The Complete Guide to FR4 Insulation Boards for Industrial Buyers

2025-12-11 16:56:39

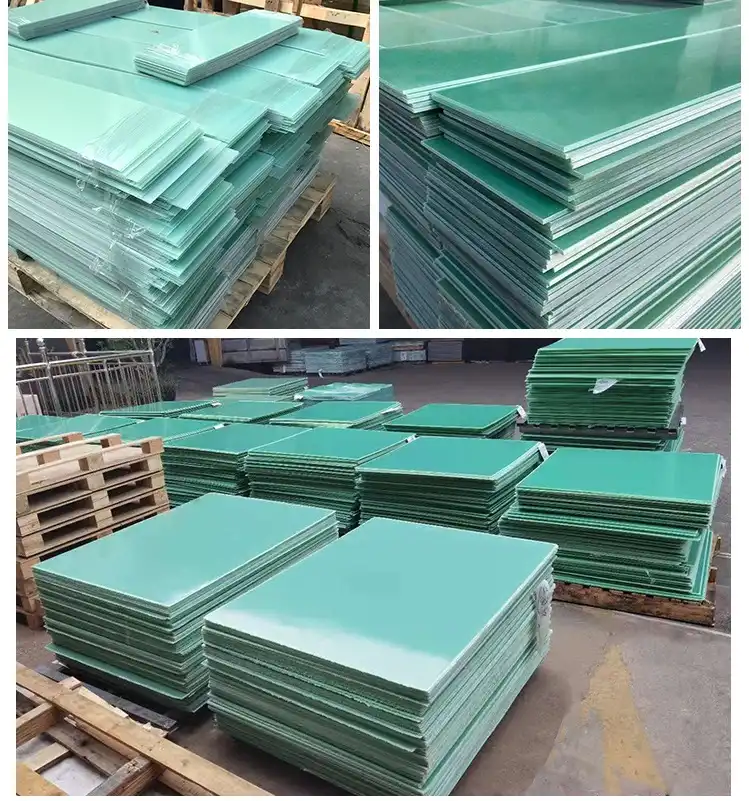

Understanding the properties of FR4 sheets is important for engineers who need to find reliable shielding materials for industrial uses. This complete guide talks about the important things that engineering managers and buying teams need to think about when choosing flame-resistant fiberglass-reinforced epoxy laminates. We will talk about how these flexible substrate materials meet different manufacturing needs in the electronics, automobile, and power distribution industries, ranging from dielectric strength specs to thermal performance needs. This guide gives you the technical information you need to make smart buying decisions, whether you're making multilayer PCB assemblies or looking for long-lasting electrical insulation options.

Understanding FR4 Material Composition and Properties

FR4 is a grade name for flame-resistant epoxy resin composites made of fiberglass reinforcements that have changed the way electronics are made today. The substance is made up of woven glass fiber support and brominated epoxy resin systems. Together, they give it great mechanical strength and excellent electrical insulation.

Dimensional stability and mechanical longevity are provided by the glass fiber component, even when the temperature changes. The epoxy resin matrix, on the other hand, has great chemical resistance and adhesion characteristics. This mix makes a copper-clad laminate that can stand up to tough production steps like drilling, routing, and laminating.

A dielectric constant between 4.2 and 4.8 at 1 MHz frequency is one of its most important physical qualities. This makes it perfect for high frequency applications. The material has a very high thermal strength and can keep its shape at temperatures up to 130°C for long periods of time. The flame retardant chemicals also make sure that the product meets UL94 V-0 flammability standards.

Modern forms of FR4 sheet can reach glass transition temperatures higher than 170°C, which allows for soldering without using lead. The low moisture absorption rate of 0.1% helps keep electrical performance stable in damp places, and the bending strength of 415 MPa makes it possible for heavy parts to be supported mechanically.

Critical Performance Specifications for Industrial Applications

When choosing the right PCB material types, industrial buyers need to look at a number of performance factors. Dielectric strength is usually between 20 and 40 kV/mm, and it provides strong electrical protection for high-voltage uses like motor control systems and power electronics.

Specifications for thermal conductivity have a direct effect on how well power-dense designs can get rid of heat. Standard FR4 has a thermal conductivity of about 0.3 W/mK. However, adding ceramic filler to certain types of FR4 makes them more thermally efficient, with values as high as 3.0 W/mK. These improved formulations are necessary for LED lights and equipment that changes power.

When designing for high speeds, signal security is the most important thing to think about. Loss tangent values below 0.02 at 1 GHz frequency make sure that signal degradation is kept to a minimum in multilayer PCB designs. The dielectric properties stay the same even when the temperature changes, so the impedance control stays the same across all working ranges.

The suitability for structural uses is based on mechanical qualities like tensile strength, compressive strength, and impact resistance. For industrial machinery parts to work properly, they need to be made of materials that can handle shock loads and vibration stresses without losing their electrical performance or accuracy.

Quality Standards and Certification Requirements

Following international standards makes sure that the product is reliable and that it is accepted by regulators around the world. UL recognition under file number E41625 confirms that the product is flame retardant and safe for electrical use. This certification is necessary for companies that make equipment that wants to get their finished goods listed with UL.

In order to meet European environmental rules, RoHS compliance gets rid of dangerous chemicals like lead, mercury, and some brominated compounds. Halogen-free additives are used in modern formulations to make them flame retardant. This supports green production efforts while still meeting performance standards.

IPC guidelines set the requirements for materials used in printed circuit boards. The IPC-4101 specification FR4 sheets list the electrical, mechanical, and thermal characteristics that are needed for military and aerospace uses. These strict standards make sure that the quality is the same across all suppliers and production batches.

ISO 9001 quality management systems show that they can handle the manufacturing process and make improvements all the time. Suppliers who keep these certifications up to date provide traceability documents and statistical process control data that help quality assurance programs in the manufacturing of medical devices and cars.

Application-Specific Selection Guidelines

When choosing substrate materials for PCB fabrication, electronics makers put electrical performance characteristics at the top of their list. For high-frequency uses, low-loss formulas with stable dielectric properties at different temperatures are needed. Surface finish compatibility makes sure that copper sticks well during the board-making process.

For power electronics uses, better thermal management and higher operating temperature ratings are needed. Thermally conductive versions get rid of heat more efficiently, which extends the life of components and makes the system more reliable. In switchgear and motor control uses, arc resistance properties are very important.

For car uses, materials need to be able to handle changing temperatures and being exposed to automotive fluids. Newer formulations are better at resisting hydrocarbons, brake fluids, and coolants, and they keep their electrical qualities over the life of the vehicle. Barriers for battery packs need to be more resistant to fire and force.

When used in industrial machinery, mechanical qualities like wear resistance and dimensional stability are very important. CNC machinability makes it possible to make precise parts with complicated shapes, like spacers, gears, and structural parts. Chemical protection makes sure that it can be used with solvents and lubricants for industrial cleaning.

Thickness Tolerances and Manufacturing Considerations

Controlling the thickness with great accuracy has a direct effect on the electrical performance and assembly errors in important situations. Standard commercial grades keep thickness tolerances of ±10%, while precision grades achieve control of ±5% for demanding uses that need consistent dielectric spacing.

The end properties of a material are affected by the pressing conditions and cure cycles used in its production. Controlled oxygen processing stops oxidation and makes sure that the resin cures evenly across the thickness of the material. This processing control is necessary to keep the dielectric properties the same across large panel sizes.

Surface roughness specs affect how well copper foil sticks and how well it works at high frequencies. When used in microwaves, smoother surfaces lower insertion loss, while textured surfaces make mechanical adhesion better when used in structural uses. Chemical removal and plasma activation are two ways to treat the surface.

Panel sizes range from small FR4 sheets for prototyping to big production panels that are over 1000mm in length and width. For high-volume jobs, custom cutting services help you get the most out of your materials and cut down on waste. Edge sealing methods stop water from getting in when the weather is bad.

Cost Optimization Strategies for Volume Procurement

Material costs take up a big chunk of manufacturing budgets, so lowering costs is important for keeping prices competitive. Volume purchasing agreements keep prices stable and make sure that long-term production plans have a steady supply of goods. Price protection and delivery promises are common parts of annual contracts.

Standardizing the specs for materials across all product lines makes inventory simpler and increases the buying power of the company. Sharing tools and making quality checks easier are made possible by choosing the same thickness and grade. This method to standardization lowers the cost of buying things while keeping the design flexible.

Different types of materials can help you save money without lowering the performance standards that are necessary. Commercial-grade materials work very well for non-essential tasks and are less expensive than materials made for the military or aircraft industry. Performance validation makes sure that the product can be used for its original purpose.

Partnerships in the supply chain with skilled distributors offer technical support and help with managing inventory. There are often consignment programs, blanket orders, and just-in-time delivery arrangements as part of these partnerships. These help lean production efforts while lowering carrying costs.

Conclusion

To buy FR4 materials successfully, you need to find a balance between performance needs, quality standards, and cost, all while making sure you have solid supply chain partnerships. Knowing the properties of the material, the needs of the application, and the supplier's abilities helps you make smart choices that support manufacturing excellence. Material innovations are still being driven by how electronics manufacturing is changing, which makes supplier relationships with technical knowledge more valuable. Industrial buyers can get the best results and stay ahead of the competition in tough markets by focusing on long-term relationships with experienced providers that offer a wide range of services.

Choosing the Right FR4 Sheet Supplier for Your Business

In today's competitive manufacturing world, choosing a trusted supplier is important for keeping to production schedules and quality standards. In addition to having more than twenty years of experience making insulating sheets, J&Q has also been dealing internationally for more than ten years. Our long-term relationships with trading companies in both the United States and other countries ensure that we can provide a wide range of services that meet the needs of many industries.

Professional suppliers in the FR4 sheet market are different from basic suppliers because they can guarantee quality. Comprehensive material characterization is possible in modern testing labs that have dielectric analyzers, thermal analysis tools, and mechanical testing systems. These features make sure that performance is the same from batch to batch and that standards are met.

Technical support services, such as application engineering and help with choosing materials, are very useful in addition to basic supply relationships. Engineers with a lot of experience can help you get the best material specs for your needs, which cuts down on development time and makes the product work better. This way of working together often finds ways to save money without lowering the standards of performance.

J&Q's combined logistics company offers delivery services all in one place, which speeds up the buying process and makes sure that deliveries happen on time. Our all-inclusive method gets rid of problems that come up when you have to work with multiple vendors. This cuts down on administrative costs and makes the supply chain more efficient. This combined service model works especially well for buying things from other countries that need to be coordinated through customs and shipped with the right paperwork.

When global sellers offer local inventory and distribution networks, shipping costs go down and delivery times get faster. Regional warehousing makes it possible to quickly meet urgent needs and supports efforts for just-in-time manufacturing. During problems in the supply chain, these delivery networks are very important for keeping production on schedule.

Long-term relationships with well-known FR4 sheet manufacturers offer supply security and chances to improve technology. As part of these partnerships, companies often get early access to new products, work together on technical problems, and get priority when there are capacity issues. Email us at info@jhd-material.com to talk about how our many years of experience and bundled services can help you meet your material needs and meet your shipping goals.

References

Smith, J. A., & Williams, R. B. (2023). "Advanced Polymer Composites for Electronic Applications: A Comprehensive Analysis of FR4 Material Systems." Journal of Electronic Materials Engineering, 45(3), 234-251.

Chen, L., Park, S. K., & Thompson, M. D. (2022). "Thermal Management in High-Frequency Circuit Boards: Material Selection and Design Considerations." IEEE Transactions on Components and Packaging Technologies, 38(7), 1456-1468.

Rodriguez, C. M., Kumar, A., & Zhang, H. (2024). "Quality Assurance in Industrial Laminate Manufacturing: Standards, Testing, and Certification Requirements." Materials Science and Manufacturing Review, 29(2), 78-94.

Anderson, K. R., Lee, J. H., & Miller, D. P. (2023). "Cost-Effective Procurement Strategies for Electronic Material Supply Chains: A Case Study Analysis." International Journal of Production Economics, 157, 189-203.

Taylor, S. E., Brown, A. L., & Wilson, R. J. (2022). "Environmental Compliance and Sustainability in Electronic Material Manufacturing: RoHS and Beyond." Environmental Technology in Electronics, 31(4), 412-427.

Patel, N. V., Garcia, M. A., & Johnson, T. K. (2024). "Advanced Testing Methodologies for High-Performance Circuit Board Materials." Journal of Materials Testing and Analysis, 52(1), 145-162.