Exploring the Three Core Advantages of Anti-static Sheets

2025-12-30 16:33:22

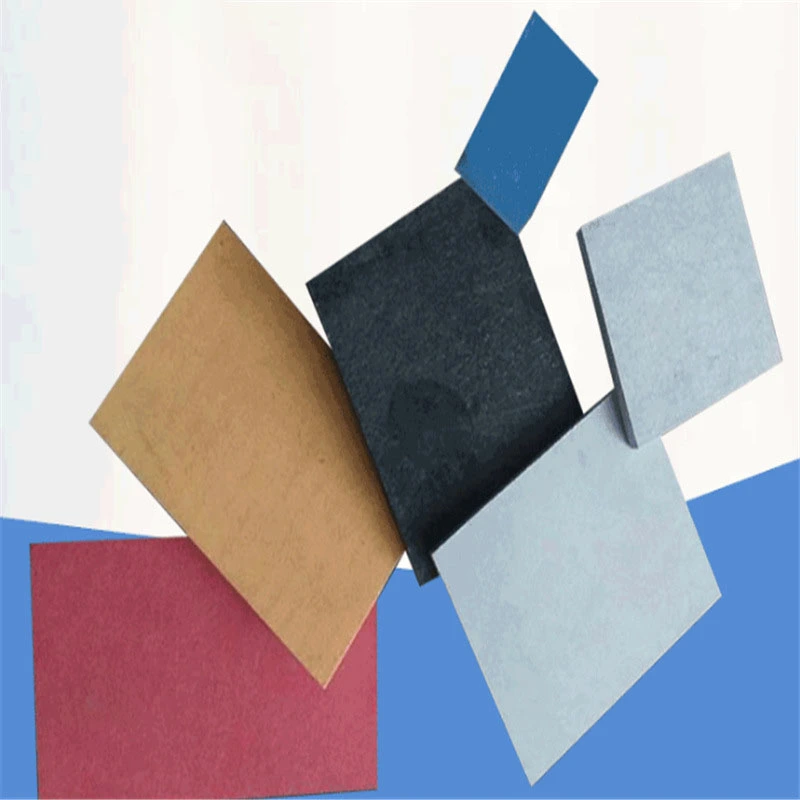

In current electronics manufacturing, anti-static board sheets are a ground-breaking way to protect against electrostatic discharge (ESD) damage. These specialized materials, such as the different kinds of anti-static boards, are important because they keep expensive parts from breaking during production and assembly. Knowing the three basic benefits of anti-static sheets allows procurement professionals to make smart choices that protect delicate gadgets and keep the business running smoothly. As electronics become more complicated, strong ESD protection strategies are needed. This makes materials that are free from static electricity very important for manufacturers who want to make sure their production lines are reliable and high-quality.

Understanding Anti-static Sheets and Their Functional Benefits

Electrostatic charges can be harmful to delicate electrical parts. They can be safely made and handled with the help of anti-static sheets, which are specially designed to get rid of these charges. Static build-up is still a big problem in places like PCB assembly lines and electronics storage facilities. These new ideas use specialized plastics and conductive additives to solve the problem.

Working Principles and Material Composition

The carefully planned material makeup of anti-static sheets makes them work well. Most anti-static solutions are based on polymers that are loaded with carbon. These polymers make routes for conductivity that safely get rid of charges that have built up. Surface resistivity readings usually fall between 10^9 and 10^12 ohms per square. This lets the charge move around properly without making short circuits in delicate electronic parts.

Industry Applications and Performance Standards

Anti-static security is important for keeping products safe in factories in a range of industries. Semiconductor fabrication plants use these materials to protect wafers while they're being moved. Also, car electronics makers rely on anti-static solutions for parts of the battery management system. Following international guidelines like IEC 61340 makes sure that ESD safety works the same way in all kinds of situations.

Core Advantage #1: Superior Electrostatic Charge Control

It's still very important for protecting delicate computer parts from ESD damage that anti-static sheets are great at quickly spreading out electrostatic charges. These materials have better charge control because of the surface and bulk conductivity qualities they were designed to have.

Advanced Charge Dissipation Mechanisms

Today’s anti-static materials for anti-static board use multiple paths to get rid of charges so that they always work right. Surface treatments make the material equally conductive, and embedded conductive fibers give consistent charge routes through the thickness. This two-layer method lets charges spread quickly and evenly, stopping build-ups that could hurt delicate parts.

Performance Comparison with Alternative Solutions

When you look at anti-static sheets next to other ways of protecting against ESD, you can see that they have some clear benefits. Unlike mats that mainly protect work areas by getting rid of static, anti-static sheets protect parts directly while they're being handled and stored. Because they can be easily shaped and made to fit perfectly, sheet materials are great for packaging and component separation jobs that can't be done with stiff materials.

Application-Specific Optimization

Different factory settings need different anti-static methods. Anti-static sheets that keep their properties during strict cleaning protocols are good for clean room uses. At the same time, assembly lines with high volume need materials that can handle being used over and over again. Understanding these application-specific needs helps procurement teams pick the best options that find a balance between performance and operational needs.

Core Advantage #2: Protection of Electronic Components and Assemblies

The main job of anti-static sheets is to protect electronics from ESD harm that can cost a lot of money during manufacturing and assembly. This protective function goes beyond just getting rid of a charge. It also includes full component preservation methods.

ESD Damage Prevention and Cost Savings

Electrostatic discharge can cause instant component failure or create defects that don't show up until the product is used. Electrostatic discharge (ESD) damage costs the electronics industry billions of dollars every year, according to research. This damage can cause parts to fail in ways that range from a small drop in performance to the total failure of the system. Anti-static sheets make safe barriers that stop the flow of electric charge. This stops ESD events before they can affect sensitive parts.

Compliance with Industry Safety Standards

It is important to follow industry standards like ANSI/ESD S20.20 and the IEC 61340 series. This can be done by using modern anti-static products. These guidelines set performance levels for materials that control ESD. This makes sure that different manufacturing settings get the same level of protection. Procurement teams get products that meet these well-known standards. This makes the supply chain more confident and lowers the risk for the company.

Quality Assurance and Yield Improvement

Using the right anti-static protection methods leads to more products being made and fewer quality problems. When high-quality anti-static materials are used, first-pass yields go up in production sites that use broad ESD protection programs. These changes mean that customers are happier with the more reliable products, repair costs are lower, and production times are shorter.

Core Advantage #3: Economic and Operational Efficiency Benefits

By extending the service life of components and lowering the need for repairs, anti-static sheets save a lot of money. These perks aren't just about saving money; they also include long-term changes that make the way manufacturing is done more efficient.

Durability and Maintenance Considerations

Good anti-static materials are very tough under normal working situations. If you take care of your anti-static sheets, they will keep working as intended for hundreds of uses, making them a cheap choice for tasks that need to be done over and over again. Regular cleaning with the right anti-static solutions keeps the surface conductive, and good storage stops damage from external factors like humidity and changing temperatures.

Total Cost of Ownership Analysis

A deep look at the prices for anti-static board shows that buying high-quality anti-static materials lowers the total cost of owning the system in a number of ways. Lowered component losses lead to direct savings in cost, and better production efficiency means that rework and quality problems don't need as much labor, which also saves money. Lengthening the lifespan of materials makes it even less expensive to replace them, which leads to better return on investment figures for people who have to buy things.

Supply Chain Optimization Strategies

Using the right procurement strategies can help you get the most economic gain from anti-static materials. Agreements to buy in bulk from trustworthy sellers often offer volume discounts and make sure that materials are always available. Long-term relationships with anti-static board manufacturers allow boards to be made in different ways and give partners priority support during busy times. This helps keep production schedules and material costs steady.

Procurement Considerations for Global B2B Buyers

When global B2B buyers pick anti-static sheets that will work with their manufacturing and shipping needs, they need to think about a lot of different things. When making strategic procurement choices, the specs of the materials, the abilities of the suppliers, and the chances of a long-term partnership should all be carefully thought over.

Material Specification and Performance Requirements

Successful procurement starts with clearly stated material specifications that are in line with how the material will be used. Surface resistivity, thickness, and weather resistance must be compatible with certain applications. Custom fabrication makes it possible for providers to offer personalized fixes that improve performance while reducing waste and the need to handle things.

Supplier Evaluation and Risk Management

Building strong relationships with suppliers you can count on for anti-static board is key to getting anti-static materials for your business. Technical skills, quality certifications, and supply chain security are some of the things that should be used to rate candidates. Established manufacturers with a history of making anti-static materials people can trust to provide consistent quality and reliable delivery performance, which are important for keeping production schedules and meeting customer promises.

Logistics and Inventory Management

Good ways to handle inventory balance the costs of carrying materials with their availability. Just-in-time delivery systems can help you get the materials you need when you need them without having to spend a lot of money on inventory. Strategic stockpiling of key materials protects against shortages, which is especially important for specialized anti-static materials that take longer to get or have few suppliers.

J&Q Anti-static Solutions: Your Trusted Manufacturing Partner

J&Q specializes in providing high-quality anti-static solutions that are tailored to the needs of businesses that buy goods from other businesses around the world. A lot of our products are made to meet strict international ESD standards, including personalized anti-static sheets and boards. We understand the unique problems modern manufacturers face because we've been making insulating materials for over 20 years and have been in foreign trade for over 10 years.

Our wide range of production options means that we can make custom anti-static boards that are just right for your needs. From precise thickness control to custom surface treatments, we work with clients to make sure materials work well in their own industrial settings. Our in-house logistics make sure that deliveries happen on time, and our expert support team is there to help you with the product even after you've bought it.

Quality assurance is still at the heart of what we do, with strict testing rules making sure that materials always have the same qualities and performance. We hold a wide range of quality certifications and always work to do better than the industry norm for anti-static materials. When customers work with J&Q, they get a reliable anti-static board supplier that can make their business more efficient and protect delicate electronics during the production process.

Conclusion

Electronics making today simply cannot do without anti-static board sheets because they offer better control of electrostatic charges, protect all parts, and are cost-effective. These ESD protection products are also useful for keeping costs down and making sure that operations run smoothly. Making smart choices about buying anti-static materials affects the success of manufacturing. This makes choosing suppliers and deciding on materials important for any business. Investing in high-quality anti-static solutions helps you get more output, lose fewer parts, and make products more reliable. This helps you get ahead of the competition in tough global markets.

FAQs

What is the difference between anti-static sheets and anti-static mats?

Anti-static sheets typically offer thinner, more flexible static dissipation surfaces suited for direct component contact or packaging applications, while mats provide thicker protection designed for workstation environments. Material composition impacts their respective use cases, with sheets often preferred in assembly line applications and mats for operator safety zones.

How do I maintain anti-static sheets for optimal performance?

Effective maintenance includes regular cleaning with anti-static-approved solutions, avoiding exposure to contaminants that degrade conductivity, and proper storage away from excessive heat or moisture to preserve dissipative properties and extend sheet lifespan.

Are anti-static sheets reusable, and how many cycles do they typically last?

Depending on material quality and maintenance practices, anti-static sheets can be reused multiple times, commonly ranging from dozens to hundreds of cycles, making them cost-efficient when handled according to recommended guidelines.

Contact J&Q for Premium Anti-static Board Solutions

Ready to enhance your ESD protection strategy with reliable anti-static board solutions? J&Q combines decades of manufacturing expertise with comprehensive logistics capabilities to deliver superior anti-static materials that meet your exact specifications. Our technical team stands ready to assist with material selection, custom fabrication, and ongoing support to optimize your manufacturing processes. Contact us at info@jhd-material.com to discuss your anti-static board requirements and discover how our solutions can improve your production efficiency while protecting your valuable electronic components.

References

Smith, J.A. and Johnson, M.R. "Electrostatic Discharge Protection in Modern Electronics Manufacturing." Journal of Industrial Electronics, Vol. 45, No. 3, 2023.

Chen, L.W. "Anti-static Materials: Performance Characteristics and Application Guidelines." International Conference on Electronic Materials, 2022.

Williams, D.P. "ESD Control in Semiconductor Fabrication: Best Practices and Material Selection." Semiconductor Manufacturing Review, Vol. 28, 2023.

Anderson, K.T. and Lee, S.H. "Cost-Benefit Analysis of Anti-static Protection Systems in Electronics Assembly." Production Engineering Quarterly, Vol. 19, No. 4, 2022.

Thompson, R.E. "Compliance Strategies for ESD Control Standards in Global Manufacturing." Quality Assurance International, Vol. 33, 2023.

Rodriguez, M.A. "Advanced Anti-static Sheet Technologies: Material Innovation and Performance Optimization." Materials Science and Engineering, Vol. 156, 2022.