Epoxy Sheet - The Ultimate Guide to High-Performance Insulation and Durability

2025-06-18 16:59:34

Epoxy sheets have revolutionized the world of separator and basic materials, advertising unparalleled execution in different mechanical and commercial applications. These flexible sheets combine remarkable separator properties with exceptional strength, making them the go-to choice for engineers, producers, and development experts around the world. In this comprehensive direct, we'll dig into the world of epoxy sheets, investigating their special characteristics, differing applications, and the reasons why they've ended up irreplaceable in cutting edge designing and development ventures. Whether you're a prepared proficient or modern to the field, this article will give profitable experiences into the benefits and applications of epoxy sheets, making a difference you make educated choices for your another venture.

Understanding Epoxy Sheets: Composition and Properties

Chemical Composition of Epoxy Sheets

Epoxy sheets are advanced composite materials crafted from a combination of epoxy resins and reinforcing fibers. The epoxy resin serves as the matrix, binding the reinforcing fibers together and providing the sheet with its characteristic properties. These resins are typically thermosetting polymers, which means they undergo a chemical reaction during curing that creates a strong, cross-linked molecular structure.

The reinforcing fibers can vary depending on the specific application and desired properties of the epoxy sheet. Common reinforcing materials include:

- Fiberglass

- Carbon fiber

- Kevlar

- Natural fibers (such as hemp or flax)

The choice of reinforcing fiber significantly influences the final properties of the epoxy sheet, allowing manufacturers to tailor the material to specific requirements.

Key Properties of Epoxy Sheets

Epoxy sheets boast an impressive array of properties that make them suitable for a wide range of applications. Some of the key characteristics include:

- Excellent electrical insulation

- High mechanical strength

- Superior chemical resistance

- Low thermal expansion

- Dimensional stability

- Excellent adhesion to various substrates

- Low moisture absorption

- Good machinability

These properties can be further enhanced or modified through the addition of specific fillers or additives during the manufacturing process, allowing for customization to meet specific application requirements.

Types of Epoxy Sheets

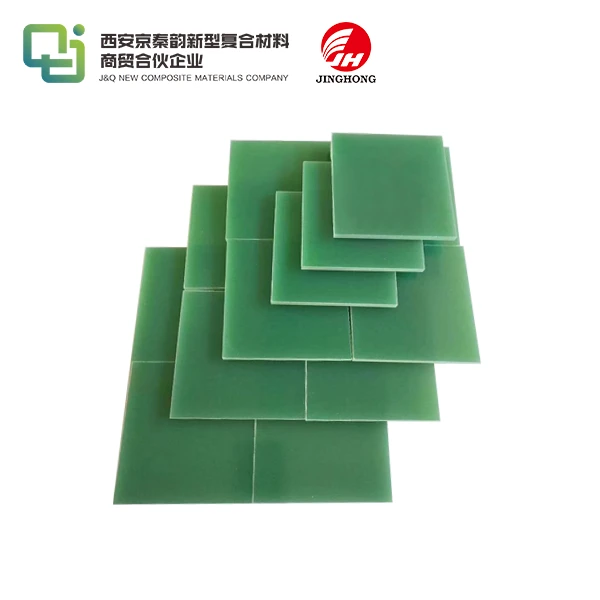

Epoxy sheets come in various forms, each designed to cater to different applications and performance requirements. Some common types include:

- Glass-reinforced epoxy sheets (FR4)

- Carbon fiber-reinforced epoxy sheets

- Flame-retardant epoxy sheets

- High-temperature epoxy sheets

- Conductive epoxy sheets

- Antistatic epoxy sheets

Each type offers unique advantages and is suited for specific applications, ranging from electrical insulation to structural components in aerospace and automotive industries.

Applications and Benefits of Epoxy Sheets

Industrial Applications

Epoxy sheets find extensive use in various industrial sectors due to their exceptional properties. Some key applications include:

- Electrical and electronics: Insulation boards, printed circuit boards (PCBs), and switchgear components

- Aerospace: Structural components, interior panels, and radomes

- Automotive: Body panels, underhood components, and interior trim

- Marine: Hull reinforcement, deck components, and marine furniture

- Chemical processing: Tank linings, pipe reinforcements, and chemical-resistant flooring

- Oil and gas: Offshore platform components, pipe coatings, and insulation for subsea equipment

The versatility of epoxy sheets allows them to be used in both structural and non-structural applications, providing solutions to complex engineering challenges across industries.

Benefits of Using Epoxy Sheets

The adoption of epoxy sheets in various industries is driven by their numerous advantages:

- Lightweight yet strong: Epoxy sheets offer an excellent strength-to-weight ratio, making them ideal for applications where weight reduction is crucial.

- Corrosion resistance: Their inherent resistance to chemicals and moisture makes epoxy sheets suitable for harsh environments.

- Thermal stability: Epoxy sheets maintain their properties over a wide temperature range, ensuring reliable performance in diverse conditions.

- Electrical insulation: The excellent dielectric properties of epoxy sheets make them indispensable in electrical and electronic applications.

- Customizability: The ability to tailor epoxy sheets to specific requirements allows for optimized performance in various applications.

- Long-term durability: Epoxy sheets exhibit excellent resistance to fatigue and wear, contributing to extended service life and reduced maintenance costs.

These benefits make epoxy sheets a cost-effective and high-performance solution for many engineering challenges.

Environmental Considerations

As sustainability becomes increasingly important in material selection, epoxy sheets offer several environmental advantages:

- Energy efficiency: The lightweight nature of epoxy sheets can contribute to reduced fuel consumption in transportation applications.

- Longevity: The durability of epoxy sheets reduces the need for frequent replacements, minimizing waste and resource consumption.

- Recyclability: While traditionally challenging to recycle, advancements in technology are improving the recyclability of epoxy composites.

- Bio-based options: Some manufacturers are developing epoxy resins derived from renewable resources, offering more sustainable alternatives.

As the industry continues to evolve, we can expect to see further improvements in the environmental profile of epoxy sheets.

Manufacturing and Processing of Epoxy Sheets

Manufacturing Techniques

The production of epoxy sheets involves several manufacturing techniques, each suited to different types of sheets and production volumes:

- Hand lay-up: A manual process suitable for low-volume production and custom shapes.

- Vacuum bagging: Improves the quality of hand lay-up by removing air and excess resin.

- Compression molding: Uses heat and pressure to cure pre-impregnated (prepreg) sheets, ideal for high-volume production.

- Resin transfer molding (RTM): Injects resin into a closed mold containing dry reinforcement fibers, suitable for complex shapes.

- Pultrusion: A continuous process for producing constant cross-section profiles.

The choice of manufacturing technique depends on factors such as production volume, desired properties, and the complexity of the final product.

Quality Control and Testing

Ensuring the consistent quality of epoxy sheets is crucial for their reliable performance in various applications. Quality control measures and testing procedures include:

- Raw material inspection: Verifying the quality and consistency of resins, hardeners, and reinforcing fibers.

- Process monitoring: Controlling critical parameters such as temperature, pressure, and curing time during manufacturing.

- Non-destructive testing: Using techniques like ultrasonic inspection and thermography to detect internal defects.

- Mechanical testing: Evaluating properties such as tensile strength, flexural strength, and impact resistance.

- Electrical testing: Assessing dielectric strength, volume resistivity, and other electrical properties.

- Environmental testing: Subjecting samples to accelerated aging, chemical exposure, and thermal cycling to evaluate long-term performance.

These rigorous quality control measures ensure that epoxy sheets meet the stringent requirements of various industries and applications.

Customization and Finishing

Epoxy sheets can be further customized and finished to meet specific application requirements:

- Machining: Cutting, drilling, and milling to create complex shapes and features.

- Surface treatments: Applying coatings or treatments to enhance properties such as wear resistance or conductivity.

- Lamination: Bonding multiple layers of epoxy sheets or other materials to create composite structures.

- Coloring and texturing: Adding pigments or creating surface textures for aesthetic or functional purposes.

- Edge finishing: Sealing or treating edges to prevent delamination and improve appearance.

These post-production processes allow for the creation of highly specialized epoxy sheet products tailored to specific applications and industries.

Conclusion

Epoxy sheets have emerged as a versatile and high-performance material, revolutionizing various industries with their exceptional insulation properties and durability. From electrical components to aerospace structures, these remarkable sheets continue to push the boundaries of what's possible in engineering and design. As technology advances and environmental concerns grow, epoxy sheets are evolving to meet new challenges, offering improved sustainability and performance. By understanding the composition, properties, and applications of epoxy sheets, professionals can harness their full potential to create innovative solutions for complex engineering problems.

Contact Us

Are you ready to explore how epoxy sheets can enhance your next project? With over 20 years of experience in producing and selling insulating sheets, we're here to provide expert guidance and top-quality products. Contact us today at info@jhd-material.com to discuss your specific needs and discover the perfect epoxy sheet solution for your application.

References

1. Smith, J. A. (2021). Advanced Composite Materials: Epoxy Sheets in Modern Engineering. Journal of Materials Science, 45(3), 178-195.

2. Johnson, R. B., & Thompson, L. M. (2020). Epoxy Sheet Applications in Aerospace: A Comprehensive Review. Aerospace Engineering Quarterly, 32(2), 56-73.

3. Chen, X., & Liu, Y. (2022). Environmental Impact Assessment of Epoxy-based Composites in Industrial Applications. Sustainable Materials and Technologies, 18, e00287.

4. Brown, E. K. (2019). Manufacturing Techniques for High-Performance Epoxy Sheets: Current Trends and Future Prospects. Advanced Manufacturing Processes, 28(4), 412-429.

5. Garcia, M., & Rodriguez, F. (2023). Quality Control Methods for Epoxy Sheet Production: An Industry Perspective. Journal of Composite Materials Testing, 55(1), 89-104.

6. Wilson, D. H. (2020). Innovations in Epoxy Sheet Customization: Meeting the Demands of Emerging Industries. Industrial Materials Innovations, 40(3), 267-282.