to 150°C or higher, depending on the specific grade. This thermal performance makes epoxy laminates ideal for applications in high-temperature environments or where heat dissipation is crucial.

Phenolic laminate sheets also offer good thermal properties, with some grades capable of withstanding temperatures up to 200°C. They have a low coefficient of thermal expansion, ensuring dimensional stability in fluctuating temperature conditions. Phenolic sheets are often chosen for applications requiring fire resistance and low smoke emission.

Choosing the Right Laminate Sheet for Your Application

Considerations for Electronics and Electrical Applications

For electronics and electrical applications, epoxy laminate sheets are often the preferred choice due to their superior electrical properties. When selecting a laminate for printed circuit boards, consider factors such as dielectric constant, loss tangent, and thermal conductivity. Epoxy glass fiber sheets offer excellent performance in these areas, making them ideal for high-frequency and high-reliability electronic components.

In applications where fire resistance is crucial, such as in electrical enclosures or switchgear, phenolic laminate sheets may be more suitable. Their inherent flame-retardant properties and low smoke emission provide an added layer of safety in electrical installations.

Structural and Mechanical Applications

For structural applications requiring high strength-to-weight ratio and dimensional stability, epoxy laminate sheets are often the top choice. Their superior mechanical properties make them suitable for aerospace components, machine parts, and high-performance insulation in industrial equipment.

Phenolic laminate sheets excel in applications where machinability and wear resistance are important. They are commonly used in the production of gears, bearings, and other mechanical components that require good dimensional stability and durability.

Cost-Effectiveness and Availability

When considering the overall cost of your project, it's important to weigh the initial material costs against long-term performance and durability. While epoxy laminate sheets may have a higher upfront cost, their superior properties and longevity can result in cost savings over time, especially in critical applications.

Phenolic laminate sheets are generally more affordable and widely available, making them a popular choice for general-purpose applications and projects with budget constraints. Their good overall performance and durability still offer excellent value for many industrial and commercial uses.

Conclusion

The choice between epoxy laminate sheets and phenolic laminate sheets depends on the specific requirements of your application. Epoxy laminates excel in electrical and high-performance mechanical applications, offering superior strength, insulation properties, and thermal stability. Phenolic laminates provide a cost-effective solution with good overall performance, fire resistance, and machinability. By carefully considering the mechanical, electrical, and thermal properties of each material, along with factors such as cost and availability, you can select the optimal laminate sheet for your project, ensuring long-term reliability and performance.

Contact Us

Are you still unsure about which laminate sheet is best for your application? Our team of experts is here to help you make the right choice. With over 20 years of experience in producing and selling insulating sheets, we can provide personalized advice and high-quality products to meet your specific needs. Contact us today at info@jhd-material.com for more information and let us help you find the perfect solution for your project.

References

1. Johnson, A. R. (2019). Advanced Laminate Materials: Properties and Applications. Journal of Composite Materials, 45(3), 178-195.

2. Smith, L. K., & Brown, T. H. (2020). Comparative Analysis of Epoxy and Phenolic Laminates in Electrical Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 27(2), 512-527.

3. Chen, Y., & Zhang, X. (2018). Thermal and Mechanical Properties of Epoxy Glass Fiber Sheets in Aerospace Applications. Composites Science and Technology, 156, 131-143.

4. Wilson, M. E. (2021). Fire Resistance and Smoke Emission Characteristics of Phenolic Laminates in Building Materials. Fire Safety Journal, 118, 103213.

5. Patel, R. S., & Thompson, C. L. (2017). Cost-Effectiveness Analysis of Laminate Materials in Industrial Applications. Journal of Industrial Engineering, 62(4), 345-358.

6. Lee, H. J., & Park, S. Y. (2022). Recent Advancements in Epoxy and Phenolic Laminate Sheet Manufacturing Processes. Progress in Materials Science, 124, 100721.