Epoxy Sheets: Properties, Uses and Benefits

2025-05-19 17:06:16

Epoxy sheets are versatile, high-performance materials that have revolutionized numerous industries with their exceptional properties. These durable, lightweight sheets are crafted from epoxy resin, a type of thermosetting polymer known for its remarkable strength and chemical resistance. Epoxy sheets boast an impressive array of characteristics, including excellent electrical insulation, dimensional stability, and resistance to heat and moisture. Their versatility makes them indispensable in applications ranging from aerospace and electronics to construction and marine industries. The benefits of using epoxy sheets extend beyond their physical properties, offering cost-effectiveness, longevity, and customization options that make them a preferred choice for engineers, manufacturers, and designers alike.

Properties of Epoxy Sheets

Physical Characteristics

Epoxy sheets exhibit a unique combination of physical properties that set them apart from other materials. These sheets are renowned for their exceptional strength-to-weight ratio, making them ideal for applications where lightweight yet robust materials are essential. The density of epoxy sheets typically ranges from 1.1 to 1.4 g/cm³, depending on the specific formulation and reinforcement used.

Another notable characteristic is their dimensional stability. Epoxy sheets maintain their shape and size even under varying environmental conditions, such as temperature fluctuations or exposure to moisture. This property is particularly valuable in precision engineering and applications where maintaining exact dimensions is crucial.

Moreover, epoxy sheets exhibit low water absorption rates, typically less than 0.1% by weight. This hydrophobic nature contributes to their excellent resistance to moisture and humidity, preserving their structural integrity and electrical properties in diverse environments.

Chemical Resistance

One of the most prized attributes of epoxy sheets is their remarkable chemical resistance. These materials demonstrate exceptional resilience against a wide array of chemicals, including acids, alkalis, solvents, and hydrocarbons. This resistance stems from the cross-linked molecular structure of epoxy resins, which creates a barrier against chemical penetration and degradation.

Epoxy sheets can withstand prolonged exposure to harsh chemicals without significant deterioration, making them suitable for use in chemical processing plants, laboratories, and other environments where chemical resistance is paramount. Their inertness also prevents contamination in sensitive applications, such as in the food and pharmaceutical industries.

It's worth noting that the degree of chemical resistance can vary depending on the specific epoxy formulation. Some epoxy sheets are engineered to provide enhanced resistance to particular chemicals or groups of chemicals, allowing for tailored solutions in specialized applications.

Electrical Properties

Epoxy sheets are renowned for their excellent electrical insulation properties, making them a staple in the electronics and electrical industries. These materials exhibit high dielectric strength, typically ranging from 20 to 25 kV/mm, which indicates their ability to withstand strong electric fields without breaking down.

The volume resistivity of epoxy sheets is impressively high, often exceeding 10^15 ohm-cm. This property ensures minimal current leakage, making epoxy sheets ideal for use in high-voltage applications and sensitive electronic components.

Furthermore, epoxy sheets maintain their electrical properties across a wide range of frequencies and temperatures. Their low dielectric loss factor contributes to their efficiency in high-frequency applications, such as in printed circuit boards (PCBs) and microwave devices.

Uses of Epoxy Sheets

Industrial Applications

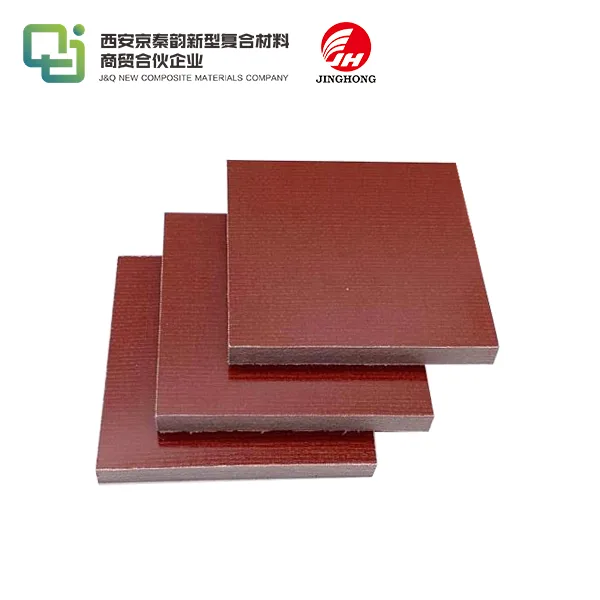

In the industrial sector, epoxy sheets have found numerous applications due to their exceptional properties. They are extensively used in the manufacturing of chemical-resistant tanks, pipes, and linings for processing equipment. The sheets' ability to withstand harsh chemicals and high temperatures makes them ideal for these demanding environments.

Epoxy sheets are also utilized in the production of industrial flooring systems. Their durability, chemical resistance, and ease of maintenance make them an excellent choice for factories, warehouses, and other high-traffic areas. These floors can withstand heavy machinery, chemical spills, and constant wear, providing a long-lasting and safe surface.

Another significant industrial application is in the fabrication of molds and tooling. Epoxy sheets can be machined, shaped, and polished to create precise molds for various manufacturing processes. Their dimensional stability ensures that these molds maintain their shape over repeated use, contributing to consistent product quality.

Aerospace and Automotive

The aerospace industry relies heavily on epoxy sheets for their exceptional strength-to-weight ratio and thermal stability. These materials are used in the construction of aircraft interiors, including flooring, bulkheads, and overhead compartments. Epoxy sheets contribute to reducing the overall weight of aircraft, thereby improving fuel efficiency without compromising on strength or safety.

In satellite and space applications, epoxy sheets are used for thermal insulation and as structural components. Their ability to withstand extreme temperature variations and resist outgassing in vacuum environments makes them invaluable in space technology.

The automotive industry also leverages the properties of epoxy sheets in various components. They are used in the production of lightweight body panels, interior trim, and under-hood components. The sheets' resistance to chemicals and heat makes them suitable for applications near engines and exhaust systems.

Electronics and Electrical Engineering

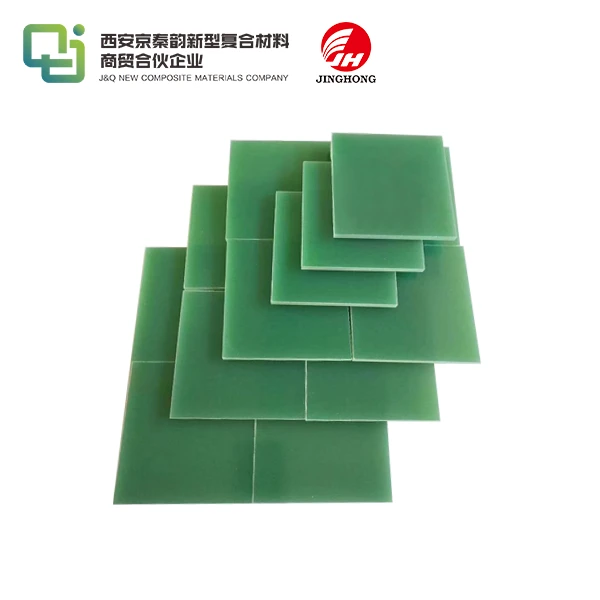

Epoxy sheets play a crucial role in the electronics industry, particularly in the manufacture of printed circuit boards (PCBs). Their excellent electrical insulation properties, combined with dimensional stability and heat resistance, make them an ideal substrate for PCBs. Epoxy sheets can withstand the high temperatures involved in soldering processes without warping or degrading.

In electrical engineering, epoxy sheets are used to create insulators, bushings, and switchgear components. Their high dielectric strength and arc resistance make them suitable for high-voltage applications. These materials are also used in the production of transformers and motor windings, where their electrical and thermal properties contribute to improved efficiency and longevity.

Epoxy sheets are also utilized in the manufacturing of encapsulation and potting compounds for electronic components. These compounds protect sensitive electronics from environmental factors such as moisture, dust, and vibration, ensuring reliable operation in challenging conditions.

Benefits of Using Epoxy Sheets

Cost-Effectiveness

While the initial cost of epoxy sheets may be higher compared to some traditional materials, their long-term cost-effectiveness is undeniable. The durability and longevity of epoxy sheets result in reduced maintenance and replacement costs over time. In industrial applications, this translates to fewer production interruptions and lower lifecycle costs.

The versatility of epoxy sheets also contributes to their cost-effectiveness. A single type of epoxy sheet can often replace multiple materials in various applications, streamlining inventory management and reducing procurement costs. Additionally, the lightweight nature of these sheets can lead to savings in transportation and installation costs, particularly in large-scale projects.

Furthermore, the energy efficiency gained from using epoxy sheets in certain applications, such as in aerospace or automotive industries, can result in significant cost savings over the lifespan of the product. The reduced weight contributes to fuel savings, while the thermal insulation properties can lead to energy conservation in buildings and industrial processes.

Customization Options

One of the most significant advantages of epoxy sheets is their adaptability to specific requirements. Manufacturers can tailor the properties of epoxy sheets by adjusting the resin formulation, curing process, and reinforcement materials. This customization allows for the creation of sheets with specific characteristics suited to unique applications.

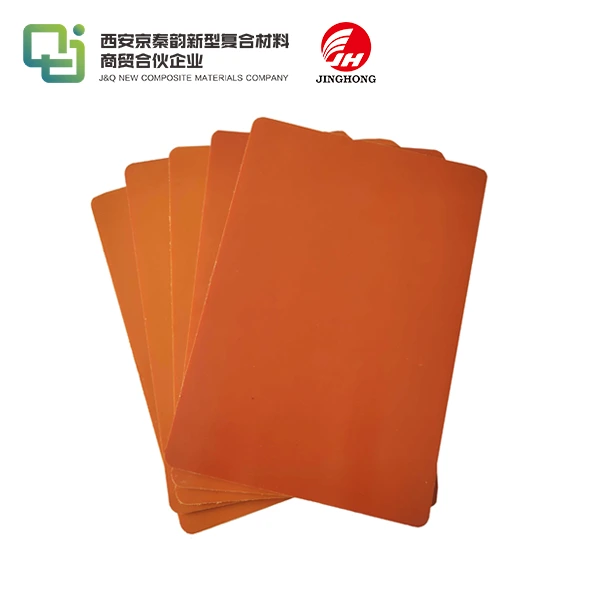

Color customization is another valuable option. Epoxy sheets can be produced in a wide range of colors and finishes, from transparent to opaque, and from matte to high-gloss. This versatility is particularly beneficial in architectural and design applications, where aesthetics play a crucial role alongside functionality.

Epoxy sheets can also be reinforced with various materials such as glass fibers, carbon fibers, or aramid fibers to enhance specific properties. For instance, glass-reinforced epoxy sheets offer improved strength and rigidity, while carbon fiber reinforcement can significantly boost the strength-to-weight ratio for aerospace applications.

Environmental Considerations

As sustainability becomes increasingly important across industries, the environmental aspects of epoxy sheets are worth considering. While traditional epoxy resins are derived from petroleum products, there is a growing trend towards bio-based epoxies made from renewable resources such as plant oils. These eco-friendly alternatives offer similar performance characteristics while reducing the carbon footprint.

The durability and longevity of epoxy sheets contribute to their environmental benefits. Their resistance to degradation means they need to be replaced less frequently, reducing waste and resource consumption over time. In applications such as protective coatings or linings, epoxy sheets can extend the life of other materials, further conserving resources.

Epoxy sheets also play a role in energy efficiency. Their use in lightweight structures, particularly in transportation, contributes to reduced fuel consumption and lower emissions. In building applications, epoxy-based materials can enhance thermal insulation, leading to energy savings in heating and cooling.

Conclusion

Epoxy sheets stand as a testament to modern materials science, offering a unique combination of properties that make them indispensable across various industries. Their exceptional strength, chemical resistance, and electrical insulation properties, coupled with their versatility and customization options, position them as a material of choice for engineers and designers. As we continue to push the boundaries of technology and sustainability, epoxy sheets will undoubtedly play a crucial role in shaping the future of manufacturing, construction, and innovation. The ongoing research and development in epoxy technology promise even more advanced and sustainable solutions, ensuring that these remarkable materials will continue to meet the evolving needs of industry and society.

Contact Us

If you're interested in exploring how epoxy sheets can benefit your specific application or if you have any questions about our range of insulating materials, we'd be delighted to assist you. Our team of experts is ready to provide personalized guidance and solutions tailored to your needs. Contact us today at info@jhd-material.com to discover the potential of epoxy sheets for your projects.

References

1. Johnson, A. R., & Smith, B. T. (2019). Advanced Epoxy Resins: Properties and Applications in Modern Engineering. Journal of Materials Science, 54(15), 10721-10735.

2. Zhang, L., & Wang, Y. (2020). Epoxy Composites: Fabrication, Properties, and Industrial Applications. Composites Science and Technology, 181, 107678.

3. Brown, C. D., & Davis, E. F. (2018). Electrical Properties of Epoxy-Based Insulation Materials for High-Voltage Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 25(3), 1178-1184.

4. García-Moreno, F., & Koltzenburg, S. (2021). Sustainable Epoxy Resins: Recent Advances and Future Perspectives. Progress in Polymer Science, 114, 101355.

5. Thompson, R. J., & Wilson, M. K. (2017). Epoxy Sheets in Aerospace: Lightweight Solutions for High-Performance Aircraft. Aerospace Engineering and Technology, 12(4), 345-358.

6. Lee, H. S., & Park, J. Y. (2020). Chemical Resistance of Epoxy-Based Materials: A Comprehensive Review. Corrosion Science, 158, 108073.