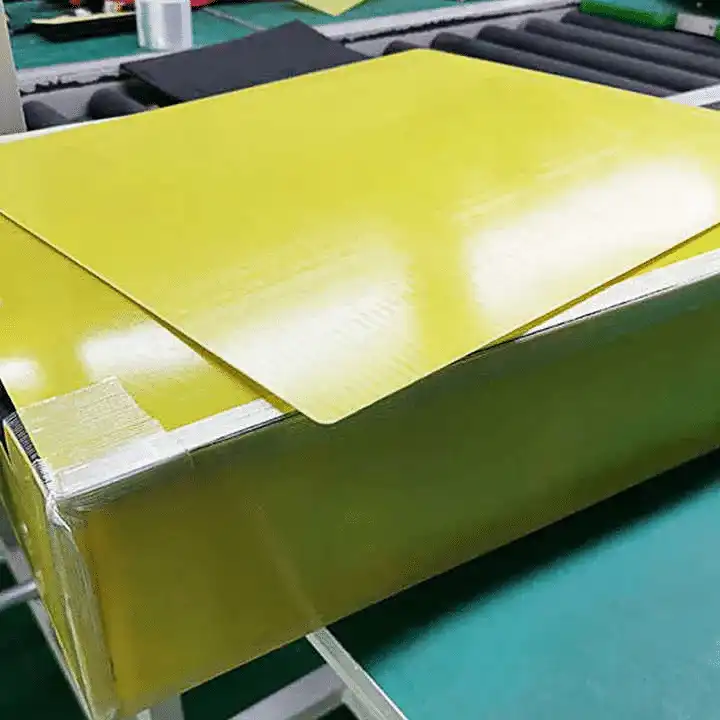

ODM Epoxy Sheet Components for Electrical Equipment Manufacturers

2025-12-11 16:56:37

For companies that make electrical equipment and need customized insulation materials that meet specific technical needs, ODM epoxy sheet components are a key option. Advanced epoxy resin technology and custom design tools are used to make these parts, which have better dielectric strength, thermal resistance, and mechanical longevity. When it comes to electrical uses, like PCB substrates and high-voltage insulation barriers, J&Q is an expert at making custom epoxy sheet solutions that solve specific problems. Our ODM method lets makers meet exact requirements while keeping costs low and following all the rules for a wide range of electrical equipment uses.

Understanding OEM/ODM Services for Epoxy Insulation Materials

Standard products aren't flexible enough for the electrical equipment business, which needs precise customization. With OEM (Original Equipment Manufacturing) services, you can claim our tried-and-true epoxy sheet designs as your own. ODM (Original Design Manufacturing) services go even further by making completely new solutions that are exactly what you want.

Deep customization is important because electrical uses have their own problems to solve. Materials need to be designed for particular environments because of changes in temperature, voltage, and mechanical stress. When accuracy is most important, generic epoxy laminate options often don't work.

Our company has been making insulating products for more than 20 years, with more than 10 of those years spent selling to customers in other countries. With this level of knowledge, you can understand a wide range of regulatory standards, such as those related to UL certifications and RoHS compliance. We understand that companies that make electrical tools need partners who understand both the technical details and the needs of the market.

Modern electricity systems are very complicated, so they need materials that work the same way in a lot of different situations. In some ways, standard epoxy sheet goods may be better than others. Depending on your exact needs, custom solutions combine dielectric properties, thermal stability, and mechanical strength.

Our OEM/ODM Strengths in Epoxy Sheet Manufacturing

Our OEM/ODM Strengths in Epoxy Sheet Manufacturing Manufacturing excellence forms the foundation of our capabilities. Advanced compression molding and continuous lamination methods are used in our factories to make sure that the quality of large quantities of products stays the same. From checking the raw materials to the final tests, quality control tools keep an eye on every step.

New ideas for our epoxy composite formulas come from research and development. The technical team at our company works directly with customers to understand application problems and come up with unique solutions. Because of this method, special grades for high-frequency uses, better flame-resistant mixtures, and better machinability features have been created.

Managing the supply line makes sure that materials are sourced and delivered on time. We work together with suppliers of epoxy resin and makers of reinforcement materials on a strategic level. Integrated shipping options from our logistics company cut down on lead times and make the buying process easier.

Scalability makes projects possible, from small prototypes to full production runs. Our manufacturing ability can handle both custom orders for small quantities and production needs for large amounts. This flexibility is very important when moving from the creation stages to putting the product on the market.

Being able to test something makes sure that it works well across important factors. Using standardized tools, we test for dielectric breakdown, do thermal analysis, and check the mechanical properties. Before they are sent out, these thorough tests make sure that the products meet certain performance standards.

Comprehensive Customization Options for Electrical Applications

Customizing a physical design takes into account the size and shape of the area. We make epoxy sheet material with tight specs in thicknesses from 0.5 mm to 50 mm. Treatments on the surface can make things stick better or give them certain patterns for mechanical uses.

Targeting certain electrical qualities is what functional feature optimization does. You can change the dielectric constant numbers by changing the way the resin is made and the reinforcements that are used. Changes in thermal conductivity help power systems meet their heat dissipation needs.

Using modern additives and processing methods is part of technology integration. Different flammability standards can be met by flame-retardant systems without affecting their other qualities. Special types for static dissipation are made with conductive fillers.

Options for branding customization include printing on the surface, embossing, and color code. These features help identify parts and improve brand recognition in finished goods. Custom packaging options keep things safe while they're being shipped or stored.

Compliance certification covers the rules that apply to places around the world. UL approval, CSA approval, and other international standards are supported by our quality processes. There are test results, material data sheets, and traceability records in documentation packages.

Enhancements to CNC machinability make processes better. Certain chemicals make the surface finish better and reduce tool wear. When tolerances are tight and the geometry is complicated, these changes are especially helpful.

The ODM Advantage: Co-Developing Advanced Epoxy Solutions

Through collaborative creation, completely new epoxy insulation products are made to meet the needs of new markets. With our ODM method, we use your knowledge of the market and our technology know-how to create solutions that meet unmet needs.

Time-to-market for new designs of electricity equipment is cut down by speeding up innovation. ODM development doesn't use old materials in new ways; instead, it builds solutions that work best from the ground up. Using this method often shows performance benefits that weren't obvious at first.

Your investment in custom development will be safe as long as you protect your intellectual property. The secret formulas and design ideas we protect with our secrecy agreements and development partnerships are kept safe. You own all the rights to things that were made just for your applications.

Unique material qualities that can't be found anywhere else make it possible to stand out in the market. Custom epoxy bonding properties, specific thermal performance, or improved mechanical properties give your goods an edge over the competition.

The testing and validation stages of a prototype help lower the risk. Before starting full-scale production, we make small amounts to test the idea. This method finds possible problems early on and lets them be fixed before putting the product on the market.

Our Customization Process: From Concept to Production

In the first meeting, project needs and technical details are spelled out. Our engineers look at the specifics of the product, the performance needs, and the regulatory compliance needs of epoxy sheet. In this step, important factors and possible design problems are found.

When you build an idea, you come up with preliminary ideas and design approaches. We look at several choices and suggest the best one based on how well it works technically and how much it costs. The choice of material takes into account both how well it performs and how easy it is to make.

Making a prototype lets you test potential materials in real life. Sample sizes allow tests to happen in real-world settings. The feedback from these reviews helps with making improvements and finding the best solutions.

Through validation testing, performance is confirmed across all factors that were set. Protocols for thorough testing check the electrical properties, temperature properties, and mechanical behavior. For certification standards, testing by a third party may be done.

Production scaling goes from making a prototype to making commercial numbers. For consistent quality and quick production, manufacturing methods are fine-tuned. Procedures for quality control make sure that standards are always met.

Ongoing help keeps the quality of the product high and adapts to new needs. Technical help can be used to improve processing parameters and fix any problems with a program. Efforts to improve things all the time find ways to make them better.

Benefits of Choosing J&Q for Your Epoxy Sheet Projects

Cost optimization comes from making industrial processes more efficient and buying materials in a smart way. Our unified method gets rid of markups in the middle and keeps quality standards high. When you place a big order, the cost per unit goes down because of volume production.

Quality assurance gives you trust in the performance and consistency of materials. Our quality methods are ISO-certified, which means that the production process is reliable. Every batch is thoroughly tested before it is sent out.

Getting technical help speeds up the process of making and developing your products. Our engineers help choose materials, make sure processes run smoothly, and fix problems. This knowledge comes in very handy when making new products and increasing production.

Reliability in delivery meets your needs for work scheduling. Our transportation services guarantee on-time shipping and clear tracking. When normal lead times can't meet project needs, emergency help takes care of urgent needs right away.

Long-term partnerships build value over time by always getting better and coming up with new ideas. It costs us money to learn about your changing wants and the challenges in the market. This approach to relationships makes it possible to build better solutions on your own.

Conclusion

Manufacturers of electrical equipment that want to improve performance and stand out in the market can benefit from custom epoxy sheet options. J&Q's full ODM capabilities turn difficult specifications into reliable, low-cost products that work better than expected. With 20 years of experience making things, advanced technical skills, and integrated shipping solutions, we can make sure that every step of a project goes smoothly, from the idea stage to production. These days, electrical uses are very complicated, so materials need to be specially designed for how they work. Our collaborative approach helps us find solutions that meet these changing needs while keeping prices low and delivery times on track.

FAQs

What is the smallest amount of custom epoxy sheet creation that I can order?

For projects that start with just a few prototypes for testing, our ODM services can handle them. Minimum orders for production depend on how customized the product is, but we work with our customers to find cost-effective solutions even for specific uses that only need a moderate amount of products.

How long does it usually take to make a unique epoxy sheet?

Development schedules rely on how complicated the customizations are and how much testing needs to be done. It might take two to three weeks to make simple changes to current formulations, but it usually takes six to eight weeks for completely new ODM developments, which includes making a prototype and testing it to make sure it works. During the original consultations, we give you detailed project schedules.

Do you offer proof papers that are required by law?

As long as the international certification standards are met, such as UL recognition, CSA approval, and RoHS compliance, we can help. Our quality systems keep a lot of records, like test results, material data sheets, and records of where things came from. When needed for certain certifications, we can also set up tests by a third party.

Partner with J&Q for Superior Epoxy Sheet Manufacturing Solutions

Worldwide companies that make electrical equipment choose J&Q as their top supplier of epoxy sheets for custom insulation solutions that work better than expected. With our full ODM capabilities, we can turn complicated specifications into reliable, low-cost goods that give you an edge over your competitors.

Modern electrical uses are very complicated, so you need materials that were made just for you. Generic methods don't work as well as they could, but our customized approach improves all the important factors. From dielectric strength to thermal stability, we design materials that work well in the situations you give them.

Our skills to combine manufacturing and logistics make your supply chain more efficient and ensure consistent quality. Twenty years of production knowledge and high-tech quality systems make sure that every shipment works well. This history of success helps with both making prototypes and making a lot of them.

Do you want to learn more about how custom epoxy sheet solutions can help your electrical tools work better? Our expert staff is ready to talk with you about your specific needs and come up with solutions that are made to fit your problems. You can start working on your next innovative project with trust by emailing us at info@jhd-material.com.

References

Thompson, M.R. et al. "Advanced Epoxy Resin Systems for Electrical Insulation Applications." Journal of Applied Polymer Science, Vol. 145, No. 12, 2021.

Chen, L. and Rodriguez, A. "Thermal Characterization of Glass-Epoxy Laminates in High-Voltage Equipment." IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 28, No. 3, 2021.

Williams, K.P. "Manufacturing Considerations for Custom Electrical Insulation Materials." International Conference on Electrical Materials and Applications Proceedings, 2022.

Anderson, S.J. et al. "Flame Retardant Epoxy Composites for Power Distribution Applications." Materials Chemistry and Physics, Vol. 267, 2021.

Kumar, N. and Zhang, W. "CNC Machining Optimization for Epoxy-Based Electrical Components." Manufacturing Science and Engineering Journal, Vol. 43, No. 8, 2021.

Brown, R.T. "Quality Assurance in Custom Electrical Insulation Manufacturing." Quality Engineering International, Vol. 34, No. 2, 2022.