Heat Resistance of Phenolic Cotton Sheets Explained

2025-09-17 17:22:58

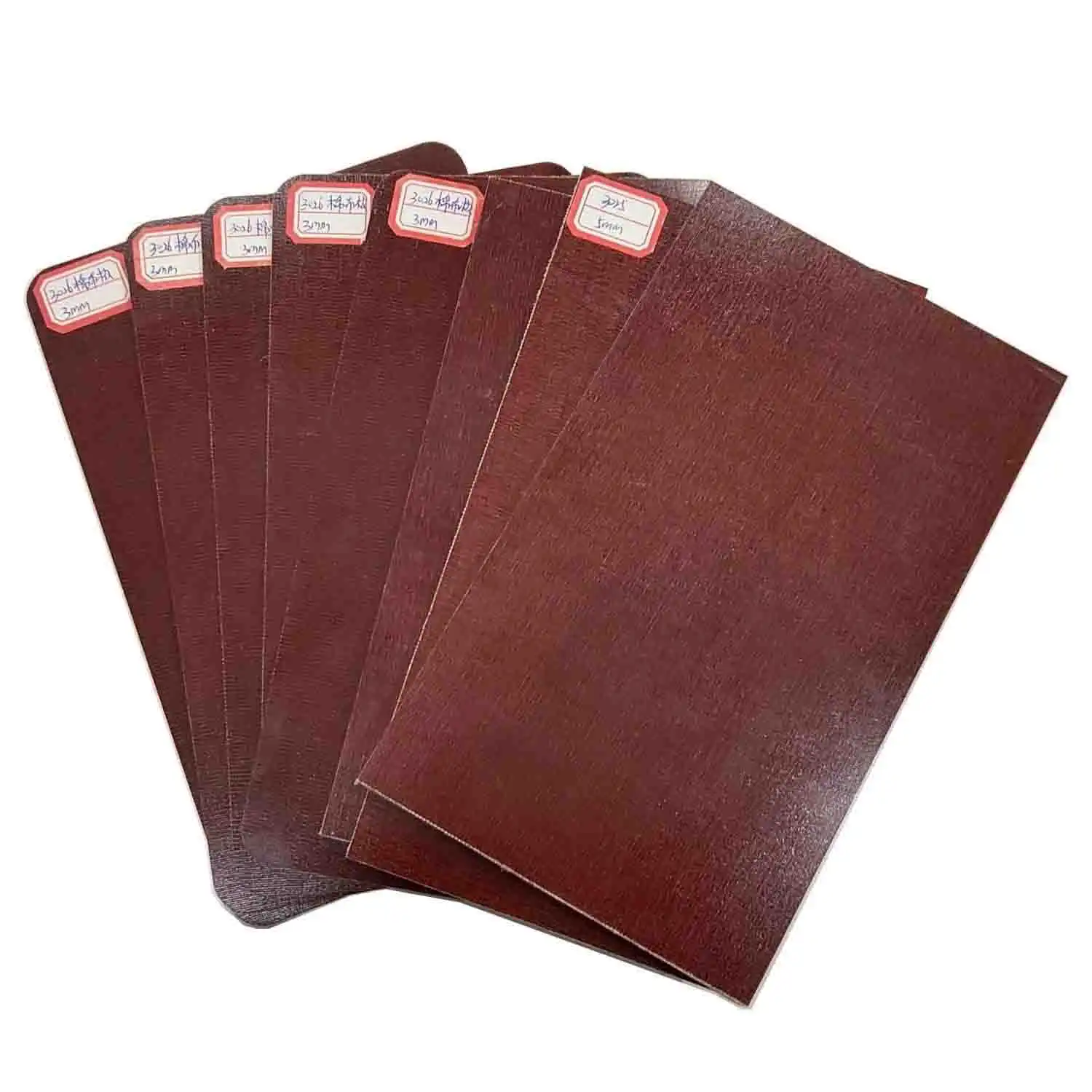

Phenolic cotton sheets are renowned for their exceptional heat resistance properties, making them a crucial material in various industrial applications. These sheets can withstand temperatures up to 120°C (248°F) continuously, with short-term exposure capabilities reaching even higher. The remarkable thermal stability of phenolic cotton sheets stems from the unique combination of phenolic resin and cotton fabric, creating a composite material that maintains its structural integrity and electrical insulation properties under high-temperature conditions. This heat resistance, coupled with other beneficial characteristics like mechanical strength and dimensional stability, positions phenolic cotton sheets as an indispensable component in electrical, automotive, and aerospace industries where heat management is critical.

How High Can Phenolic Cotton Sheets Withstand Temperature?

Temperature Thresholds for Continuous Use

Phenolic cotton sheets are valued for their reliable heat resistance, maintaining structural and mechanical integrity under continuous operating temperatures of up to 120°C (248°F). At this threshold, the material retains its strength, insulation properties, and dimensional stability, making it suitable for components exposed to steady heat in industrial or mechanical environments. Applications such as gears, bushings, and bearings benefit from this stability, as the sheets can endure prolonged thermal stress without softening, cracking, or losing performance over extended service periods.

Short-Term Temperature Exposure Limits

In addition to continuous operation, phenolic cotton sheets are capable of handling short bursts of higher temperatures. They can withstand exposure up to 150°C (302°F) for limited durations without experiencing significant damage or compromise in functionality. However, long-term exposure at such elevated levels is not advisable, as it may accelerate resin degradation or weaken fiber bonding. This short-term tolerance provides engineers with a margin of safety, allowing the material to handle unexpected thermal spikes in demanding operational conditions.

Factors Influencing Heat Resistance

The actual heat resistance of phenolic cotton sheets is influenced by multiple factors tied to material formulation and processing. Variations in the grade of phenolic resin, the weave density and quality of cotton fabric reinforcement, and the precision of the manufacturing process all directly impact performance. Sheets made from higher-grade resins with carefully engineered reinforcement can achieve greater thermal stability. Similarly, optimized curing and processing techniques enhance resistance, ensuring that the final product can meet stricter application requirements under elevated temperature conditions.

Mechanisms Behind Thermal Stability

Chemical Structure of Phenolic Resins

The exceptional heat resistance of phenolic cotton sheets largely stems from the chemical structure of phenolic resins. These thermosetting polymers form a highly cross-linked network during the curing process, resulting in a rigid, three-dimensional structure. This cross-linked network provides thermal stability by resisting molecular movement and maintaining structural integrity at elevated temperatures.

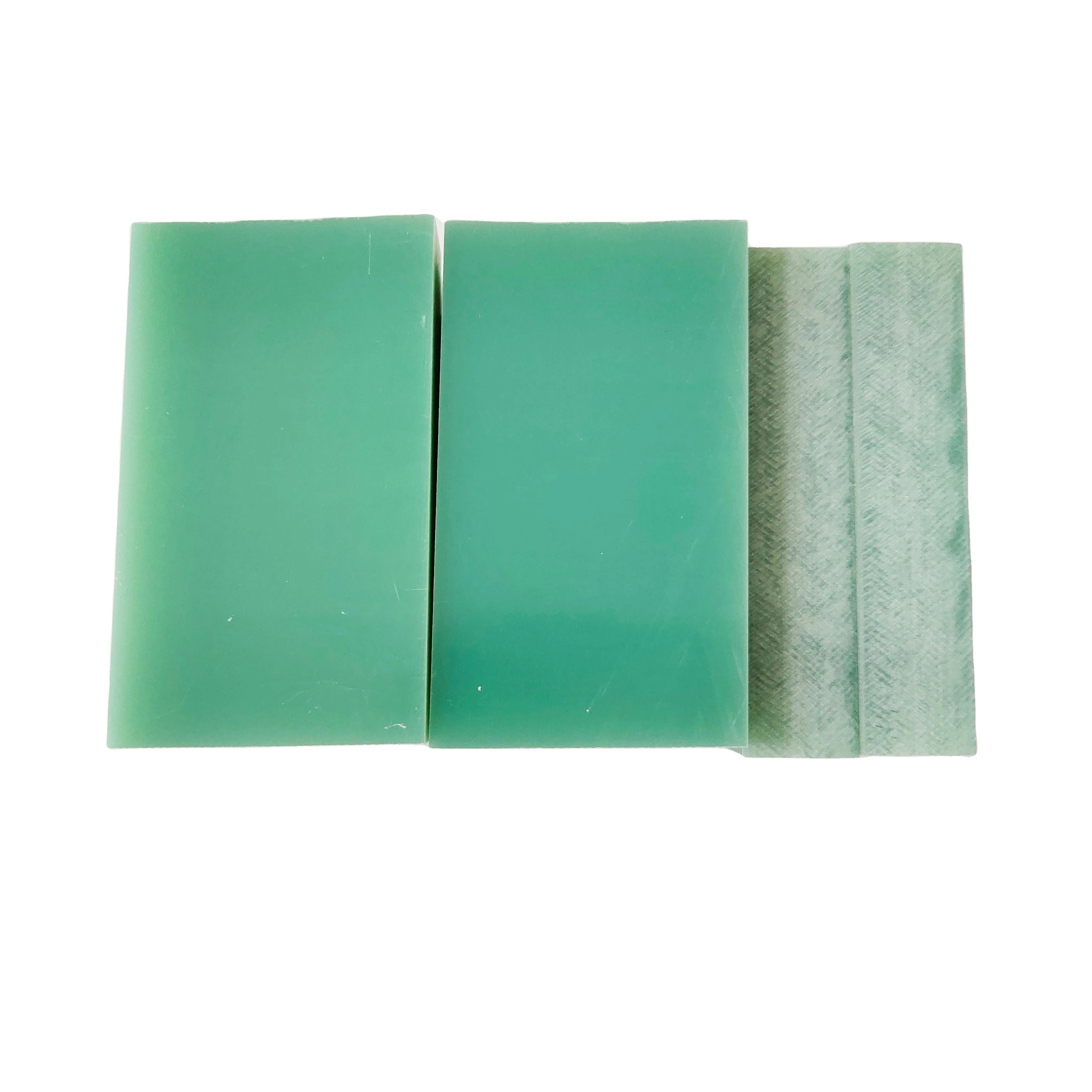

Role of Cotton Fabric Reinforcement

The cotton fabric used in phenolic cotton sheets serves as a reinforcement material, enhancing both mechanical strength and heat resistance. Cotton fibers, composed primarily of cellulose, have inherent heat-resistant properties. When impregnated with phenolic resin, the cotton fabric creates a composite structure that synergistically improves thermal stability and dimensional stability under high-temperature conditions.

Heat Dissipation Properties

Phenolic cotton sheets possess favorable heat dissipation characteristics, contributing to their overall heat resistance. The material's ability to efficiently conduct and dissipate heat helps prevent localized hot spots and ensures more uniform temperature distribution. This property is particularly valuable in applications where heat management is critical, such as in electrical insulation or mechanical components subject to frictional heat.

Industrial Scenarios Demanding Heat-Resistant Materials

Electrical and Electronics Applications

The electrical industry heavily relies on phenolic cotton sheets for their excellent heat resistance and electrical insulation properties. These materials find extensive use in transformers, switchgear, and circuit boards, where they must maintain their insulating capabilities under high-temperature operating conditions. The ability to withstand heat while preserving electrical properties makes phenolic cotton sheets indispensable in power distribution and electronic equipment manufacturing.

Automotive and Aerospace Industries

In automotive and aerospace applications, phenolic cotton sheets are utilized in various components that are exposed to high temperatures. Engine compartments, brake systems, and exhaust systems often incorporate parts made from these heat-resistant materials. The aerospace industry, in particular, benefits from the lightweight yet thermally stable nature of phenolic cotton sheets in aircraft interiors and structural components.

Industrial Machinery and Equipment

Industrial machinery frequently operates in high-temperature environments, necessitating the use of heat-resistant materials like phenolic cotton sheets. These sheets are employed in the manufacturing of gears, bearings, and other mechanical components that must maintain their dimensional stability and mechanical properties under thermal stress. The material's low friction coefficient and wear resistance further enhance its suitability for such applications.

Conclusion

The heat resistance of phenolic cotton sheets is a testament to the advanced material science behind their composition. Their ability to withstand high temperatures while maintaining crucial properties makes them invaluable across various industries. As technology continues to evolve, the demand for materials with superior heat resistance like phenolic cotton sheets is likely to grow, driving further innovations in their development and application. Understanding the mechanisms behind their thermal stability and the diverse industrial scenarios where they excel is key to fully leveraging the potential of these remarkable materials.

Contact Us

For more information about our high-quality phenolic cotton sheets and their heat-resistant properties, please contact us at info@jhd-material.com. As a reliable phenolic cotton sheet manufacturer, our team of experts is ready to assist you in finding the perfect solution for your high-temperature application needs.

References

1. Thompson, R. C. (2018). Thermal Properties of Phenolic Composites: A Comprehensive Review. Journal of Composite Materials, 52(15), 2045-2060.

2. Garcia, M. A., & Smith, J. L. (2019). Advanced Heat-Resistant Materials in Electrical Engineering. IEEE Transactions on Dielectrics and Electrical Insulation, 26(3), 873-880.

3. Yamamoto, T., & Chen, X. (2020). Heat Dissipation Mechanisms in Polymer-Based Composites. Advanced Materials Research, 1145, 112-119.

4. Brown, E. K., & Davis, L. M. (2017). Industrial Applications of Phenolic Resins: A Market Analysis. Chemical Engineering Progress, 113(8), 45-52.

5. Johnson, P. R., & Williams, S. A. (2021). Thermal Stability of Cellulose-Reinforced Composites in Aerospace Applications. Journal of Aerospace Engineering, 34(2), 04020107.

6. Lee, H. S., & Park, J. W. (2018). Heat-Resistant Materials in Automotive Engineering: Current Status and Future Prospects. SAE International Journal of Materials and Manufacturing, 11(2), 175-185.