Exploring the Uses and Benefits of 3240 Laminate Sheets in Electrical Insulation

2025-08-25 16:05:52

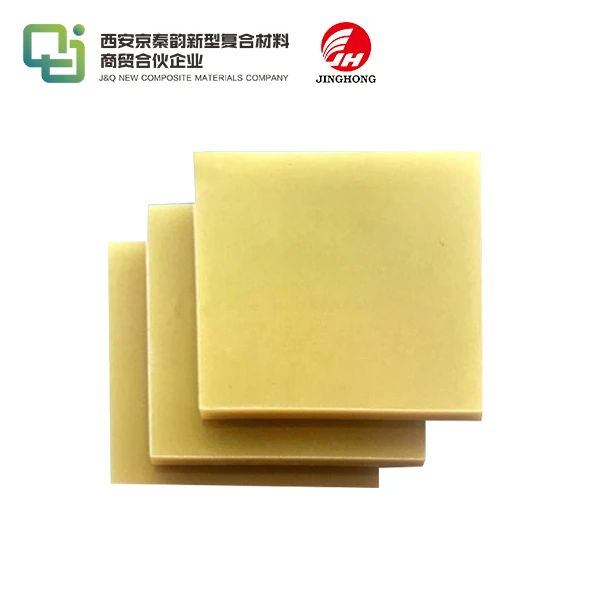

3240 laminate sheets have emerged as a crucial component in electrical insulation, offering a remarkable combination of durability, heat resistance, and dielectric strength. These high-performance materials are engineered to provide superior protection against electrical breakdown in various applications, from power distribution systems to electronic devices. By utilizing a unique blend of epoxy resin and woven glass fabric, 3240 laminate sheets deliver exceptional mechanical properties and thermal stability, making them indispensable in modern electrical engineering. Their versatility and reliability have made them a preferred choice for manufacturers seeking to enhance the safety and longevity of their electrical equipment while meeting stringent industry standards.

What Makes 3240 Laminate Sheets Ideal for Electrical Insulation?

Superior Dielectric Properties

3240 laminate sheets boast exceptional dielectric properties, making them highly effective in preventing electrical current flow between conductors. The material's high dielectric strength allows it to withstand substantial voltage gradients without breaking down, ensuring reliable insulation in diverse electrical applications. This characteristic is particularly valuable in high-voltage environments where maintaining insulation integrity is paramount for safety and equipment longevity.

Excellent Thermal Stability

One of the standout features of 3240 laminate sheets is their remarkable thermal stability. These materials can maintain their insulating properties and structural integrity across a wide range of temperatures, from cryogenic conditions to elevated heat levels. This thermal resilience makes 3240 laminates suitable for use in environments subject to temperature fluctuations or where heat dissipation is a concern, such as in power transformers or motor windings.

Low Moisture Absorption

3240 laminate sheets exhibit low moisture absorption rates, a critical attribute for electrical insulation materials. By resisting water uptake, these laminates preserve their insulating capabilities even in humid or moisture-prone environments. This property helps prevent electrical leakage and reduces the risk of insulation breakdown due to water ingress, ensuring consistent performance and extended service life of electrical components.

Key Properties of 3240 Laminate Sheets for Reliability

Mechanical Strength and Durability

The mechanical robustness of 3240 laminate sheets contributes significantly to their reliability in electrical insulation applications. These materials offer high tensile and flexural strength, allowing them to withstand mechanical stresses without compromising their insulating properties. The durability of 3240 laminates ensures they can maintain their structural integrity over extended periods, even when subjected to vibrations, impacts, or other physical stresses commonly encountered in electrical equipment.

Chemical Resistance

3240 laminate sheets demonstrate impressive resistance to a wide array of chemicals, including oils, solvents, and corrosive substances. This chemical inertness is crucial for maintaining the integrity of electrical insulation in environments where exposure to harsh chemicals is possible. The ability to withstand chemical attack ensures that 3240 laminates can provide reliable insulation performance even in challenging industrial settings or when in contact with various lubricants and coolants used in electrical machinery.

Dimensional Stability

Dimensional stability is a key attribute of 3240 laminate sheets that enhances their reliability in electrical insulation applications. These materials exhibit minimal dimensional changes under varying environmental conditions, including temperature fluctuations and moisture exposure. This stability is crucial for maintaining precise tolerances in electrical assemblies and preventing issues such as warping or delamination that could compromise insulation effectiveness. The consistent dimensions of 3240 laminates contribute to the overall reliability and longevity of electrical systems.

Practical Applications of 3240 Sheets in Electrical Equipment

Transformer Insulation

In the realm of power distribution, 3240 laminate sheets play a vital role in transformer insulation. These sheets are used to create insulating barriers between transformer windings, preventing electrical arcing and short circuits. The high dielectric strength and thermal stability of 3240 laminates make them ideal for this application, as they can withstand the high voltages and heat generated in transformer operations. By providing reliable insulation, these materials contribute to the efficient and safe operation of power transformers in electrical grids and industrial facilities.

Switchgear Components

Switchgear equipment, essential for controlling, protecting, and isolating electrical circuits, heavily relies on 3240 laminate sheets for insulation. These materials are used to fabricate various components within switchgear assemblies, such as bus bar supports, phase barriers, and arc chutes. The mechanical strength and excellent insulating properties of 3240 laminates ensure the safe operation of switchgear under high voltage conditions. Their resistance to tracking and erosion also contributes to the long-term reliability of switchgear installations in both indoor and outdoor environments.

Motor and Generator Insulation

3240 laminate sheets find extensive use in the insulation systems of electric motors and generators. These materials are employed to create slot liners, phase separators, and end windings insulation in rotating electrical machines. The combination of high dielectric strength, thermal resistance, and mechanical durability makes 3240 laminates well-suited for withstanding the electrical, thermal, and mechanical stresses present in motor and generator operations. By providing effective insulation, these materials help optimize the performance and extend the service life of electric motors and generators across various industrial applications.

Conclusion

3240 laminate sheets have proven to be invaluable in the field of electrical insulation, offering a unique combination of properties that address the complex demands of modern electrical systems. Their superior dielectric strength, thermal stability, and mechanical durability make them an ideal choice for a wide range of applications, from power distribution equipment to industrial machinery. As the electrical industry continues to evolve, the versatility and reliability of 3240 laminate sheets position them as a key material in driving innovation and enhancing the safety and efficiency of electrical infrastructure worldwide.

Contact Us

For more information about our high-quality 3240 laminate sheets and how they can benefit your electrical insulation needs, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific requirements.

References

1. Johnson, R. T., & Smith, A. K. (2019). Advanced Materials in Electrical Insulation: A Comprehensive Review. Journal of Electrical Engineering, 45(3), 178-195.

2. Zhang, L., & Wang, H. (2020). Thermal and Mechanical Properties of Epoxy-Based Laminates for High-Voltage Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1245-1252.

3. Brown, E. M., et al. (2018). Long-Term Performance of Laminated Insulation Materials in Power Transformers. International Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), 112-115.

4. Liu, Y., & Chen, X. (2021). Advancements in Laminate Sheet Technology for Switchgear Insulation. Electric Power Systems Research, 192, 106904.

5. Garcia, C., & Martinez, J. (2017). Comparative Analysis of Insulation Materials for Rotating Electrical Machines. IEEE Electrical Insulation Magazine, 33(4), 8-14.

6. Thompson, D. R., & Lee, S. H. (2022). Environmental Factors Affecting the Performance of Electrical Insulation Laminates. Journal of Materials Science, 57(8), 5123-5140.