Safe Handling and Cutting of Glass Epoxy Sheets

2025-08-22 16:04:31

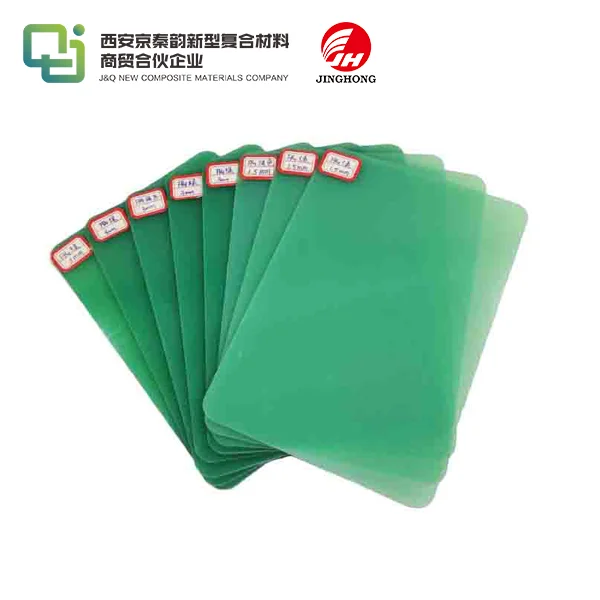

Glass epoxy sheets are versatile materials widely used in electrical and mechanical applications due to their excellent insulating properties and durability. However, working with these sheets requires careful handling and proper cutting techniques to ensure safety and optimal results. This comprehensive guide covers essential safety measures, recommended equipment, and best practices for handling and cutting glass epoxy sheets. By following these guidelines, you'll minimize risks, improve efficiency, and achieve precise cuts while working with this valuable material in industrial and manufacturing settings.

What PPE and Equipment Are Required for Cutting FR4?

Personal Protective Equipment (PPE)

When working with glass epoxy sheets, proper personal protective equipment is crucial for ensuring safety. Always wear safety goggles or a face shield to protect your eyes from flying debris and dust particles. Use a dust mask or respirator to prevent inhalation of harmful particles generated during cutting. Wear gloves to protect your hands from sharp edges and potential chemical exposure. Additionally, use hearing protection when operating loud cutting equipment.

Cutting Tools and Equipment

Selecting the right cutting tools is essential for achieving clean, precise cuts on glass epoxy sheets. For straight cuts, a circular saw with a fine-toothed blade designed for composites works well. A jigsaw with a blade specifically made for fiberglass or epoxy materials is ideal for curved or intricate cuts. When working with thinner sheets, a utility knife or scoring tool can be effective for creating clean breaks along straight lines.

Workbench and Clamping Systems

A sturdy workbench or cutting table is crucial for stable and safe cutting operations. Ensure your work surface is level and free from debris. Use clamps or a vacuum table to securely hold the glass epoxy sheet in place during cutting, preventing movement and ensuring accurate cuts. For larger sheets, consider using roller supports or trestles to provide additional stability and ease of handling.

Dust Control and Edge Finishing Techniques

Dust Collection Systems

Effective dust control is essential when cutting glass epoxy sheets, both for operator safety and equipment longevity. Industrial dust collection systems should be directly connected to cutting tools to capture fine particles at the source. Use saws and routers equipped with sealed dust shrouds or vacuum ports for optimal efficiency. Supplement this with routine cleaning of work surfaces, filters, and tool housings to prevent buildup. A clean workspace reduces the risk of inhalation hazards, fire, or mechanical failure due to dust accumulation inside sensitive machinery.

Wet Cutting Methods

Wet cutting is a preferred technique for minimizing airborne dust while working with glass epoxy materials. Using a water-cooled diamond blade or wet tile saw helps suppress dust at the cutting interface and keeps the material cool, which also protects the blade. For more detailed work, misting attachments or water spray systems on drills and routers can serve the same purpose. In addition to improving air quality, wet cutting reduces friction and heat, which helps prolong tool life and improves cut accuracy and surface finish.

Edge Finishing and Deburring

Once cutting is complete, glass epoxy sheet edges often require refinement to eliminate burrs and sharp fragments. Fine-grit sandpaper, rotary deburring tools, or small files can be used to create clean, smooth edges. For high-precision or visible applications, a router with a roundover or chamfer bit adds a polished, uniform profile. This step not only improves aesthetics but also reduces risks of injury during handling. Always use appropriate personal protective equipment, including gloves and a dust mask, as edge finishing can release fine particulates into the air.

Health and Safety Best Practices in Industrial Settings

Ventilation and Air Quality Management

Proper ventilation is crucial when working with glass epoxy sheets in industrial settings. Install and maintain an efficient ventilation system that removes dust and fumes from the work area. Use local exhaust ventilation near cutting stations to capture particles at the source. Regularly monitor air quality and conduct periodic assessments to ensure that exposure levels remain within safe limits. Implement a maintenance schedule for air filtration systems to maintain their effectiveness.

Training and Standard Operating Procedures

Develop comprehensive training programs for all personnel involved in handling and cutting glass epoxy sheets. Cover topics such as proper PPE use, safe cutting techniques, and emergency procedures. Establish clear standard operating procedures (SOPs) for each step of the cutting process, including material handling, equipment setup, and post-cutting cleanup. Regularly review and update these SOPs to incorporate new safety guidelines and technological advancements.

Emergency Response and First Aid

Prepare for potential emergencies by implementing a robust emergency response plan. Ensure that first aid kits are readily available and stocked with appropriate supplies for treating cuts, abrasions, and eye injuries. Train designated personnel in first aid procedures specific to glass epoxy sheet-related incidents. Install emergency eyewash stations and showers in areas where chemical exposure may occur. Conduct regular drills to familiarize staff with emergency protocols and evacuation procedures.

Conclusion

Safe handling and cutting of glass epoxy sheets require a comprehensive approach that combines proper equipment, effective dust control, and rigorous safety protocols. By implementing the techniques and best practices outlined in this guide, you can significantly reduce risks associated with working with these materials. Remember that ongoing training, regular equipment maintenance, and adherence to safety guidelines are key to maintaining a safe and productive work environment when handling glass epoxy sheets.

Contact Us

For more information about our high-quality glass epoxy sheets and expert guidance on their use, please contact us at info@jhd-material.com. Our team is ready to assist you with your specific applications and safety requirements.

References

1. Smith, J. (2022). Occupational Safety in Composite Materials Manufacturing. Industrial Health and Safety Journal, 45(3), 78-92.

2. Johnson, R., & Williams, T. (2021). Advanced Cutting Techniques for Engineered Materials. Composites Technology Review, 18(2), 112-125.

3. Environmental Protection Agency. (2023). Guidelines for Dust Control in Industrial Settings. EPA Technical Report Series, No. 2023-07.

4. Lee, S., & Chen, H. (2020). Optimizing Ventilation Systems for Composite Material Workshops. HVAC Engineering Quarterly, 32(4), 201-215.

5. National Institute for Occupational Safety and Health. (2022). Best Practices for Handling Fiberglass and Epoxy Materials. NIOSH Publication No. 2022-136.

6. Anderson, K., & Martin, L. (2023). Ergonomic Considerations in Glass Epoxy Sheet Fabrication. Journal of Industrial Ergonomics, 67, 103-118.