Epoxy Sheet Buyer’s Guide: Grades, Strength, and Temperature Limits

2025-12-11 16:56:36

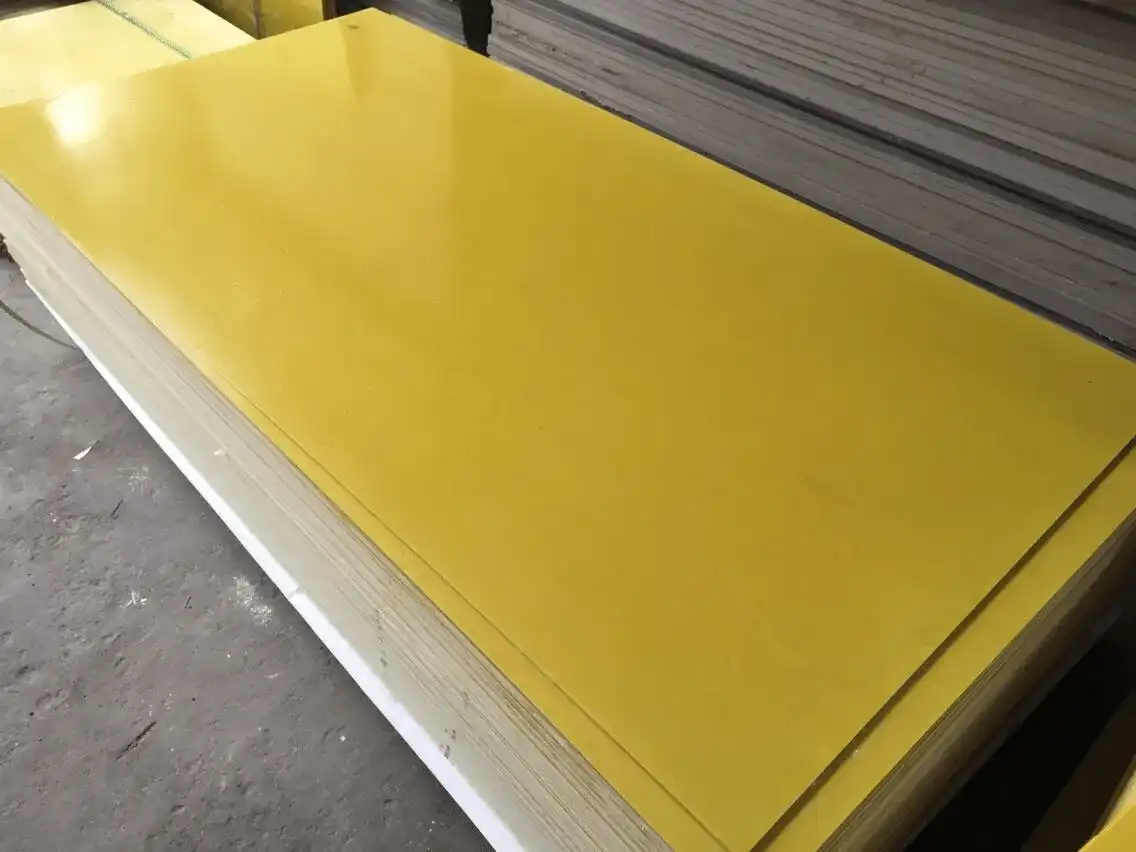

To choose the right epoxy sheet, you need to know about the different types of materials, their technical strengths, and the temperatures at which they can be used. In a wide range of industrial settings, these laminated composite materials provide excellent electrical insulation, chemical resistance, and structural stability. Knowing the performance characteristics of different epoxy resin formulations will help you choose the best material for your needs, whether you need FR4 fiberglass epoxy boards for electronics, high-temperature-resistant versions for power systems, or precision-machined parts for automotive use.

Understanding Epoxy Laminate Grades and Classifications

There are a few basic grades of industrial epoxy laminates, and each one is made to meet certain performance needs. The most commonly recognized classification system divides these materials based on resin chemistry, reinforcement type, and operating conditions.

Grade FR4 is the standard in the business for applications that need to be flame-resistant. This fiberglass epoxy composite is made of woven glass fabric and brominated epoxy resin. It has good electrical qualities and average mechanical strength. FR4 sheets are great for printed circuit board substrates and electrical enclosures because their dielectric properties stay fixed up to 130°C.

G10 grade products have the same kind of glass reinforcement, but they use regular epoxy resin that doesn't have any flame retardants in it. Compared to FR4, these sheets have better mechanical qualities and don't absorb as much water. G10 laminates are great for structural uses where flame protection isn't necessary but high strength-to-weight ratios are.

For better temperature protection, high-performance grades like G11 use silicone-modified epoxy systems. These high-tech composites keep their shape at temperatures up to 180°C, making them ideal for tough industrial and aircraft uses.

Even higher temperatures are possible with specialty types like FR5 and polyimide-based versions. These materials are used in specific situations where regular epoxy sheet systems would fail, like in power generation equipment and electronics that have to work in harsh environments.

Mechanical Strength Properties and Performance Metrics

There are several performance parameters that are used to judge mechanical strength and decide if it is right for a certain application. Tensile strength, which is a measure of how well a material resists pulling forces, is usually between 300 and 500 MPa for normal grades.

Flexural strength shows how well the laminate sheet resists bending forces. Flexural strengths of good epoxy laminates range from 400 to 600 MPa, based on how the fibers are arranged and the resin that is used. This trait is very important for structural parts that are loaded and unloaded quickly.

The amount of weight something can hold when it is crushed is based on its compressive strength. Industrial-grade materials can usually handle 350 to 450 MPa of compressive loads, which means they can be used as mechanical spacers and support structures in heavy machines.

Impact resistance is a material's ability to handle quick shock loads without breaking. Toughened resin systems are used in higher-grade laminates to make them better at handling impacts while keeping other good qualities.

Precision uses are affected by how stable dimensions are when they are loaded. Tough makers keep thickness tolerances (±0.1mm) and make sure that all production batches have the same mechanical properties. For automated assembly processes and precise machining, this level of uniformity is essential.

Long-term longevity under cyclic loading is based on fatigue resistance. Epoxy composites that are well-designed can keep 80% of their original strength after millions of load cycles. This is important for automotive and machinery uses that are stressed over and over again.

Temperature Resistance and Thermal Performance

The temperature range that epoxy-based insulation materials can work in determines their working envelope. In demanding situations, knowing both the constant working temperature and the short-term thermal spikes can help keep things from breaking down too soon.

Standard FR4 grades keep their structure solid up to 130°C constantly, and the temperatures at which they turn into glass are between 140°C and 150°C. When these limits are crossed, the resin starts to soften, which lowers its mechanical qualities and could cause it to lose its shape.

Continuous working temperatures can reach 170°C for high-temperature types like Tg170 materials. Advanced curing agents and resin modifiers are used in these special formulations to improve thermal performance while keeping electrical qualities the same.

In electronic applications, thermal conductivity changes how heat is lost. Standard epoxy sheets don't transfer heat very well (0.3–0.4 W/mK), which can be good for electrical insulation but should be thought about in designs that need to be resistant to heat.

The coefficient of thermal expansion affects how stable the dimensions are over a wide range of temperatures. Good materials keep their low expansion rates (12–16 ppm/°C) so that fixed parts don't have to deal with too much stress during thermal cycling.

The ability to withstand sudden changes in temperature is called thermal shock resistance. In industrial settings, materials are often heated or cooled quickly, which can cause internal stresses and the possibility of delamination.

Application-Specific Selection Criteria

When choosing epoxy insulation sheets, different businesses put different values on different material properties. Electronics makers put a lot of emphasis on dielectric strength and flame resistance, while machinery builders put a lot of emphasis on mechanical sturdiness and the ability to be machined.

For PCB uses, materials must meet IPC-4101 standards for electrical performance and stability in size. Key factors include the dielectric constant, which is usually between 4.2 and 4.8 ohms-cm at 1MHz, the dissipation factor being less than 0.02, and the volume resistance being more than 10^14 ohms-cm.

To keep electrical problems from happening, applications in the power business need high arc resistance and tracking resistance. The materials need to pass the ASTM D495 arc resistance tests and keep their insulation qualities when they are under a lot of voltage stress.

More and more, materials used in cars need to meet strict flammability standards, such as the UL94 V-0 grade. In addition, these parts must not break down when they are exposed to vibration, changing temperatures, and vehicle fluids.

Wear resistance and accurate measurements are important for industrial machinery uses. CNC machinability is very important for making precise parts with tight tolerances and smooth surfaces.

Quality Standards and Certification Requirements

Following industry norms makes sure that products are reliable and that they are accepted by regulators around the world. Knowing what certifications are needed helps buyers choose the right products for their needs.

For North American markets, UL recognition verifies flame protection and gives electrical safety approval. UL94 ratings for flammability put materials into groups from HB (horizontal burn) to V-0 (highest flame protection). Most electronics need V-1 or higher.

Following ROHS rules limits the use of dangerous materials in electronics, mainly lead, mercury, and some brominated chemicals. To meet these environmental needs, modern epoxy sheet recipes use different flame retardants that don't hurt performance.

International electrical component specs are set by IEC standards, which make sure that everything works together and is safe. IEC 61249 talks about PCB base materials and how they need to be tested in particular.

Specifications from the military, like MIL-I-24768 outline the performance needs for defense uses, such as the ability to withstand higher temperatures, higher humidity, and mechanical shocks.

ISO 9001 certification means that a company has quality control systems in place that make sure the quality of their products stays consistent and can be tracked. Suppliers who keep these certifications show that they are dedicated to quality control and growth all the time.

Processing and Machining Considerations

For epoxy laminates to be properly installed, they often need to go through additional processing steps. Understanding the limits and features of machining helps improve the quality and efficiency of manufacturing.

The factors for CNC machining are very different for different grades and thicknesses. The roughness of the glass support and the heat buildup during processing must be taken into account when choosing cutting speeds, feed rates, and tools.

Because of the glass fiber content, drilling activities need extra care. Controlled feed rates and sharp, specialized drill bits keep the holes clean for electrical assembly and stop delamination.

Edge sealing might be needed in some situations to keep water from getting into the exposed glass threads. The right sealers or conformal coatings keep the electrical properties of cut edges while protecting them.

During production, thermal processing must stay within the temperature limits of the material. Careful thermal control is needed to keep materials from breaking down during soldering, curing adhesives, and other high-temperature processes.

The way a surface is prepared affects how well it sticks during secondary bonding processes. Cleaning and treating the surface correctly is important for making sure that the bonds between parts of a building are strong.

Conclusion

To choose the right epoxy sheet, you have to weigh a number of performance factors against the needs of the product. Knowing the different types of materials, their strengths, and the highest and lowest temperatures that they can withstand lets you make smart choices that improve the performance of a part while keeping costs low. Suppliers of good quality, like J&Q, have the technical know-how and consistent production methods to meet the needs of demanding uses in the automotive, power, industrial, and electronics markets. Selecting the right materials and working with dependable suppliers are important for the long-term success of a project and the dependability of its parts in today's competitive production world.

Partner with J&Q for Premium Epoxy Sheet Solutions

Picking the right epoxy sheet supplier has a direct effect on the success of the job and the long-term dependability of the parts. J&Q has been making things for over 20 years and offers full technical support to make sure they give materials that exactly meet your needs.

We have a lot of experience with electronics for cars, power distribution systems, and uses for precision machinery. Because we know so much about the business, we can suggest the best material grades and processing methods for your specific needs. Quality control methods make sure that performance is the same from batch to batch and that prices stay low for large orders.

Technical consulting services help people make decisions about choosing materials that are hard to understand. Our engineering team gives you detailed advice based on real-world application knowledge, whether you need help with temperature ratings, electrical properties, or mechanical performance criteria.

Full testing options make sure that the qualities of the material are correct and that it meets all the standards that apply. Electrical, mechanical, and thermal tests are done in-house in labs to make sure that performance standards are met before the goods are shipped.

Through our integrated supply chain management, our global logistics skills make sure that delivery dates are kept. Because we have our own logistics business, we can provide one-stop service from choosing the materials to delivering them, which makes the buying process easier for customers from other countries.

Are you ready to talk about your epoxy sheet needs? Our technical team is ready to help you find the best options for your application. Get in touch with us at info@jhd-material.com to talk to experienced materials experts who know how to find the right balance between performance, cost, and delivery needs for successful product creation.

References

Harper, Charles A. "Handbook of Plastics, Elastomers, and Composites." 4th Edition. McGraw-Hill Professional, 2002.

Lubin, George. "Handbook of Composites." Van Nostrand Reinhold Company, 1982.

Lee, Henry and Kris Neville. "Handbook of Epoxy Resins." McGraw-Hill Book Company, 1967.

Pascault, Jean-Pierre and Roberto J.J. Williams. "Epoxy Polymers: New Materials and Innovations." Wiley-VCH, 2010.

Ellis, Bryan. "Chemistry and Technology of Epoxy Resins." Blackie Academic & Professional, 1993.

May, Clayton A. "Epoxy Resins: Chemistry and Technology." 2nd Edition. Marcel Dekker Inc., 1988.