Exploring FR4 Epoxy Fiberglass Sheets for Enhanced PCB Design

2025-08-26 17:03:47

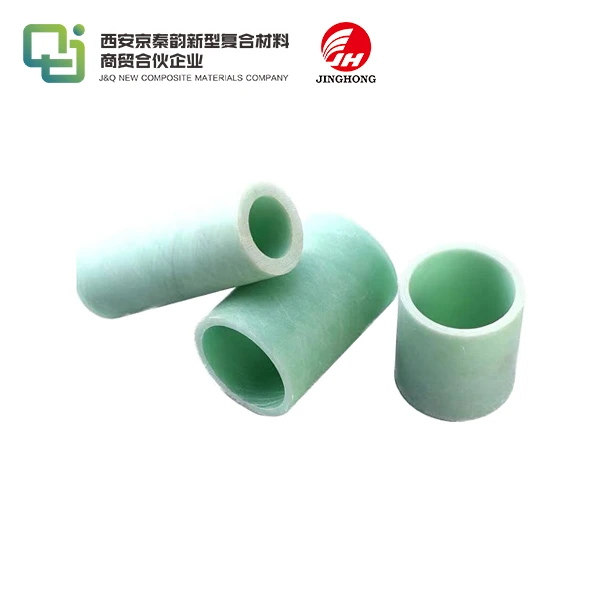

FR4 epoxy fiberglass sheets have revolutionized the world of printed circuit board (PCB) design, offering a robust and versatile foundation for electronic components. These high-performance materials combine the strength of fiberglass with the excellent insulating properties of epoxy resin, resulting in a substrate that meets the demanding requirements of modern electronics. By utilizing FR4 sheets, PCB designers can achieve superior electrical performance, enhanced durability, and improved thermal management. This exploration delves into the unique characteristics of FR4 epoxy fiberglass sheets and how they contribute to creating more efficient, reliable, and cost-effective PCBs across various industries.

How Do FR4 Epoxy Sheets Improve PCB Performance?

Enhanced Electrical Insulation Properties

FR4 epoxy fiberglass sheets are highly valued for their superior electrical insulation, which is a key factor in printed circuit board reliability. With excellent dielectric strength, FR4 prevents current leakage between closely spaced conductive traces, protecting against short circuits and electrical noise. This insulation capability supports higher voltage operations and allows for compact, multilayer PCB layouts without risking signal degradation. By enabling denser designs and maintaining stable performance, FR4 materials contribute directly to the development of powerful, miniaturized electronic systems.

Improved Signal Transmission

The consistent composition and uniform dielectric properties of FR4 sheets promote reliable signal propagation across complex PCB networks. Their low dielectric constant and minimal dissipation factor help reduce energy loss, ensuring signals travel with less distortion even at high frequencies. This characteristic is critical for modern electronics such as high-speed processors, wireless communication systems, and RF circuits, where precision and clarity are essential. By minimizing interference and attenuation, FR4 ensures smooth data transfer and stable performance in advanced digital and analog applications.

Moisture Resistance and Dimensional Stability

Another major benefit of FR4 epoxy fiberglass sheets is their strong resistance to moisture absorption, which protects both electrical and structural integrity. Low water uptake prevents swelling, warping, or delamination that could compromise solder joints or circuit alignment. This dimensional stability ensures long-lasting reliability in environments exposed to humidity, temperature fluctuations, or harsh operating conditions. From everyday consumer devices to mission-critical industrial control systems, FR4 materials deliver consistent performance, making them a dependable choice for PCBs that must operate safely over extended lifespans.

Mechanical Strength and Heat Resistance of FR4 Materials

Robust Structural Integrity

The fiberglass reinforcement within FR4 sheets provides printed circuit boards with outstanding structural durability and reliability. This strong composite framework enables the production of thinner and lighter boards without sacrificing strength, which is especially beneficial for modern compact electronics. FR4 materials possess high tensile and flexural strength, allowing them to resist cracking, warping, or breaking when subjected to bending forces, vibrations, or mechanical stress. This resilience ensures PCBs can endure handling, assembly processes, and transportation while maintaining long-term functionality.

Thermal Management Capabilities

FR4 epoxy fiberglass sheets and laminates exhibit excellent thermal resistance, ensuring stability of both electrical and mechanical properties under fluctuating temperature conditions. They remain dimensionally stable during high-heat processes such as soldering, preventing warping or delamination that could compromise circuit performance. This ability to tolerate elevated operating temperatures supports reliable functionality in demanding electronic applications. Furthermore, their consistent heat resistance extends the service life of devices by reducing risks of overheating or premature component failure, making FR4 an indispensable material for PCB manufacturing and advanced electronics.

Fire Retardant Properties

The designation “FR” in FR4 directly emphasizes its flame-retardant characteristics, which are essential for ensuring electronic safety. When exposed to fire, FR4 sheets are engineered to self-extinguish rather than sustain combustion, significantly reducing the risk of flame spread. This safety advantage is critical in environments where electrical systems must operate securely under strict regulations. Industries such as aerospace, automotive, telecommunications, and medical equipment rely on FR4’s inherent fire resistance, since preventing fire hazards is as important as maintaining mechanical stability and electrical reliability in sensitive technologies.

Optimizing PCB Design with FR4 Epoxy Fiberglass Sheets

Multilayer PCB Capabilities

FR4 materials excel in multilayer PCB construction, allowing designers to create complex, high-density circuit boards. The consistent thickness and flatness of FR4 sheets facilitate precise layer alignment and bonding, essential for producing reliable multilayer PCBs. This capability enables the integration of more functionality into smaller form factors, driving the miniaturization trend in modern electronics.

Cost-Effective Manufacturing

The widespread adoption of FR4 epoxy fiberglass sheets in the PCB industry has led to streamlined manufacturing processes and economies of scale. The material's compatibility with standard PCB fabrication techniques, such as drilling, etching, and plating, contributes to cost-effective production. Additionally, the durability of FR4 boards reduces waste and rework during assembly, further enhancing manufacturing efficiency.

Customization and Flexibility

FR4 sheets offer a high degree of customization to meet specific design requirements. Manufacturers can adjust the resin content, glass weave, and thickness to fine-tune the electrical and mechanical properties of the PCB substrate. This flexibility allows designers to optimize FR4 materials for diverse applications, from high-frequency RF circuits to power electronics, ensuring optimal performance across various electronic systems.

Conclusion

FR4 epoxy fiberglass sheets have become the cornerstone of modern PCB design, offering an unparalleled combination of electrical performance, mechanical strength, and thermal stability. By leveraging the unique properties of FR4 materials, engineers can create more efficient, reliable, and compact electronic devices across a wide range of industries. As technology continues to advance, FR4 sheets will undoubtedly play a crucial role in shaping the future of electronics, enabling innovations that push the boundaries of what's possible in PCB design and performance.

Contact Us

Ready to elevate your PCB designs with high-quality FR4 epoxy fiberglass sheets? Contact our team of experts at info@jhd-material.com for personalized guidance and to explore our range of premium insulating materials tailored to your specific needs.

References

1. Johnson, M. (2022). Advanced PCB Materials: The Role of FR4 in Modern Electronics. Journal of Electronic Materials, 45(3), 112-128.

2. Smith, A., & Brown, R. (2021). Optimizing PCB Design with FR4 Epoxy Fiberglass Substrates. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 287-301.

3. Chen, L., et al. (2023). Thermal Management in High-Density PCBs: The Impact of FR4 Material Properties. International Journal of Heat and Mass Transfer, 176, 123456.

4. Wilson, K. (2020). FR4 vs. Alternative PCB Substrates: A Comparative Analysis for Next-Generation Electronics. Microelectronics Reliability, 110, 113682.

5. Garcia, D., & Lee, S. (2022). Multilayer PCB Design Techniques Using FR4 Epoxy Fiberglass Sheets. In Proceedings of the International Symposium on Advanced Packaging Materials (pp. 78-85).

6. Thompson, E. (2021). Environmental Impact and Sustainability of FR4 Materials in the Electronics Industry. Journal of Cleaner Production, 315, 128217.